Question: Please fully answer, will upvote if done correctly. SharkNinja is between two suppliers for motors used in production of its vacuum cleaners. Annual holding cost

Please fully answer, will upvote if done correctly.

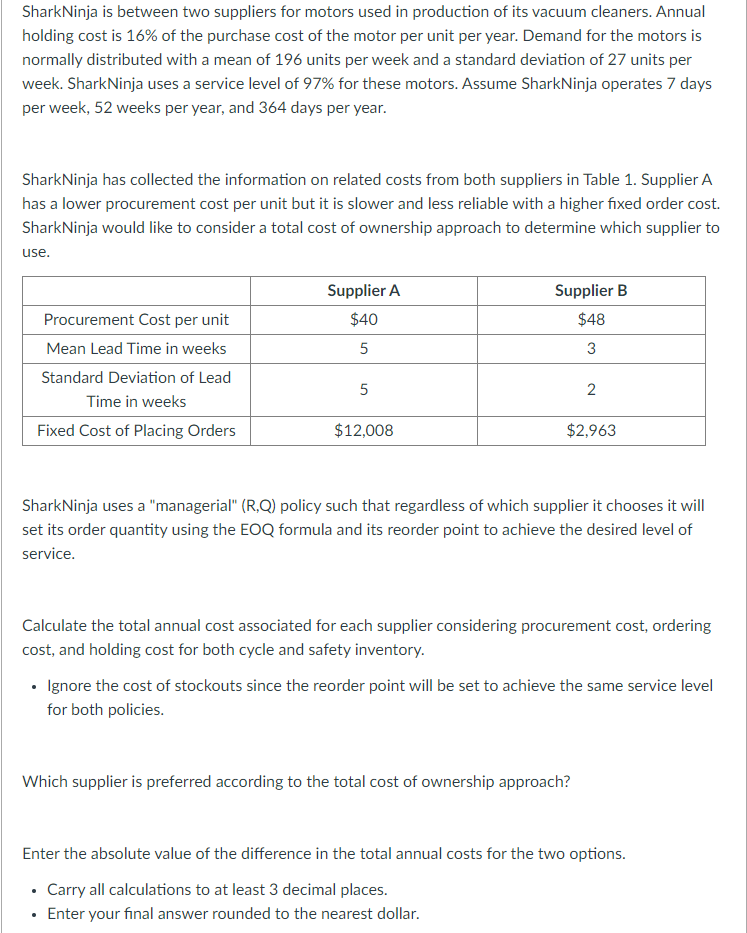

SharkNinja is between two suppliers for motors used in production of its vacuum cleaners. Annual holding cost is 16% of the purchase cost of the motor per unit per year. Demand for the motors is normally distributed with a mean of 196 units per week and a standard deviation of 27 units per week. SharkNinja uses a service level of 97% for these motors. Assume SharkNinja operates 7 days per week, 52 weeks per year, and 364 days per year. SharkNinja has collected the information on related costs from both suppliers in Table 1. Supplier A has a lower procurement cost per unit but it is slower and less reliable with a higher fixed order cost. SharkNinja would like to consider a total cost of ownership approach to determine which supplier to use. SharkNinja uses a "managerial" (R,Q) policy such that regardless of which supplier it chooses it will set its order quantity using the EOQ formula and its reorder point to achieve the desired level of service. Calculate the total annual cost associated for each supplier considering procurement cost, ordering cost, and holding cost for both cycle and safety inventory. - Ignore the cost of stockouts since the reorder point will be set to achieve the same service level for both policies. Which supplier is preferred according to the total cost of ownership approach? Enter the absolute value of the difference in the total annual costs for the two options. - Carry all calculations to at least 3 decimal places. - Enter your final answer rounded to the nearest dollar

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts