Question: Please answer question 14-20 thoroughly, elaborate and put question in answer HR IN ACTION CASE INCIDENT 2 Carter Cleaning Company Motivating Safe Behavior CHAPTER 14

Please answer question 14-20 thoroughly, elaborate and put question in answer

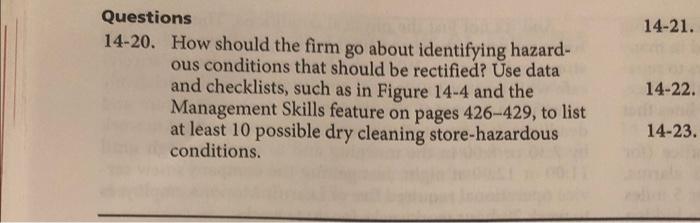

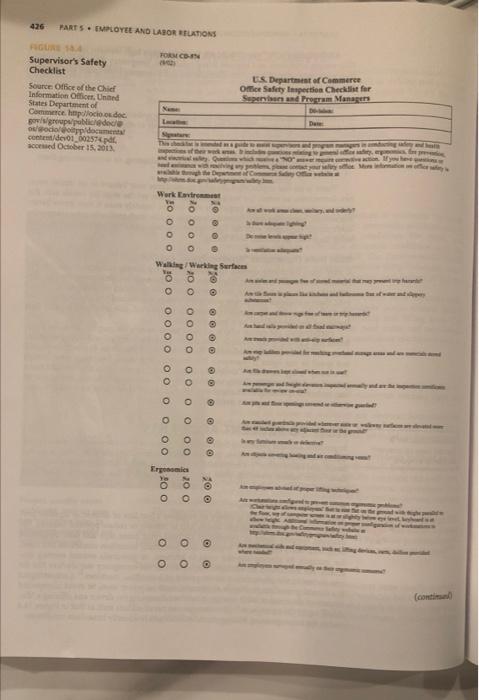

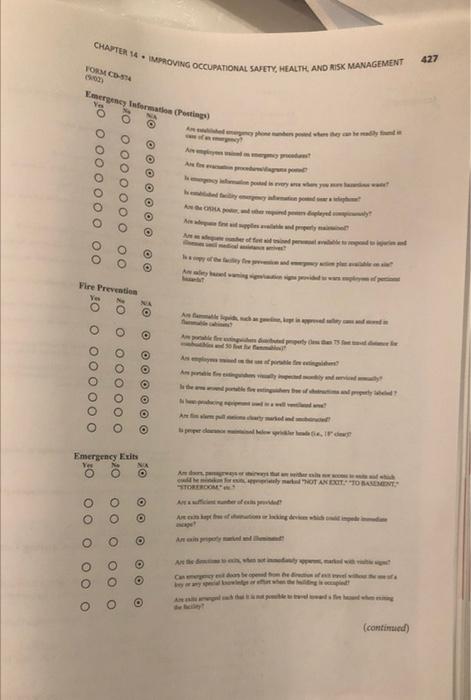

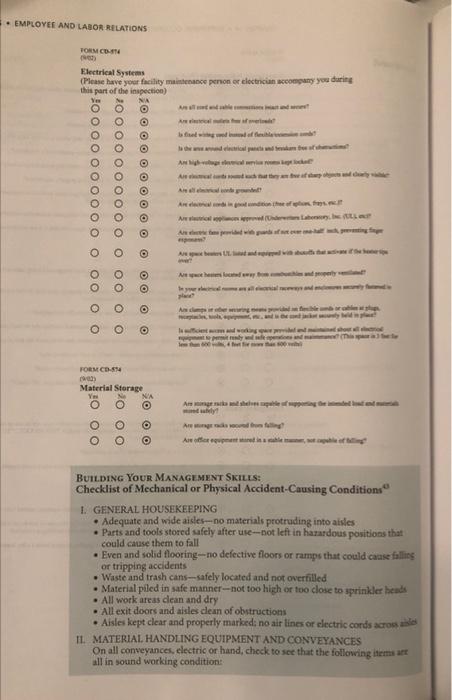

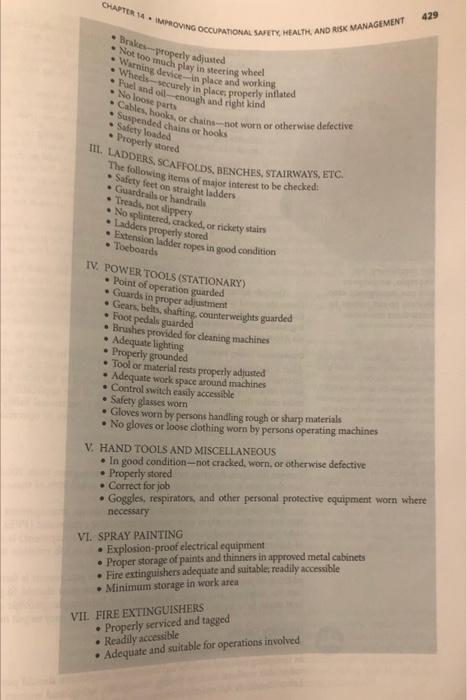

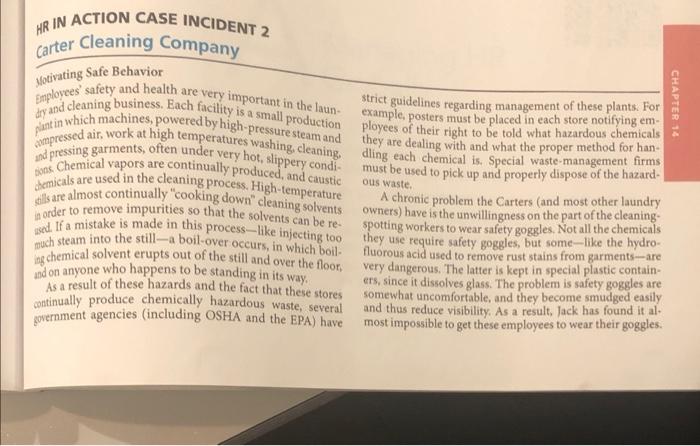

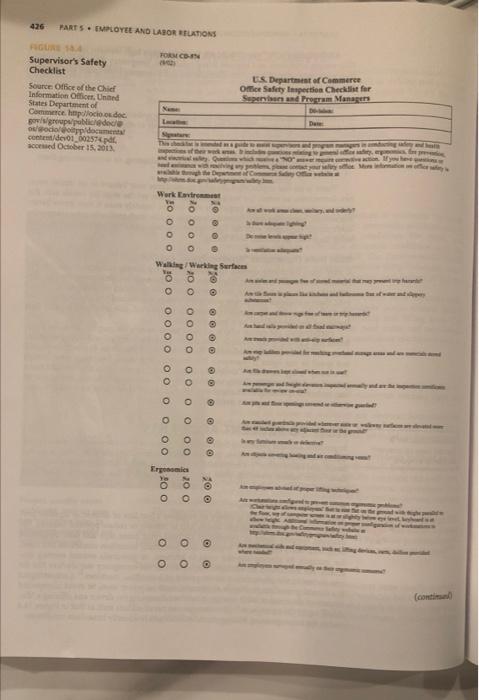

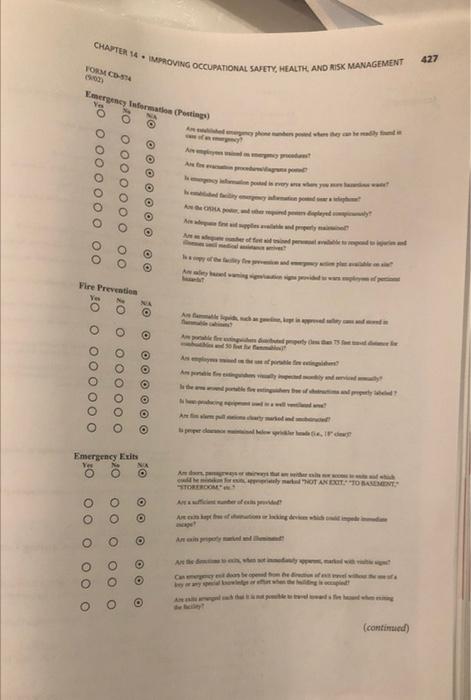

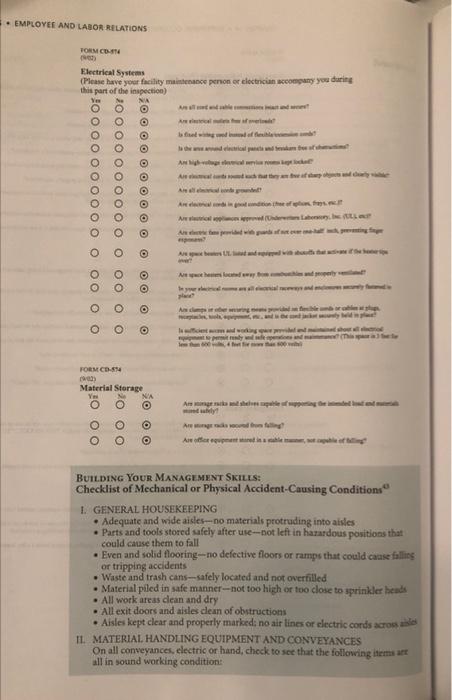

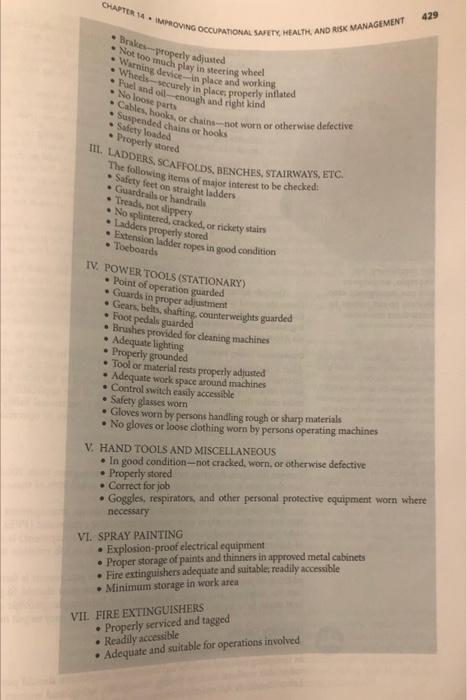

HR IN ACTION CASE INCIDENT 2 Carter Cleaning Company Motivating Safe Behavior CHAPTER 14 Employees' safety and health are very important in the laun dry and cleaning business. Each facility is a small production compressed air work at high temperatures washing, cleaning, plant in which machines, powered by high-pressure steam and and pressing garments, often under very hot, slippery condi- as Chemical vapors are continually produced, and caustic chemicals are used in the cleaning process. High-temperature soills are almost continually "cooking down" cleaning solvents in order to remove impurities so that the solvents can be re- much steam into the still a boil-over occurs, in which boil. used. If a mistake is made in this process-like injecting too ing chemical solvent erupts out of the still and over the floor, and on anyone who happens to be standing in its way. As a result of these hazards and the fact that these stores continually produce chemically hazardous waste, several government agencies (including OSHA and the EPA) have strict guidelines regarding management of these plants. For example, posters must be placed in each store notifying em- ployees of their right to be told what hazardous chemicals they are dealing with and what the proper method for han- dling each chemical is. Special waste management firms must be used to pick up and properly dispose of the hazard- ous waste. A chronic problem the Carters (and most other laundry owners) have is the unwillingness on the part of the cleaning. spotting workers to wear safety goggles. Not all the chemicals they use require safety goggles, but some-like the hydro- fluorous acid used to remove rust stains from garments-are very dangerous. The latter is kept in special plastic contain- ers, since it dissolves glass. The problem is safety goggles are somewhat uncomfortable, and they become smudged easily and thus reduce visibility. As a result, Jack has found it al- most impossible to get these employees to wear their goggles. 14-21. Questions 14-20. How should the firm go about identifying hazard- ous conditions that should be rectified? Use data and checklists, such as in Figure 14-4 and the Management skills feature on pages 426-429, to list at least 10 possible dry cleaning store-hazardous conditions. 14-22. 14-23. 426 PART 5 EMPLOYEE AND LABORATIONS FORCON tegy FIGURE SA Supervisor's Safety Checklist Source: Office of the Child Information Officer United States Department of Commerce plocio o doc. go/group.publiceede ou/ociolo documents code 01 00257 ced October 15, 2013 US Department of Commerce Ofic Safety Inspection Checklist for Super and Program Managers trali Qadivada ht the best incom halin see is idention in der Work Eat Wang Working Surface o o o oid oo o o oo oo oo o ot; o oo ota 0 0 0 0 0 : o o o or oo oo oo o o oo 0 Ergo (continuel CHAJTER 14 PROVING OCCUPATIONAL SAFETY, HEALTH AND RISK MANAGEMENT 427 Emergency Information (Puting) Yes 0 0 0 0 0 0 0 0 1 0 0 0 0 0 0 0 0 0 0 nd Fire Prevention Atelif 07 0 0 0 0 0 0 0 0 ella - wall, Irder Emergency Exits NA 8 8 hot Axt Tours TORRONE 0 m in 00 An einety rella A lis dire in he dent (continued) EMPLOYEE AND LABOR RELATIONS TORMCD-1 NO) Electrical Systems (Please have your facility maintenance person or clectric company you during this part of the inspection) NA ? bewolf to oooooooooooooo 10 OOOOOOOOOOO Amirah At Al OOO wy And o set Pin w FORM CDS Material Storage NA oo O. O O Org ttatal- ly O O BUILDING YOUR MANAGEMENT SKILLS: Checklist of Mechanical or Physical Accident-Causing Conditions 1. GENERAL HOUSEKEEPING Adequate and wide aislesno materials protruding into aisles Parts and tools stored safely after use--not left in hatardous positions that could cause them to fall Even and solid flooring-no defective floors or ramps that could cause falling or tripping accidents Waste and trash cans-safely located and not overfilled Material piled in safe manner --not too high or too close to sprinkler heads All work areas clean and dry All exit doors and aisles clean of obstructions Aisles kept clear and properly marked: no airlines or electric cords acrosse IL MATERIAL HANDLING EQUIPMENT AND CONVEYANCES On all conveyances, electric or hand, check to see that the following terms at all in sound working condition: CHAPTER 14 WPROVING OCCUPATIONAL SAFETY HEALTH AND RISK MANAGEMENT 429 Brakes-properly adjusted Not too much play in steering wheel Warning device in place and working Wheels-securely in places properly inflated Puel and oil cough and right kind Cables, hook, or chainnot worn or otherwise defective No loose parts Suspended chains or looks Safety loaded Properly stored III. LADDERS, SCAFFOLDS, BENCHES, STAIRWAYS, ETC. The following items of major interest to be checked: Extension ladder ropes in good condition Safety feet on straight ladders Guardrails or handrails Treads, not slippery No splintered, cracked or ridety stairs Ladders properly stored Toeboards IV. POWER TOOLS (STATIONARY) Point of operation guarded Guards in proper adjustment Gears, belts, shafting counterweights guarded Foot pedals guarded Brushes provided for cleaning machines Adequate lighting . . . Properly grounded Tool or material rests properly adjusted Adequate work space around machines Control switch easily accessible Safety glasses wom Gloves worn by persons handling rough or sharp materials No gloves or loose diothing worn by persons operating machines V. HAND TOOLS AND MISCELLANEOUS In good condition--not cracked, worn, or otherwise defective Properly stored Correct for job Goggles, respirators, and other personal protective equipment worn where necessary VI. SPRAY PAINTING Explosion-proof electrical equipment Proper storage of paints and thinners in approved metal cabinets Fire extinguishers adequate and suitable: readily accessible Minimum storage in work area VIL FIRE EXTINGUISHERS Properly serviced and tagged Readily accessible Adequate and suitable for operations involved

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock