Question: Please provide the network flow model for this question. No need to solve it, just a network model. 125 160 AutoSupply Corporation is a global

Please provide the network flow model for this question. No need to solve it, just a network model.

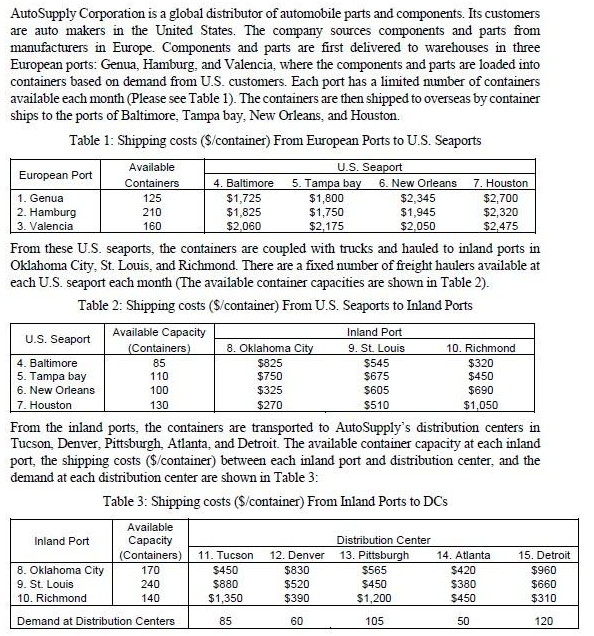

125 160 AutoSupply Corporation is a global distributor of automobile parts and components. Its customers are auto makers in the United States. The company sources components and parts from manufacturers in Europe. Components and parts are first delivered to warehouses in three European ports: Genua, Hamburg, and Valencia, where the components and parts are loaded into containers based on demand from U.S. customers. Each port has a limited number of containers available each month (Please see Table 1). The containers are then shipped to overseas by container ships to the ports of Baltimore, Tampa bay, New Orleans, and Houston. Table 1: Shipping costs (S/container) From European Ports to U.S. Seaports Available U.S. Seaport European Port Containers 4. Baltimore 5. Tampa bay 6. New Orleans 7. Houston 1. Genua $1,725 $1,800 $2,345 $2,700 2. Hamburg 210 $1,825 $1,750 $1,945 $2,320 3. Valencia $2,060 $2,175 $2,050 $2.475 From these U.S. seaports, the containers are coupled with trucks and hauled to inland ports in Oklahoma City, St. Louis, and Richmond. There are a fixed number of freight haulers available at each U.S. seaport each month (The available container capacities are shown in Table 2). Table 2: Shipping costs (S/container) From U.S. Seaports to Inland Ports U.S. Seaport Available Capacity Inland Port (Containers) 8. Oklahoma City 9. St. Louis 10. Richmond 4. Baltimore $825 $320 5. Tampa bay $750 $675 $450 6. New Orleans 100 $325 $605 $690 7. Houston 130 $270 $510 $1,050 From the inland ports, the containers are transported to Auto Supply's distribution centers in Tucson. Denver, Pittsburgh Atlanta, and Detroit. The available container capacity at each inland port, the shipping costs ($/container) between each inland port and distribution center, and the demand at each distribution center are shown in Table 3: Table 3: Shipping costs (S/container) From Inland Ports to DCS Available Inland Port Capacity Distribution Center (Containers) 11. Tucson 13. Pittsburgh 14. Atlanta 8. Oklahoma City 9. St. Louis 240 $880 $520 $450 $380 $660 10. Richmond $1,350 $390 $1,200 $450 $310 Demand at Distribution Centers $545 85 110 12. Denver $830 15. Detroit $960 170 $450 $565 $420 140 85 60 105 50 120Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts