Question: Please help with the answer for this below question Question 5 Sleep Well Inc. has a production budget of 600 beds for the current year

Please help with the answer for this below question

Question 5

Sleep Well Inc. has a production budget of 600 beds for the current year and for allocating the manufacturing overhead (i.e., indirect cost pool). Sleep Well Inc. uses the direct labour-hours for assembly and woodwork (carpenter) to allocate manufacturing overhead. Koren and Jingran are not sure whether the production budget will be met and some of its consequences.

Required

a) If the quantity produced in the current year reaches the budgeted amount of 600 beds whereas in the past year the production was 500 beds, Jonathan says the per unit product cost in the current year will increase when compared to the previous year because the production has increased. Is Jonathan right or wrong in his statement and why? Use calculations for supporting your argument. (Chapter 2, 10 marks)

b) Considering Sleep Well Inc. uses budgeted indirect costs during the year, if the quantity produced in the current year is only 400 beds whereas the production budget for the current year is 600 beds, Jonathan says there will be an overallocation of indirect costs. Is Jonathan right or wrong in his statement? What could lead to an overallocation or underallocation of indirect costs specifically for the beds? Use calculations for supporting your argument. (Budgeted indirect costs and end-of-period adjustments, Chapter 3, 10 marks)

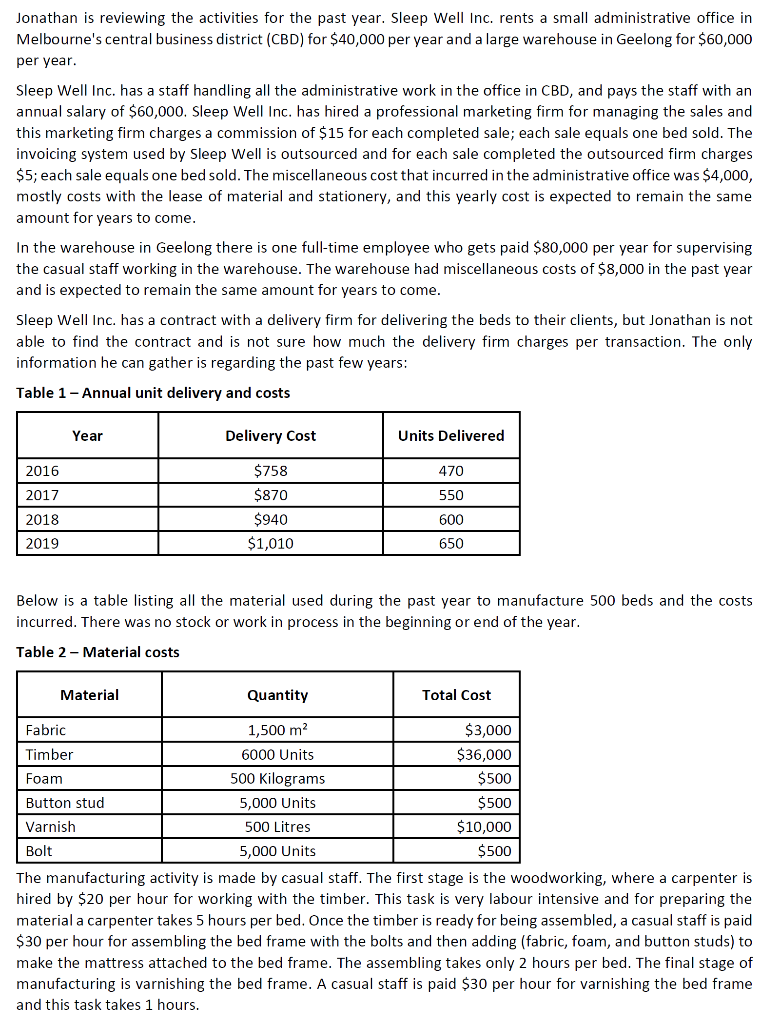

Jonathan is reviewing the activities for the past year. Sleep Well Inc. rents a small administrative office in Melbourne's central business district (CBD) for $40,000 per year and a large warehouse in Geelong for $60,000 per year. Sleep Well Inc. has a staff handling all the administrative work in the office in CBD, and pays the staff with an annual salary of $60,000. Sleep Well Inc. has hired a professional marketing firm for managing the sales and this marketing firm charges a commission of $15 for each completed sale; each sale equals one bed sold. The invoicing system used by Sleep Well is outsourced and for each sale completed the outsourced firm charges $5; each sale equals one bed sold. The miscellaneous cost that incurred in the administrative office was $4,000, mostly costs with the lease of material and stationery, and this yearly cost is expected to remain the same amount for years to come. In the warehouse in Geelong there is one full-time employee who gets paid $80,000 per year for supervising the casual staff working in the warehouse. The warehouse had miscellaneous costs of $8,000 in the past year and is expected to remain the same amount for years to come. Sleep Well Inc. has a contract with a delivery firm for delivering the beds to their clients, but Jonathan is not able to find the contract and is not sure how much the delivery firm charges per transaction. The only information he can gather is regarding the past few years: Table 1 - Annual unit delivery and costs Year Delivery Cost Units Delivered 2016 470 2017 550 $758 $870 $940 $1,010 2018 2019 600 650 Below is a table listing all the material used during the past year to manufacture 500 beds and the costs incurred. There was no stock or work in process in the beginning end of the year. Table 2 - Material costs Material Quantity Total Cost Fabric 1,500 m2 $3,000 Timber 6000 Units $36,000 Foam 500 Kilograms $500 Button stud 5,000 Units $500 Varnish 500 Litres $10,000 Bolt 5,000 Units $500 The manufacturing activity is made by casual staff. The first stage is the woodworking, where a carpenter is hired by $20 per hour for working with the timber. This task is very labour intensive and for preparing the material a carpenter takes 5 hours per bed. Once the timber is ready for being assembled, a casual staff is paid $30 per hour for assembling the bed frame with the bolts and then adding (fabric, foam, and button studs) to make the mattress attached to the bed frame. The assembling takes only 2 hours per bed. The final stage of manufacturing is varnishing the bed frame. A casual staff is paid $30 per hour for varnishing the bed frame and this task takes 1 hours

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts