Question: Please answer parts D and E only , show equations used if possible. Thank you!! Consider a line that makes two different digital TVs. The

Please answer parts D and E only, show equations used if possible. Thank you!!

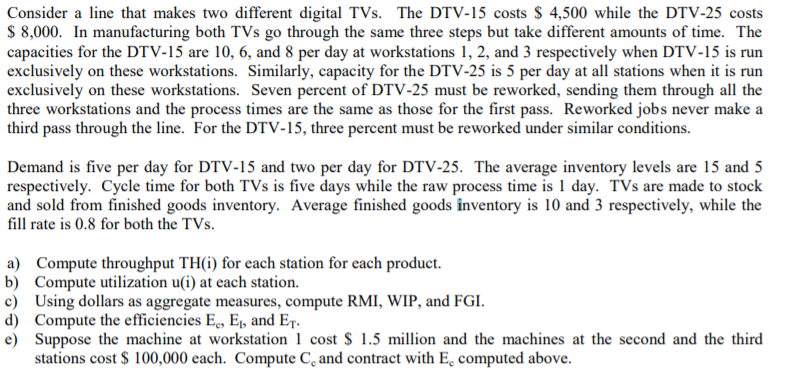

Consider a line that makes two different digital TVs. The DTV-15 costs $ 4,500 while the DTV-25 costs $ 8,000. In manufacturing both TVs go through the same three steps but take different amounts of time. The capacities for the DTV-15 are 10, 6, and 8 per day at workstations 1, 2, and 3 respectively when DTV-15 is run exclusively on these workstations. Similarly, capacity for the DTV-25 is 5 per day at all stations when it is run exclusively on these workstations. Seven percent of DTV-25 must be reworked, sending them through all the three workstations and the process times are the same as those for the first pass. Reworked jobs never make a third pass through the line. For the DTV-15, three percent must be reworked under similar conditions. Demand is five per day for DTV-15 and two per day for DTV-25. The average inventory levels are 15 and 5 respectively. Cycle time for both TVs is five days while the raw process time is 1 day. TVs are made to stock and sold from finished goods inventory. Average finished goods inventory is 10 and 3 respectively, while the fill rate is 0.8 for both the TVs. a) Compute throughput TH(i) for each station for each product. b) Compute utilization u(i) at each station. c) Using dollars as aggregate measures, compute RMI, WIP, and FGI. d) Compute the efficiencies EC, E, and Er. e) Suppose the machine at workstation 1 cost $ 1.5 million and the machines at the second and the third stations cost $ 100,000 each. Compute and contract with E. computed above. Consider a line that makes two different digital TVs. The DTV-15 costs $ 4,500 while the DTV-25 costs $ 8,000. In manufacturing both TVs go through the same three steps but take different amounts of time. The capacities for the DTV-15 are 10, 6, and 8 per day at workstations 1, 2, and 3 respectively when DTV-15 is run exclusively on these workstations. Similarly, capacity for the DTV-25 is 5 per day at all stations when it is run exclusively on these workstations. Seven percent of DTV-25 must be reworked, sending them through all the three workstations and the process times are the same as those for the first pass. Reworked jobs never make a third pass through the line. For the DTV-15, three percent must be reworked under similar conditions. Demand is five per day for DTV-15 and two per day for DTV-25. The average inventory levels are 15 and 5 respectively. Cycle time for both TVs is five days while the raw process time is 1 day. TVs are made to stock and sold from finished goods inventory. Average finished goods inventory is 10 and 3 respectively, while the fill rate is 0.8 for both the TVs. a) Compute throughput TH(i) for each station for each product. b) Compute utilization u(i) at each station. c) Using dollars as aggregate measures, compute RMI, WIP, and FGI. d) Compute the efficiencies EC, E, and Er. e) Suppose the machine at workstation 1 cost $ 1.5 million and the machines at the second and the third stations cost $ 100,000 each. Compute and contract with E. computed above

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts