Question: please answer the following 3.19 When would you recommend a fixed position layout? 5. (20 points) 6.13 In an assembly plant, material handling between departments

please answer the following

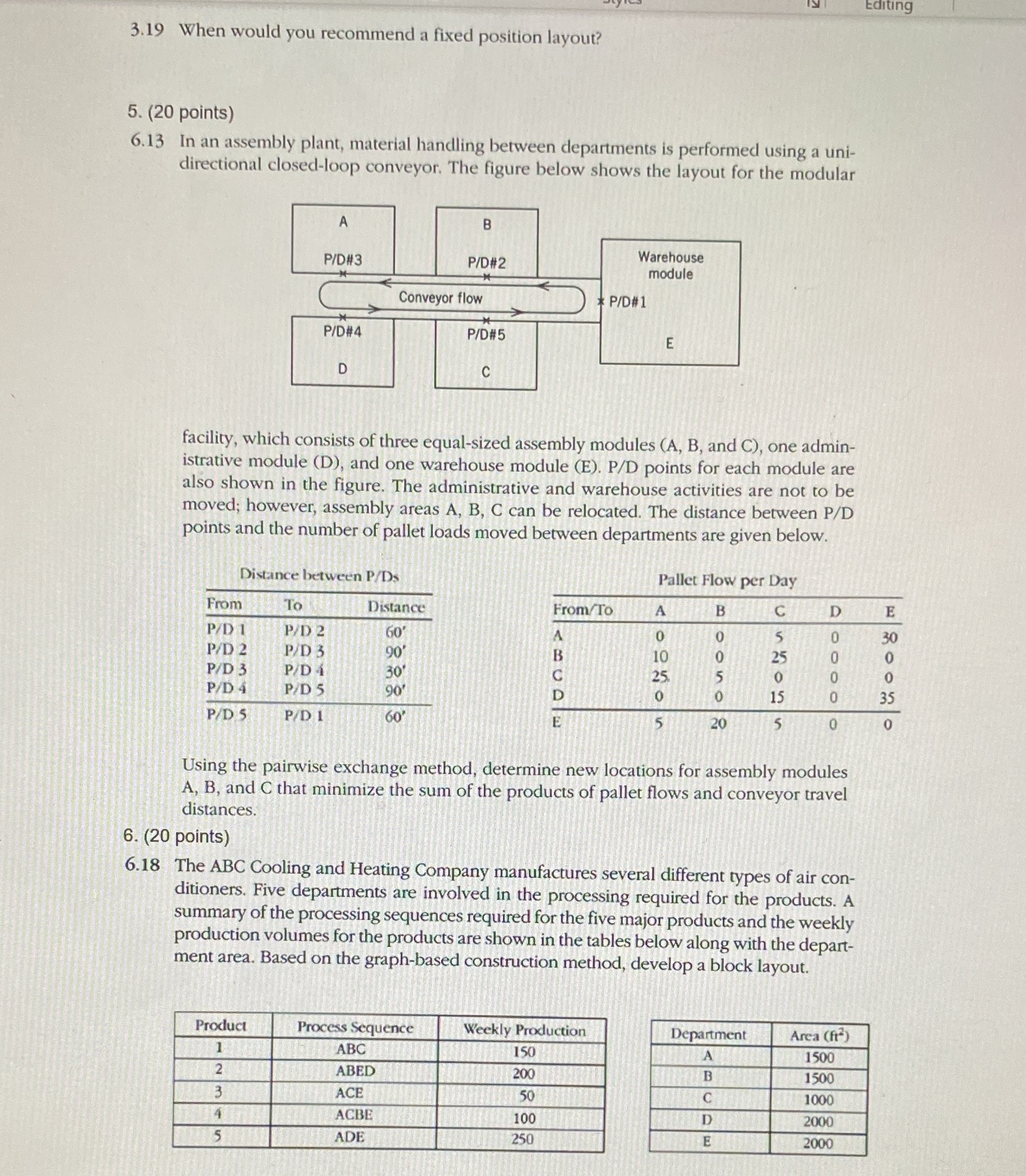

3.19 When would you recommend a fixed position layout? 5. (20 points) 6.13 In an assembly plant, material handling between departments is performed using a uni- directional closed-loop conveyor. The figure below shows the layout for the modular B P/D#3 P/D#2 Warehouse module Conveyor flow P/D#1 P/D#4 P/D#5 E facility, which consists of three equal-sized assembly modules (A, B, and C), one admin- istrative module (D), and one warehouse module (E). P/D points for each module are also shown in the figure. The administrative and warehouse activities are not to be moved; however, assembly areas A, B, C can be relocated. The distance between P/D points and the number of pallet loads moved between departments are given below. Distance between P/Ds Pallet Flow per Day From To Distance From To B C D E P/D P/D 2 60' 30 P/D 2 P/D 3 90' 10 P/D 3 30' 25 P/D 4 P/D 5 90' P/DS P/DI 60' 20 Using the pairwise exchange method, determine new locations for assembly modules A, B, and C that minimize the sum of the products of pallet flows and conveyor travel distances. 6. (20 points) 6.18 The ABC Cooling and Heating Company manufactures several different types of air con- ditioners. Five departments are involved in the processing required for the products. A summary of the processing sequences required for the five major products and the weekly production volumes for the products are shown in the tables below along with the depart- ment area. Based on the graph-based construction method, develop a block layout. Product Process Sequence Weekly Production Department Area (ft-) ABC 150 1500 2 ABED 200 1500 ACE 50 1000 ACBE 100 D 2000 ADE 250 E 2000

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts