Question: please complete the excel. Fill UP ALL THE SPOT please also provide a formula as well. CASE STUDY Designing the Production Network at CoolWipes Matt

please complete the excel. Fill UP ALL THE SPOT please also provide a formula as well.

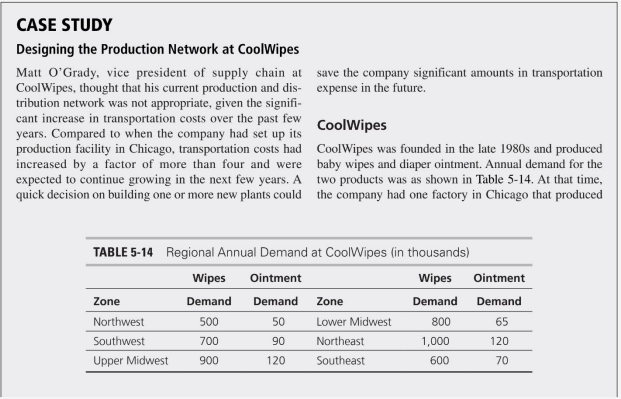

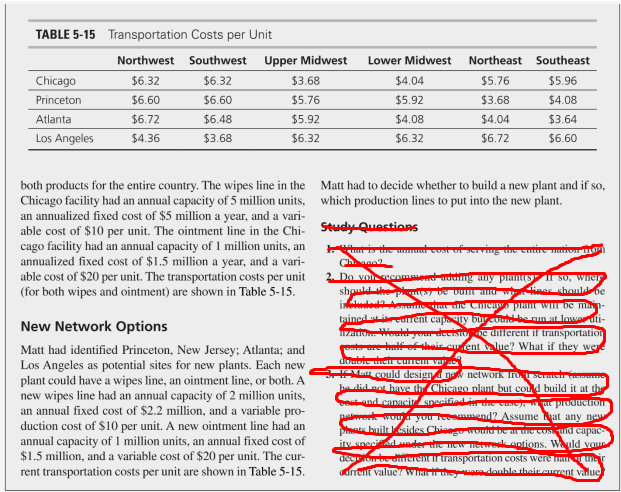

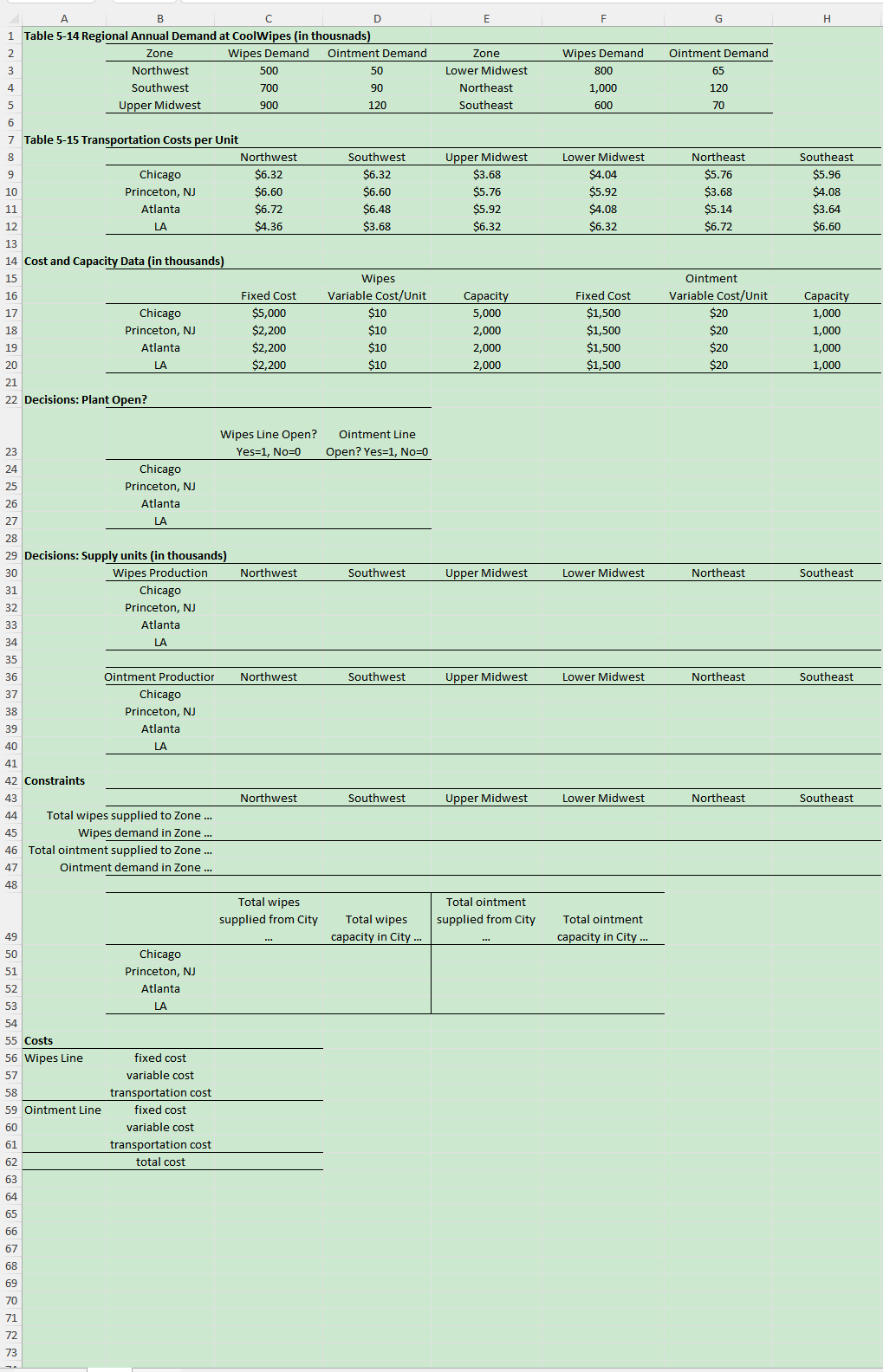

CASE STUDY Designing the Production Network at CoolWipes Matt O'Grady, vice president of supply chain at save the company significant amounts in transportation CoolWipes, thought that his current production and dis- expense in the future. tribution network was not appropriate, given the significant increase in transportation costs over the past few years. Compared to when the company had set up its CoolWipes production facility in Chicago, transportation costs had CoolWipes was founded in the late 1980s and produced increased by a factor of more than four and were baby wipes and diaper ointment. Annual demand for the expected to continue growing in the next few years. A two products was as shown in Table 5-14. At that time, quick decision on building one or more new plants could the company had one factory in Chicago that produced both products for the entire country. The wipes line in the Chicago facility had an annual capacity of 5 million units, an annualized fixed cost of $5 million a year, and a variable cost of $10 per unit. The ointment line in the Chicago facility had an annual capacity of 1 million units, an annualized fixed cost of $1.5 million a year, and a variable cost of $20 per unit. The transportation costs per unit (for both wipes and ointment) are shown in Table 5-15. New Network Options Matt had identified Princeton, New Jersey; Atlanta; and Los Angeles as potential sites for new plants. Each new plant could have a wipes line, an ointment line, or both. A new wipes line had an annual capacity of 2 million units, an annual fixed cost of $2.2 million, and a variable production cost of $10 per unit. A new ointment line had an annual capacity of 1 million units, an annual fixed cost of $1.5 million, and a variable cost of $20 per unit. The current transportation costs per unit are shown in Table 5-15. Decisions: Plant Open? Decisions: Supply units (in thousands) Constraints Total wipes supplied to Zone ... Wipes demand in Zone ... Total ointment supplied to Zone ... Ointment demand in Zone ... Costs Wipes Line fixed cost variable cost transportation cost Ointment Line fixed cost variable cost transportation cost total cost

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts