Question: Please answer the following questions using the scenario below. Resource: Immediate & Basic Causes.pdf You were selected to investigate accidents at your company. After reviewing

Please answer the following questions using the scenario below. Resource: Immediate & Basic Causes.pdf

You were selected to investigate accidents at your company. After reviewing the evidence and interviewing different employees, you gather the following facts:

- A production employee slipped and fell on the floor while he was working in his assembly workstation

- As a result of the fall, he broke his arm

- Many machines, including the machine he was working at, are still leaking oil

- At the time of the accident, the floor was covered with many puddles of oil

- The injured employee has been in this position for more than 1 year, and has worked 13 years in the same manufacturing plant

- All the production employees have received many safety trainings during their job (it is assumed that lack of training is not an issue)

a) Select 2 immediate causes from the list and provide an explanation for each

b) Select 2 basic causes from the list for each immediate cause and provide an explanation for each

c) Select 2 basic causes and list one corrective action for each basic cause

d) Apart from completing an accident investigation, what other actions does the employer need to take?

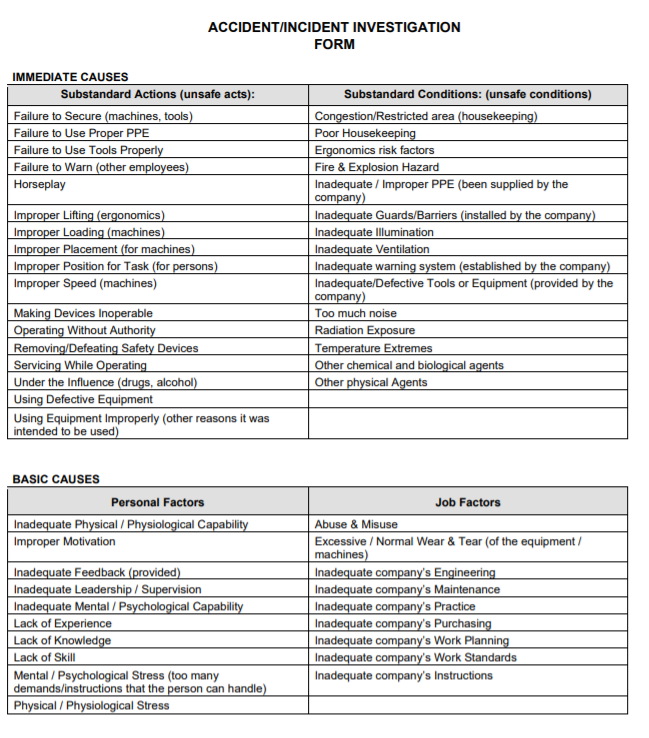

ACCIDENT/INCIDENT INVESTIGATION FORM IMMEDIATE CAUSES Substandard Actions (unsafe acts): Failure to Secure (machines, tools) Failure to Use Proper PPE Failure to Use Tools Properly Failure to Warn (other employees) Horseplay Improper Lifting (ergonomics) Improper Loading (machines) Improper Placement (for machines) Improper Position for Task (for persons) Improper Speed (machines) Substandard Conditions: (unsafe conditions) Congestion/Restricted area (housekeeping) Poor Housekeeping Ergonomics risk factors Fire & Explosion Hazard Inadequate / Improper PPE (been supplied by the company) Inadequate Guards/Barriers (installed by the company) Inadequate Illumination Inadequate Ventilation Inadequate warning system (established by the company) Inadequate/Defective Tools or Equipment (provided by the company) Too much noise Radiation Exposure Temperature Extremes Other chemical and biological agents Other physical Agents Making Devices Inoperable Operating Without Authority Removing/Defeating Safety Devices Servicing While Operating Under the Influence (drugs, alcohol) Using Defective Equipment Using Equipment Improperly (other reasons it was intended to be used) BASIC CAUSES Personal Factors Inadequate Physical / Physiological Capability Improper Motivation Inadequate Feedback (provided) Inadequate Leadership / Supervision Inadequate Mental / Psychological Capability Lack of Experience Lack of Knowledge Lack of Skill Mental / Psychological Stress (too many demands/instructions that the person can handle) Physical / Physiological Stress Job Factors Abuse & Misuse Excessive / Normal Wear & Tear of the equipment / machines) Inadequate company's Engineering Inadequate company's Maintenance Inadequate company's Practice Inadequate company's Purchasing Inadequate company's Work Planning Inadequate company's Work Standards Inadequate company's InstructionsStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts