Question: PLEASE DO STUDY TASK 2 WE HAVE LIMITED TIME. PLANNING AND SCHEDULING IN THE FCC COMPANY FCC Company produces a line of pots and pans

PLEASE DO STUDY TASK 2 WE HAVE LIMITED TIME.

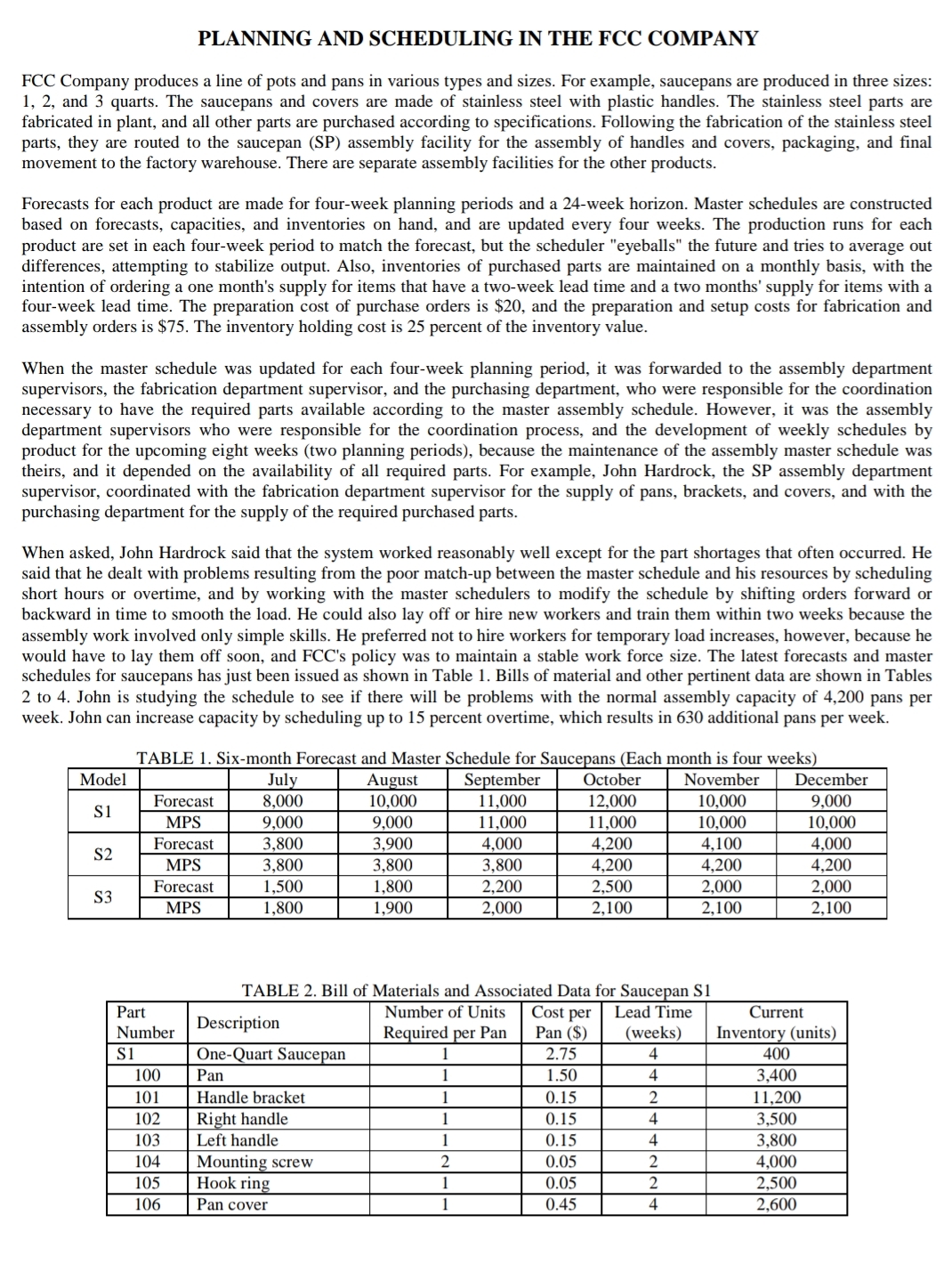

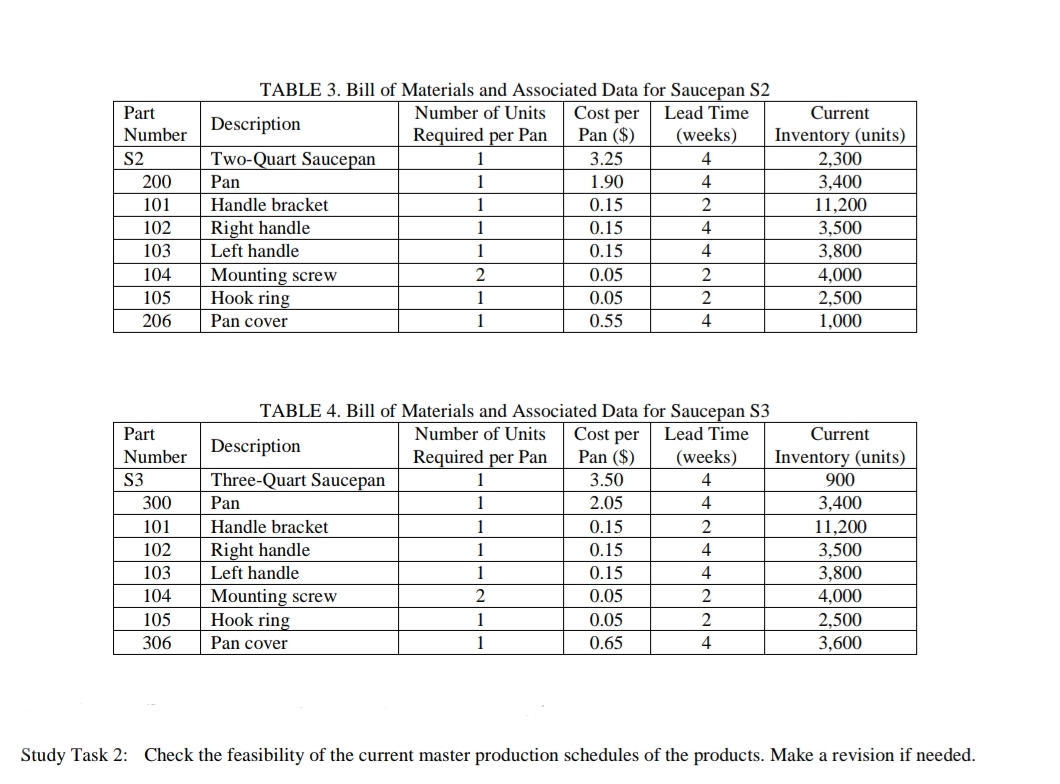

PLANNING AND SCHEDULING IN THE FCC COMPANY FCC Company produces a line of pots and pans in various types and sizes. For example, saucepans are produced in three sizes: 1, 2, and 3 quarts. The saucepans and covers are made of stainless steel with plastic handles. The stainless steel parts are fabricated in plant, and all other parts are purchased according to specifications. Following the fabrication of the stainless steel parts, they are routed to the saucepan (SP) assembly facility for the assembly of handles and covers, packaging, and final movement to the factory warehouse. There are separate assembly facilities for the other products. Forecasts for each product are made for four-week planning periods and a 24-week horizon. Master schedules are constructed based on forecasts, capacities, and inventories on hand, and are updated every four weeks. The production runs for each product are set in each four-week period to match the forecast, but the scheduler "eyeballs" the future and tries to average out differences, attempting to stabilize output. Also, inventories of purchased parts are maintained on a monthly basis, with the intention of ordering a one month's supply for items that have a two-week lead time and a two months' supply for items with a four-week lead time. The preparation cost of purchase orders is $20, and the preparation and setup costs for fabrication and assembly orders is $75. The inventory holding cost is 25 percent of the inventory value. When the master schedule was updated for each four-week planning period, it was forwarded to the assembly department supervisors, the fabrication department supervisor, and the purchasing department, who were responsible for the coordination necessary to have the required parts available according to the master assembly schedule. However, it was the assembly department supervisors who were responsible for the coordination process, and the development of weekly schedules by product for the upcoming eight weeks (two planning periods), because the maintenance of the assembly master schedule was theirs, and it depended on the availability of all required parts. For example, John Hardrock, the SP assembly department supervisor, coordinated with the fabrication department supervisor for the supply of pans, brackets, and covers, and with the purchasing department for the supply of the required purchased parts. When asked, John Hardrock said that the system worked reasonably well except for the part shortages that often occurred. He said that he dealt with problems resulting from the poor match-up between the master schedule and his resources by scheduling short hours or overtime, and by working with the master schedulers to modify the schedule by shifting orders forward or backward in time to smooth the load. He could also lay off or hire new workers and train them within two weeks because the assembly work involved only simple skills. He preferred not to hire workers for temporary load increases, however, because he would have to lay them off soon, and FCC's policy was to maintain a stable work force size. The latest forecasts and master schedules for saucepans has just been issued as shown in Table 1. Bills of material and other pertinent data are shown in Tables 2 to 4 . John is studying the schedule to see if there will be problems with the normal assembly capacity of 4,200 pans per week. John can increase capacity by scheduling up to 15 percent overtime, which results in 630 additional pans per week. TABLE 3. Bill of Materials and Associated Data for Saucevan S2 TABIE 4. Bill of Materials and Associated Data for Saucenan S3 Study Task 2: Check the feasibility of the current master production schedules of the products. Make a revision if needed

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts