Question: Please help me answer P3-6 :(. Also, I'm not sure with my answers in P3-3, please help me :(( of Required: Using the ABC system,

Please help me answer P3-6 :(. Also, I'm not sure with my answers in P3-3, please help me :((

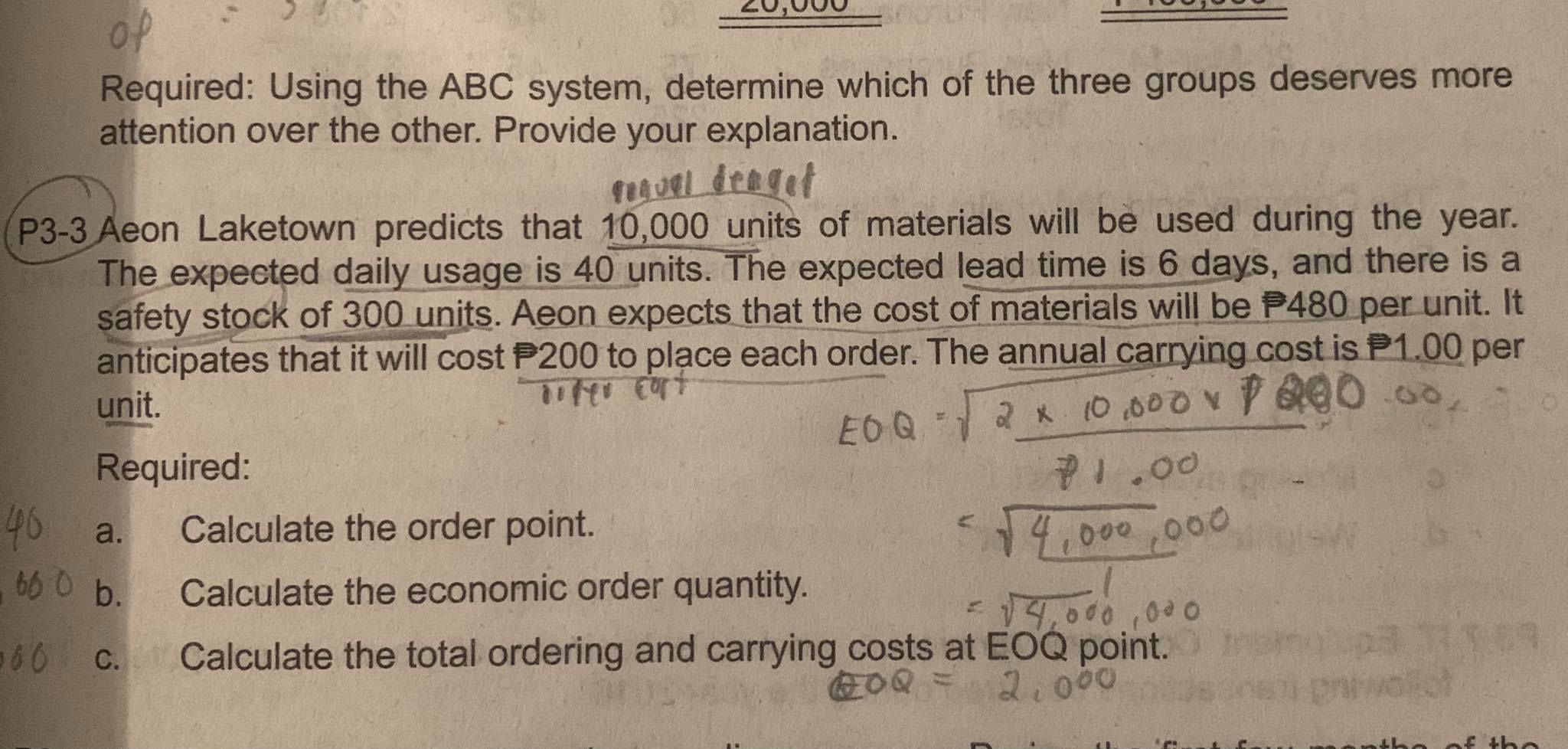

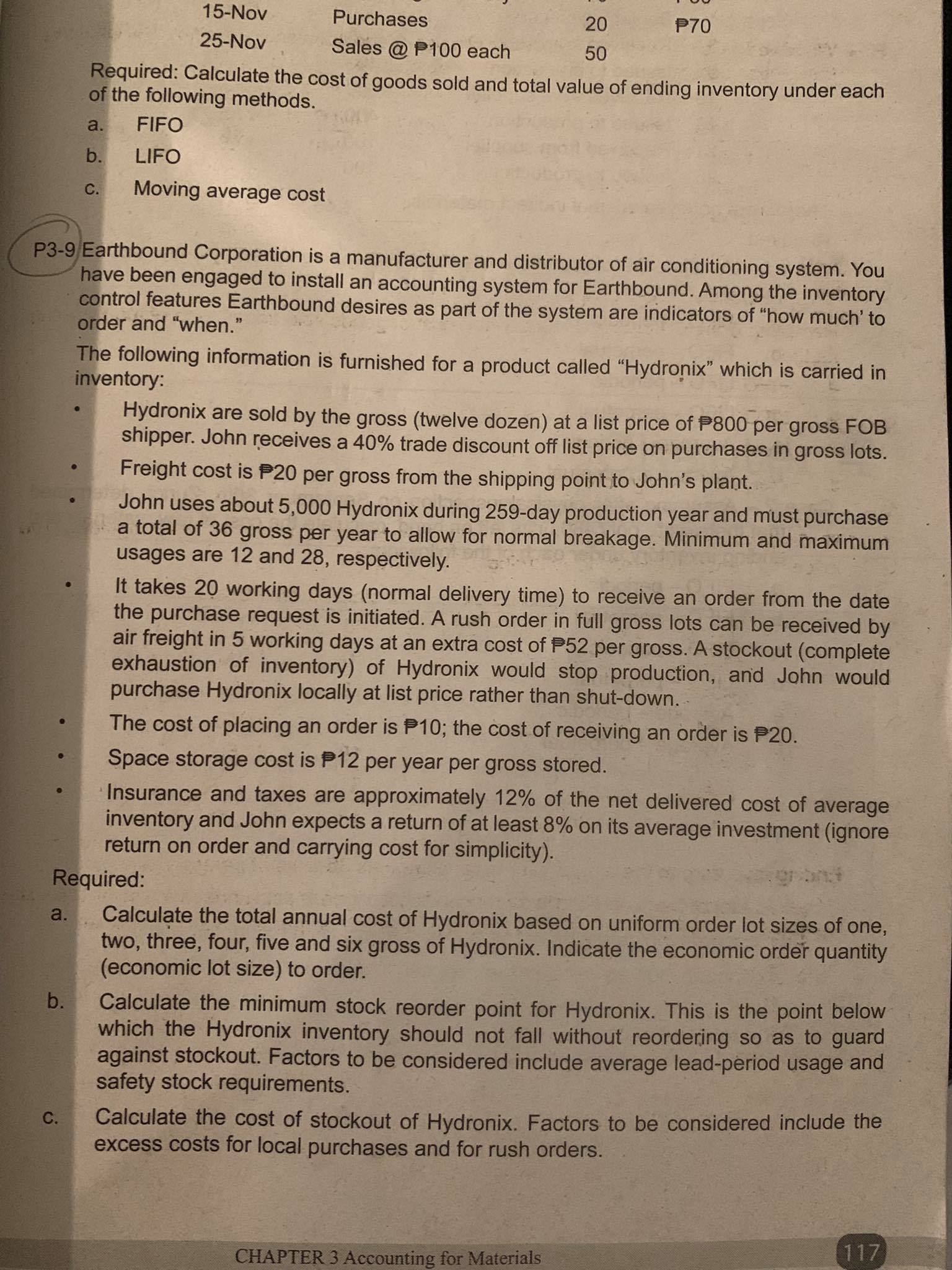

of Required: Using the ABC system, determine which of the three groups deserves more attention over the other. Provide your explanation. sequel denget P3-3 Aeon Laketown predicts that 10,000 units of materials will be used during the year. The expected daily usage is 40 units. The expected lead time is 6 days, and there is a safety stock of 300 units. Aeon expects that the cost of materials will be P480 per unit. It anticipates that it will cost P200 to place each order. The annual carrying cost is P1.00 per unit. EO Q 2 x 10,000 1280 601 20 Required: 81.00 40 a. Calculate the order point. 514, 000,000 60 0 b. Calculate the economic order quantity. 14, 000 , 00 0 60 C. Calculate the total ordering and carrying costs at EOQ point. 400 - 21 00015-Nov Purchases 20 P70 25-Nov Sales @ P100 each 50 Required: Calculate the cost of goods sold and total value of ending inventory under each of the following methods. a. FIFO b. LIFO C. Moving average cost P3-9 Earthbound Corporation is a manufacturer and distributor of air conditioning system. You have been engaged to install an accounting system for Earthbound. Among the inventory control features Earthbound desires as part of the system are indicators of "how much' to order and "when." The following information is furnished for a product called "Hydronix" which is carried in inventory: Hydronix are sold by the gross (twelve dozen) at a list price of P800 per gross FOB shipper. John receives a 