Question: PLEASE ANSWER QUESTIONS 1 & 2 Cementing Its Position TEXAS LEHIGH RTLAND CEMEX NEVADA Eagle Materials Eagle Materials is the 8th largest producer of construction

PLEASE ANSWER QUESTIONS 1 & 2

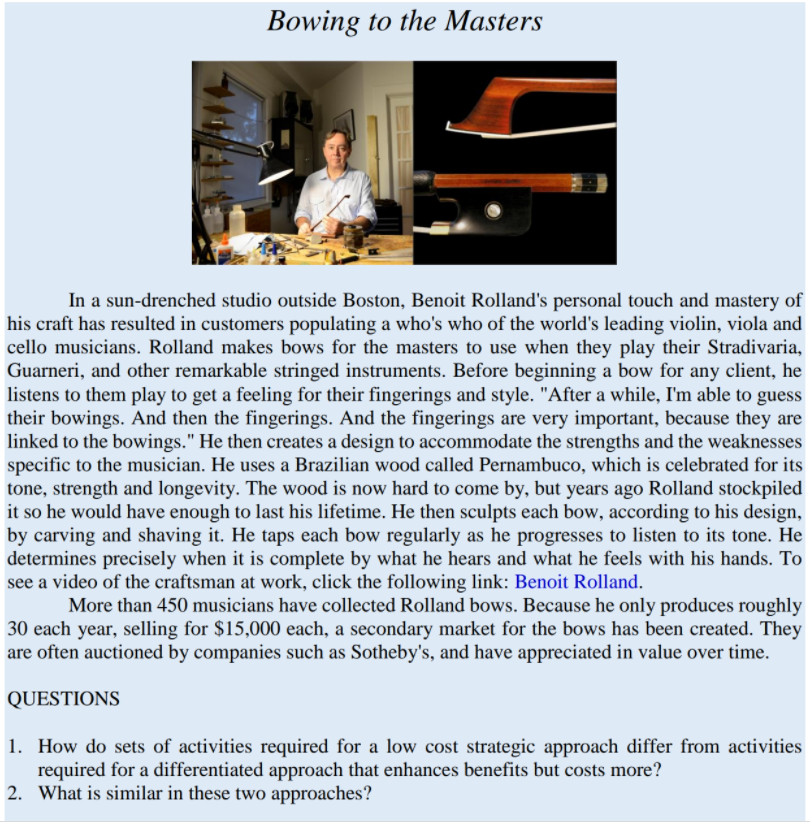

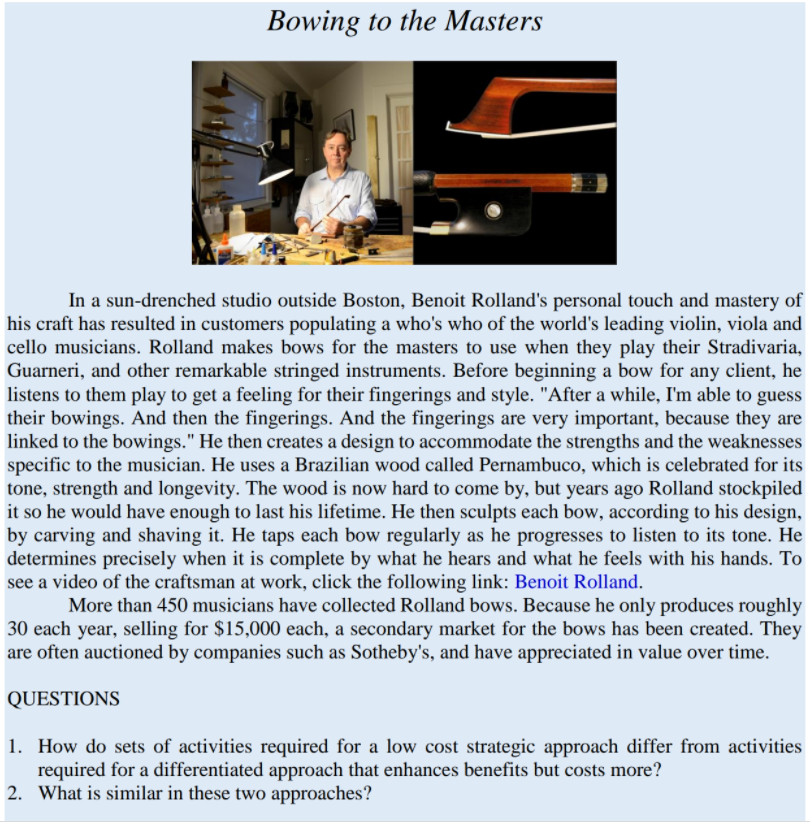

Cementing Its Position TEXAS LEHIGH RTLAND CEMEX NEVADA Eagle Materials Eagle Materials is the 8th largest producer of construction cement in the U.S., competing against larger multinational public corporations. In this commodity business, where all cement pretty much looks and acts the same, having a cost structure to ensure competitive pricing is a key to success. Eagle is the low cost producer. They have gained this position by carefully managing all aspects of their operations, so they have cost advantages on multiple dimensions: raw materials, natural gas usage, production and construction waste, administrative overhead, inbound and outbound transportation expense. Because their operations use less energy and produce less waste, they are equally aligned with environmental sustainability goals. Since they charge competitive prices but their delivered cost to the market is lower, Eagle earns superior returns. In 2019 they reported an industry-leading 33% EBITDA. Their 5-year pretax margin is almost double the nearest competitor, and their 5-year ROE of 14.7% exceeds all companies in the industry. Five-Year Pretax Margin %, 2015-2019 Five-Year ROE %, 2015-2019 25 15 20 10 15 10 5 5 Eagle Marietta Vulcan Continental USG Eagle Continental USG Marietta Vulcan Bowing to the Masters In a sun-drenched studio outside Boston, Benoit Rolland's personal touch and mastery of his craft has resulted in customers populating a who's who of the world's leading violin, viola and cello musicians. Rolland makes bows for the masters to use when they play their Stradivaria, Guarneri, and other remarkable stringed instruments. Before beginning a bow for any client, he listens to them play to get a feeling for their fingerings and style. "After a while, I'm able to guess their bowings. And then the fingerings. And the fingerings are very important, because they are linked to the bowings." He then creates a design to accommodate the strengths and the weaknesses specific to the musician. He uses a Brazilian wood called Pernambuco, which is celebrated for its tone, strength and longevity. The wood is now hard to come by, but years ago Rolland stockpiled it so he would have enough to last his lifetime. He then sculpts each bow, according to his design, by carving and shaving it. He taps each bow regularly as he progresses to listen to its tone. He determines precisely when it is complete by what he hears and what he feels with his hands. To see a video of the craftsman at work, click the following link: Benoit Rolland. More than 450 musicians have collected Rolland bows. Because he only produces roughly 30 each year, selling for $15,000 each, a secondary market for the bows has been created. They are often auctioned by companies such as Sotheby's, and have appreciated in value over time. QUESTIONS 1. How do sets of activities required for a low cost strategic approach differ from activities required for a differentiated approach that enhances benefits but costs more? 2. What is similar in these two approaches