Question: PLEASE ANSWER IT'S ALL OF THESE ONLY ONE QUESTION ( CAN YOU PLEASE SHOW WORK FOR (A&C) Q2 International Cranberry (20 points) International Cranberry (IC)

PLEASE ANSWER IT'S ALL OF THESE ONLY ONE QUESTION ( CAN YOU PLEASE SHOW WORK FOR (A&C)

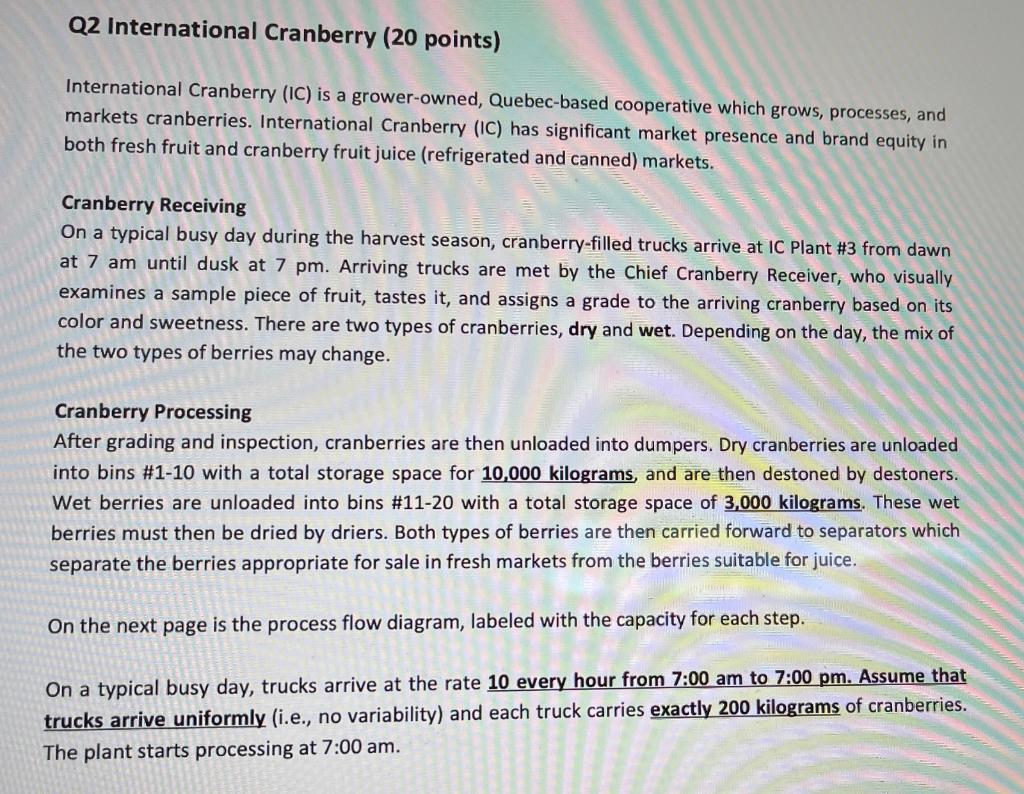

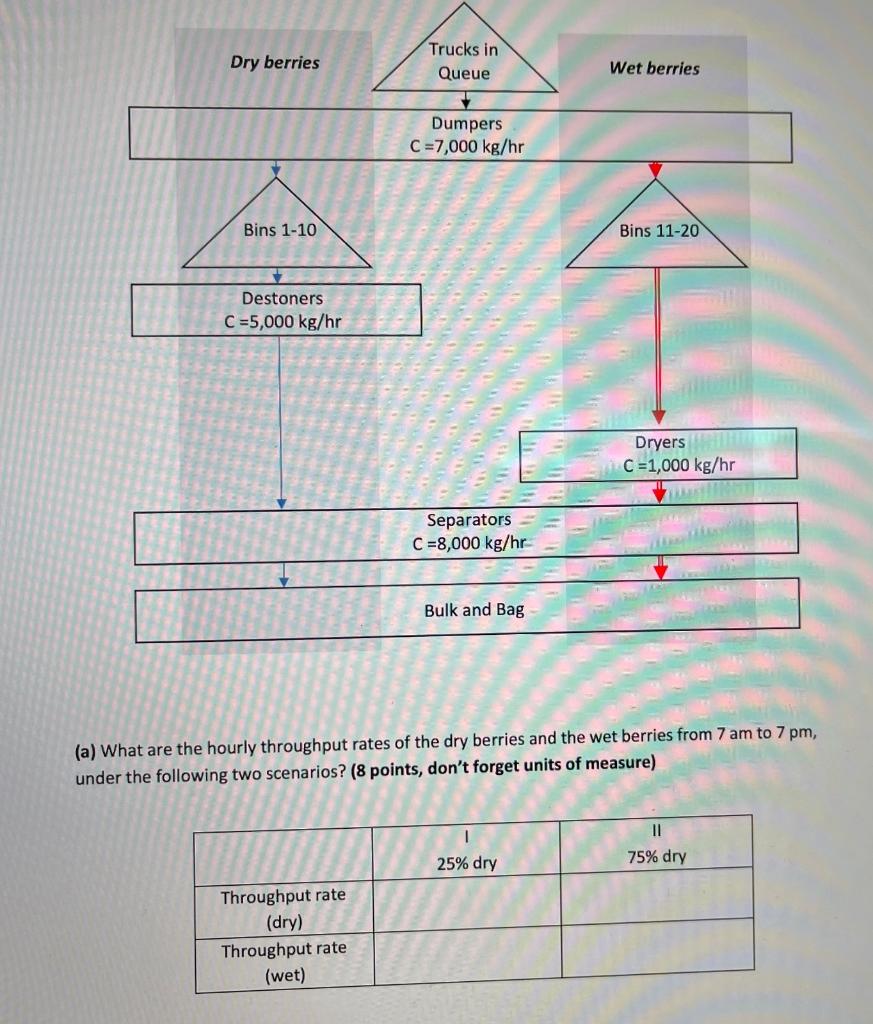

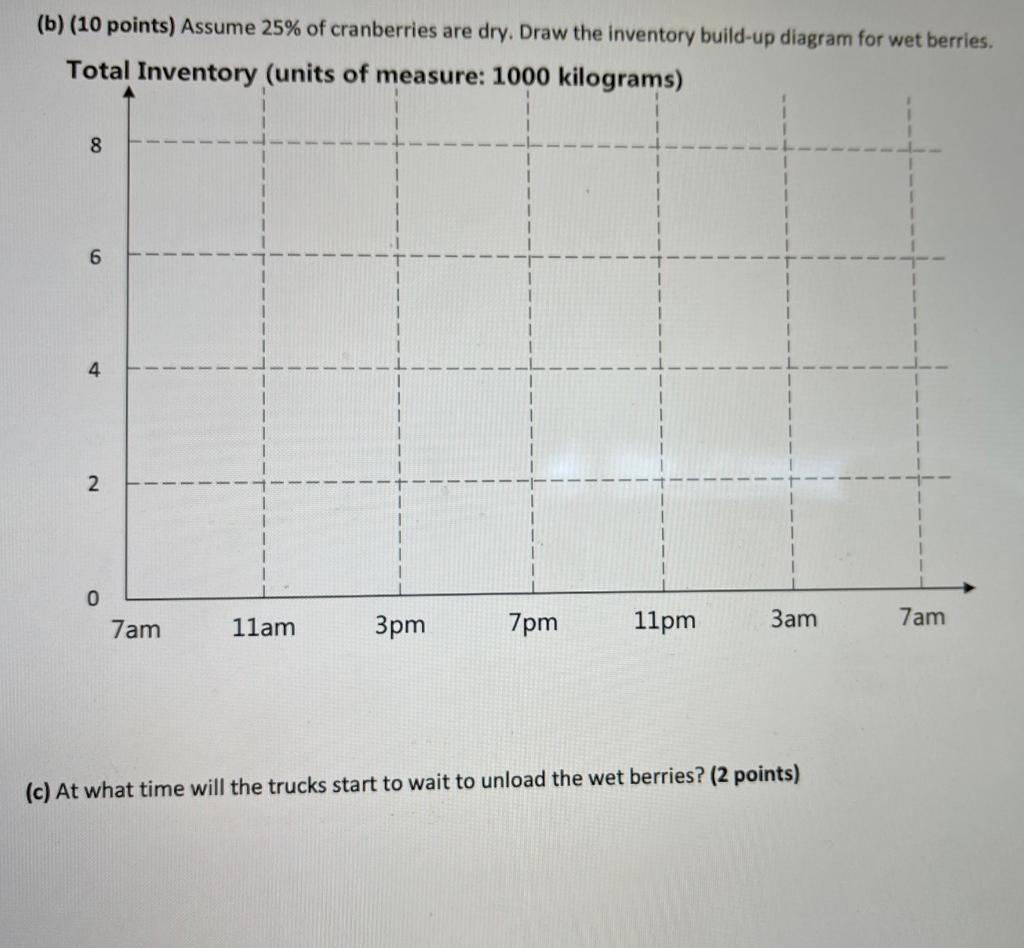

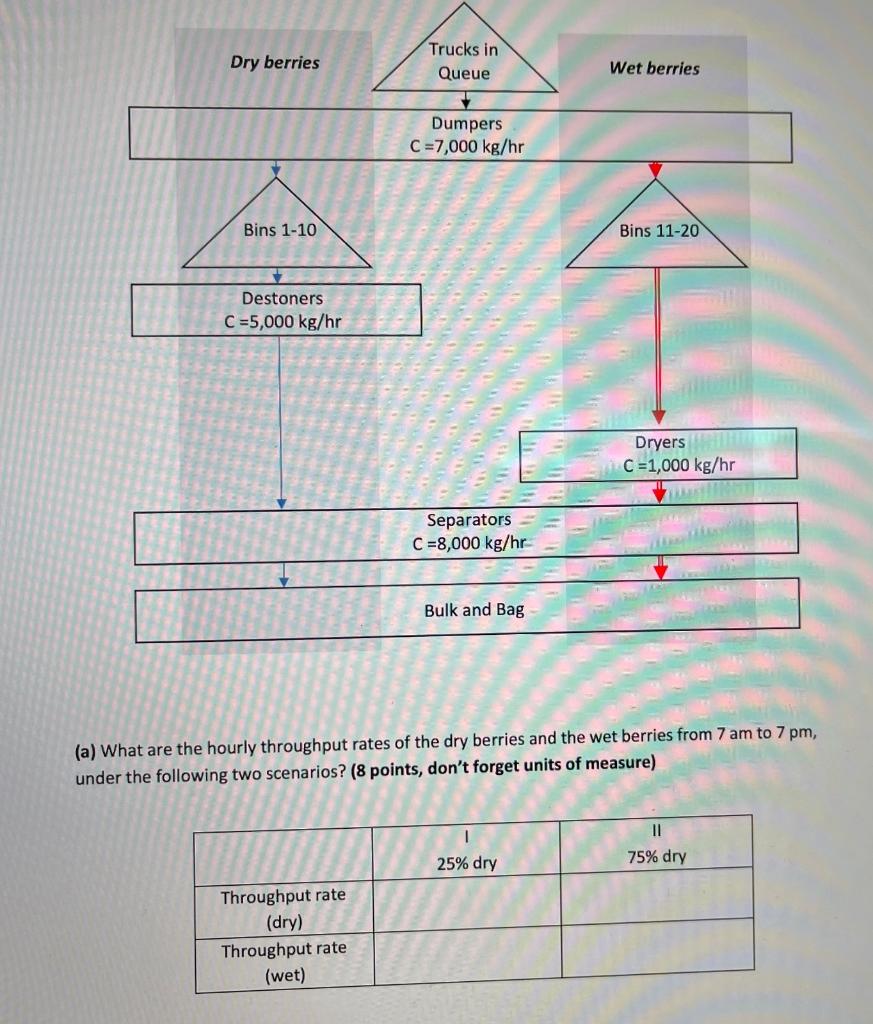

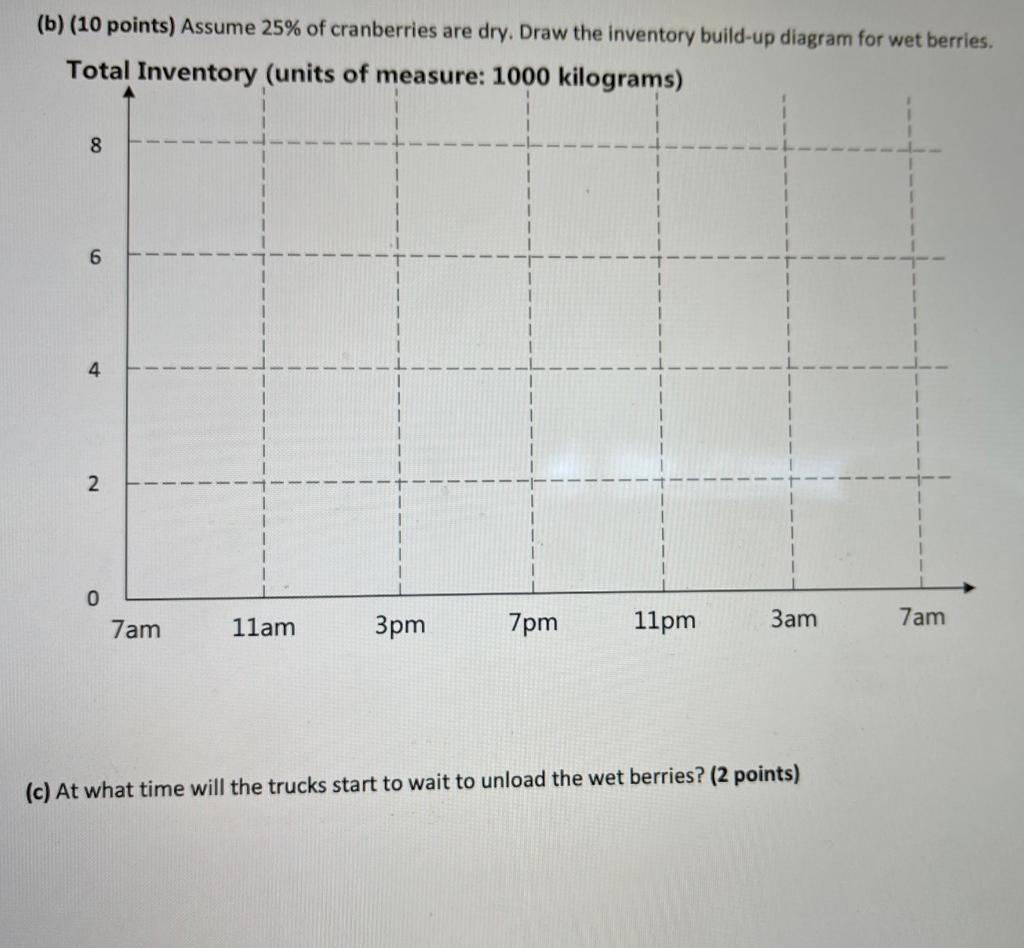

Q2 International Cranberry (20 points) International Cranberry (IC) is a grower-owned, Quebec-based cooperative which grows, processes, and markets cranberries. International Cranberry (IC) has significant market presence and brand equity in both fresh fruit and cranberry fruit juice (refrigerated and canned) markets. Cranberry Receiving On a typical busy day during the harvest season, cranberry-filled trucks arrive at IC Plant #3 from dawn at 7 am until dusk at 7 pm. Arriving trucks are met by the Chief Cranberry Receiver, who visually examines a sample piece of fruit, tastes it, and assigns a grade to the arriving cranberry based on its color and sweetness. There are two types of cranberries, dry and wet. Depending on the day, the mix of the two types of berries may change. Cranberry Processing After grading and inspection, cranberries are then unloaded into dumpers. Dry cranberries are unloaded into bins #1-10 with a total storage space for 10,000 kilograms, and are then destoned by destoners. Wet berries are unloaded into bins #11-20 with a total storage space of 3,000 kilograms. These wet berries must then be dried by driers. Both types of berries are then carried forward to separators which separate the berries appropriate for sale in fresh markets from the berries suitable for juice. On the next page is the process flow diagram, labeled with the capacity for each step. On a typical busy day, trucks arrive at the rate 10 every hour from 7:00 am to 7:00 pm. Assume that trucks arrive uniformly (i.e., no variability) and each truck carries exactly 200 kilograms of cranberries. The plant starts processing at 7:00 am. Dry berries Trucks in Queue Wet berries Dumpers C =7,000 kg/hr Bins 1-10 Bins 11-20 Destoners C =5,000 kg/hr Dryers C =1,000 kg/hr VS Separators C =8,000 kg/hr Bulk and Bag (a) What are the hourly throughput rates of the dry berries and the wet berries from 7 am to 7 pm, under the following two scenarios? (8 points, don't forget units of measure) II 75% dry 25% dry Throughput rate (dry) Throughput rate (wet) (b) (10 points) Assume 25% of cranberries are dry. Draw the inventory build-up diagram for wet berries. Total Inventory (units of measure: 1000 kilograms) 8 6 4 | 2. 0 7am 11am 7pm 7am 3pm 11pm 3am (c) At what time will the trucks start to wait to unload the wet berries? (2 points) Q2 International Cranberry (20 points) International Cranberry (IC) is a grower-owned, Quebec-based cooperative which grows, processes, and markets cranberries. International Cranberry (IC) has significant market presence and brand equity in both fresh fruit and cranberry fruit juice (refrigerated and canned) markets. Cranberry Receiving On a typical busy day during the harvest season, cranberry-filled trucks arrive at IC Plant #3 from dawn at 7 am until dusk at 7 pm. Arriving trucks are met by the Chief Cranberry Receiver, who visually examines a sample piece of fruit, tastes it, and assigns a grade to the arriving cranberry based on its color and sweetness. There are two types of cranberries, dry and wet. Depending on the day, the mix of the two types of berries may change. Cranberry Processing After grading and inspection, cranberries are then unloaded into dumpers. Dry cranberries are unloaded into bins #1-10 with a total storage space for 10,000 kilograms, and are then destoned by destoners. Wet berries are unloaded into bins #11-20 with a total storage space of 3,000 kilograms. These wet berries must then be dried by driers. Both types of berries are then carried forward to separators which separate the berries appropriate for sale in fresh markets from the berries suitable for juice. On the next page is the process flow diagram, labeled with the capacity for each step. On a typical busy day, trucks arrive at the rate 10 every hour from 7:00 am to 7:00 pm. Assume that trucks arrive uniformly (i.e., no variability) and each truck carries exactly 200 kilograms of cranberries. The plant starts processing at 7:00 am. Dry berries Trucks in Queue Wet berries Dumpers C =7,000 kg/hr Bins 1-10 Bins 11-20 Destoners C =5,000 kg/hr Dryers C =1,000 kg/hr VS Separators C =8,000 kg/hr Bulk and Bag (a) What are the hourly throughput rates of the dry berries and the wet berries from 7 am to 7 pm, under the following two scenarios? (8 points, don't forget units of measure) II 75% dry 25% dry Throughput rate (dry) Throughput rate (wet) (b) (10 points) Assume 25% of cranberries are dry. Draw the inventory build-up diagram for wet berries. Total Inventory (units of measure: 1000 kilograms) 8 6 4 | 2. 0 7am 11am 7pm 7am 3pm 11pm 3am (c) At what time will the trucks start to wait to unload the wet berries? (2 points)