40% trade discount off list price on purchases in gross lots. Freight cost is P20 per gross from the shipping point to John's plant. John uses about 5,000 Hydronix during 259-day production year and must purchase a total of 36 gross per year to allow for normal breakage. Minimum and maximum usages are 12 and 28, respectively. It takes 20 working days (normal delivery time) to receive an order from the date the purchase request is initiated. A rush order in full gross lots can be received by air freight in 5 working days at an extra cost of P52 per gross. A stockout (complete exhaustion of inventory) of Hydronix would stop production, and John would purchase Hydronix locally at list price rather than shut-down. The cost of placing an order is P10; the cost of receiving an order is P20. Space storage cost is P12 per year per gross stored. Insurance and taxes are approximately 12% of the net delivered cost of average inventory and John expects a return of at least 8% on its average investment (ignore return on order and carrying cost for simplicity). Required: a. Calculate the total annual cost of Hydronix based on uniform order lot sizes of one, two, three, four, five and six gross of Hydronix. Indicate the economic order quantity (economic lot size) to order. b. Calculate the minimum stock reorder point for Hydronix. This is the point below which the Hydronix inventory should not fall without reordering so as to guard against stockout. Factors to be considered include average lead-period usage and safety stock requirements. C. Calculate the cost of stockout of Hydronix. Factors to be considered include the excess costs for local purchases and for rush orders. CHAPTER 3 Accounting for Materials

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts