Question: Please see attached for full details. A process is designed to produce 2,350 units per hour. The process has a scrap rate of 1.2% and

Please see attached for full details.

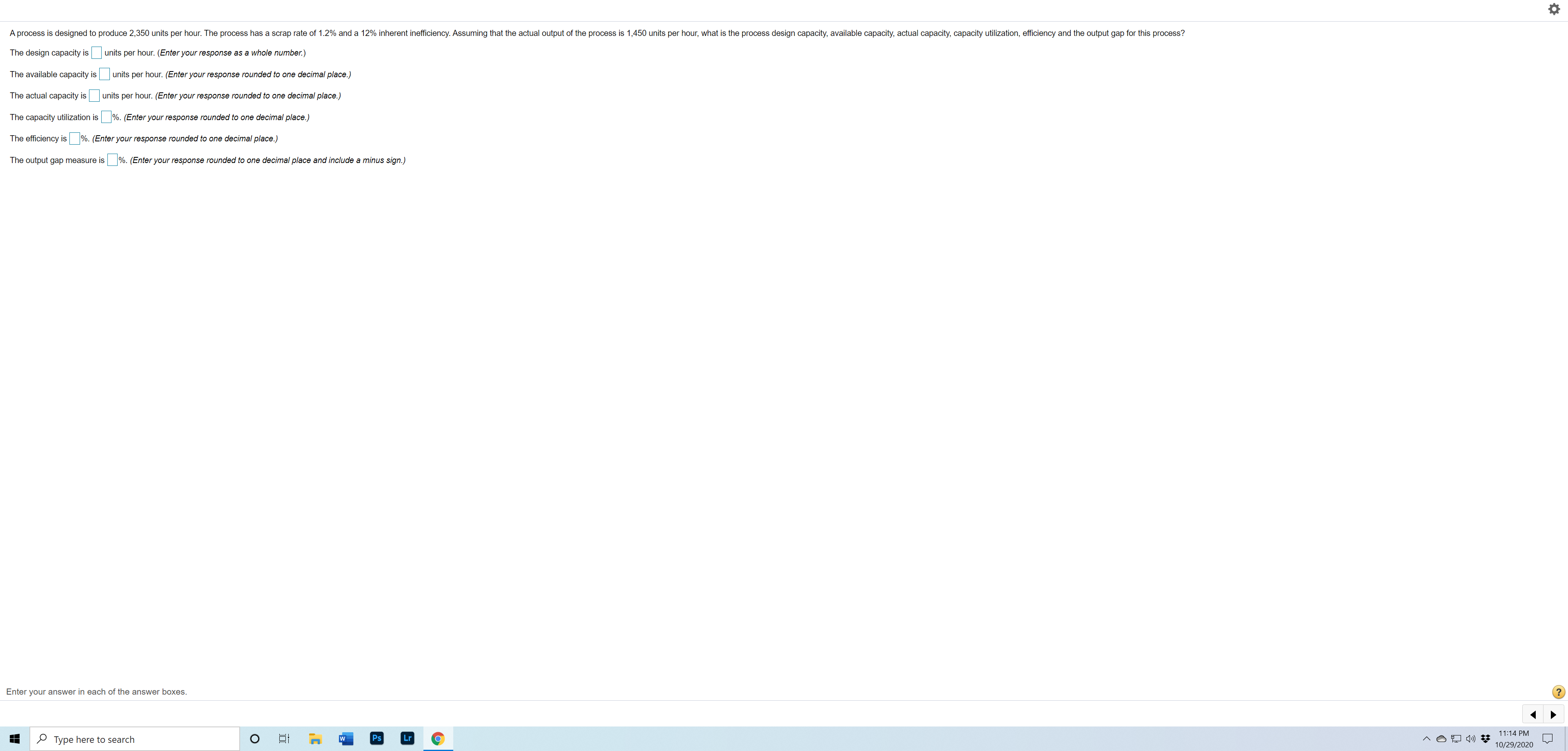

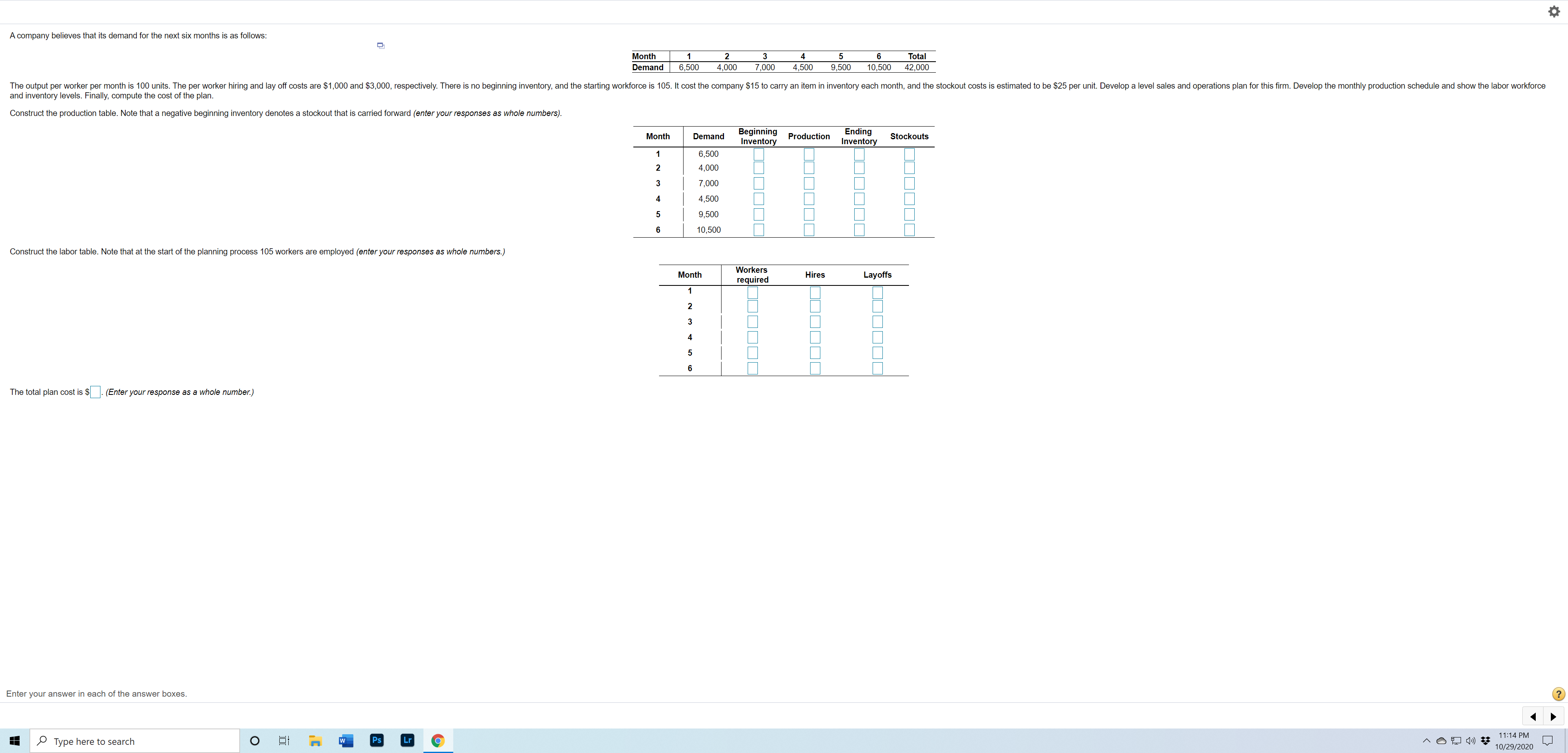

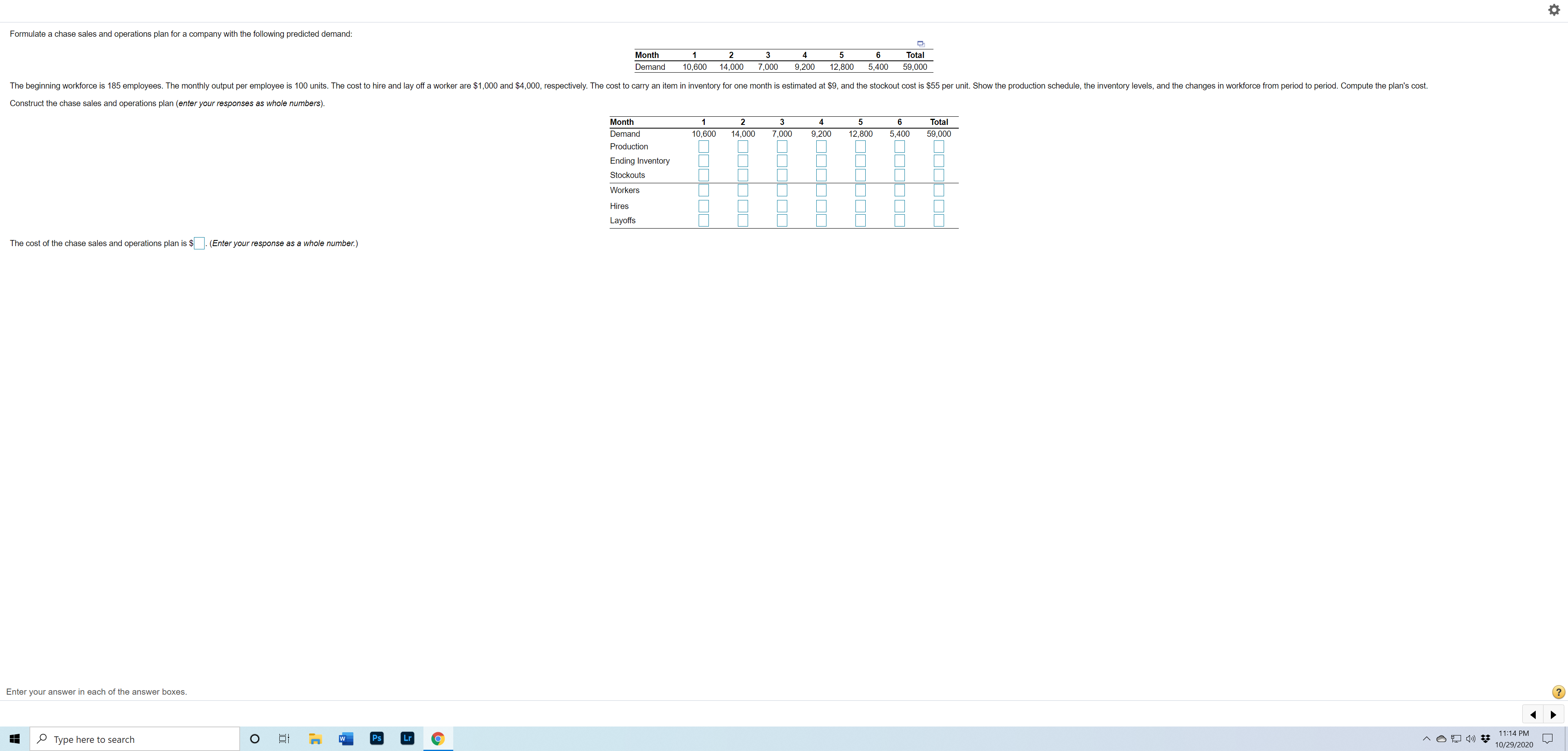

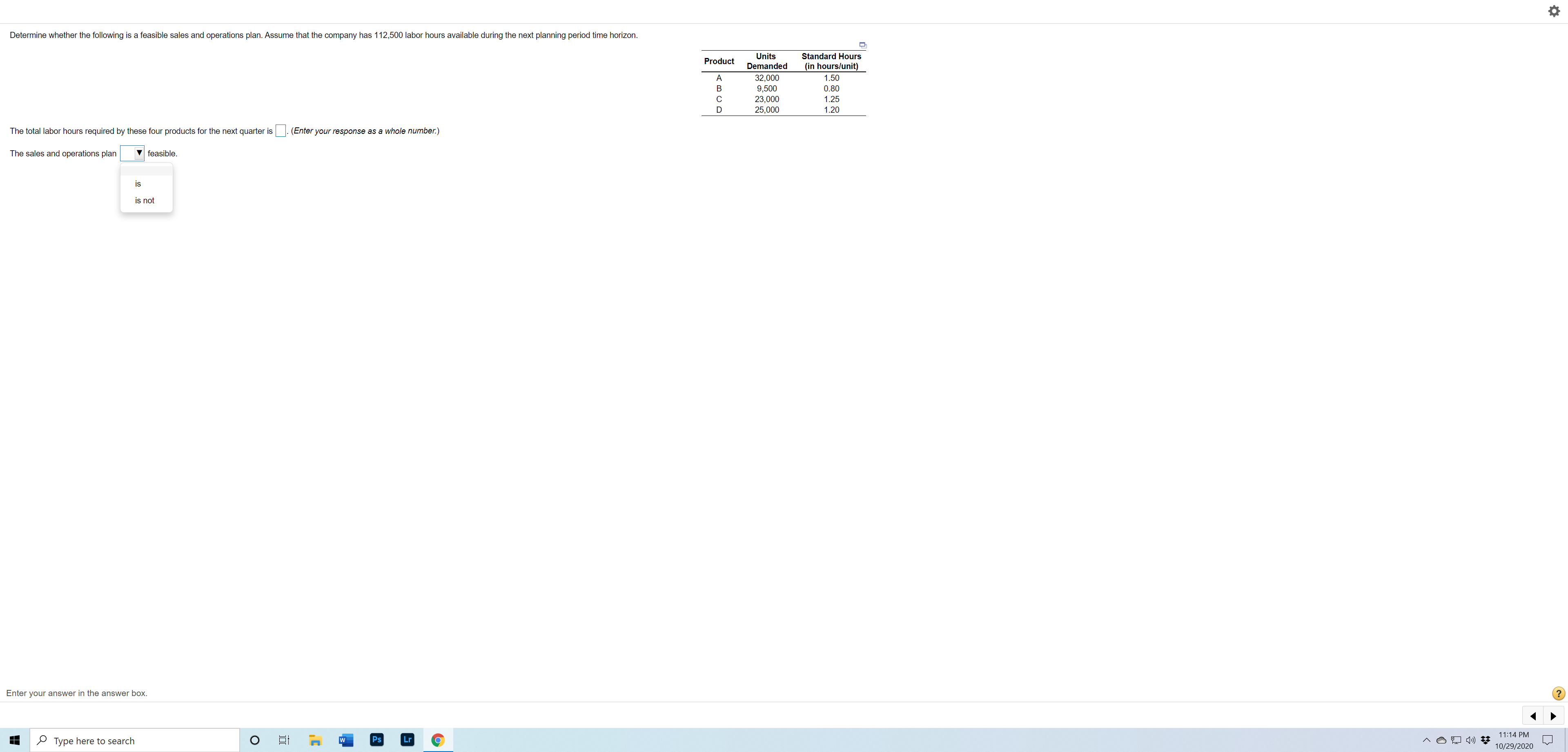

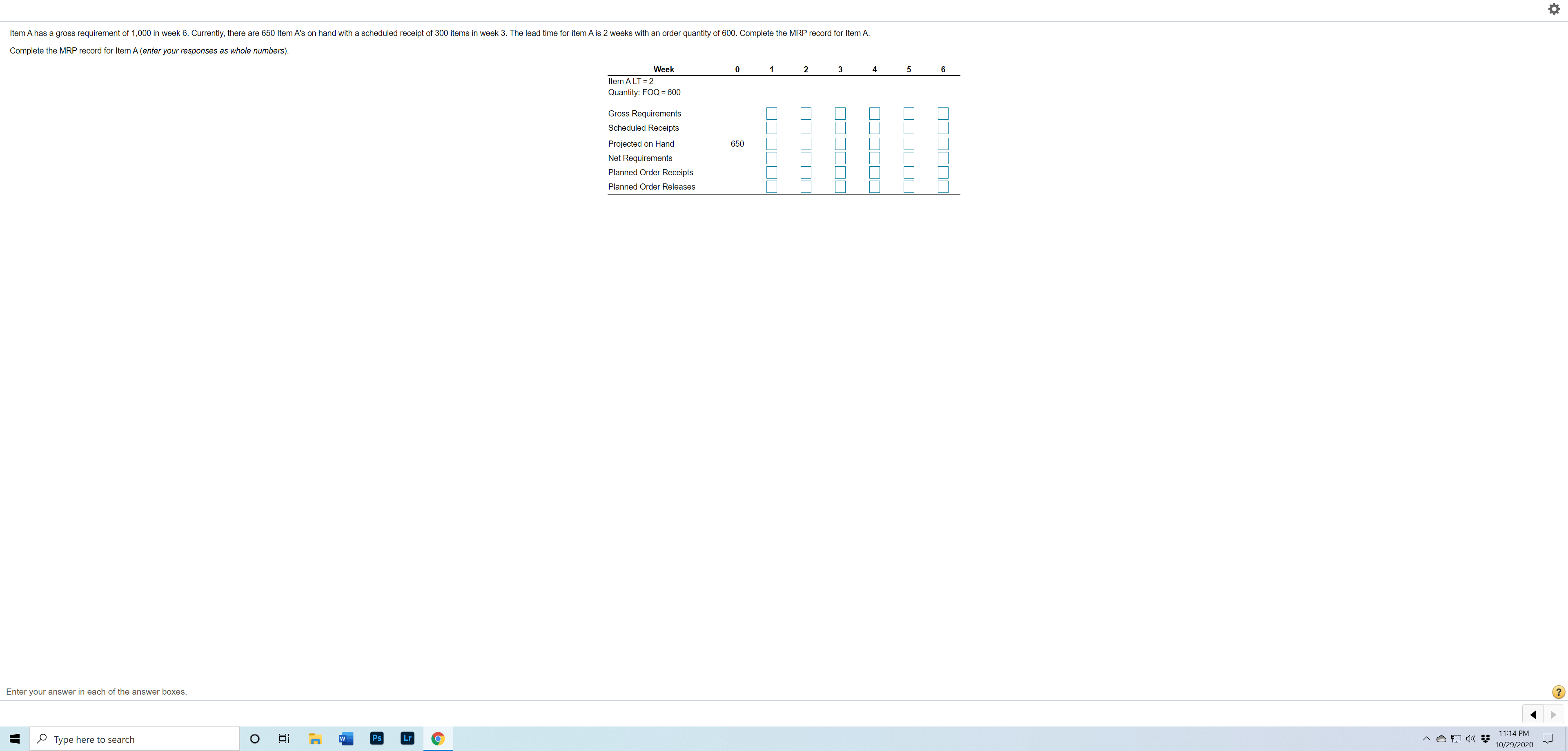

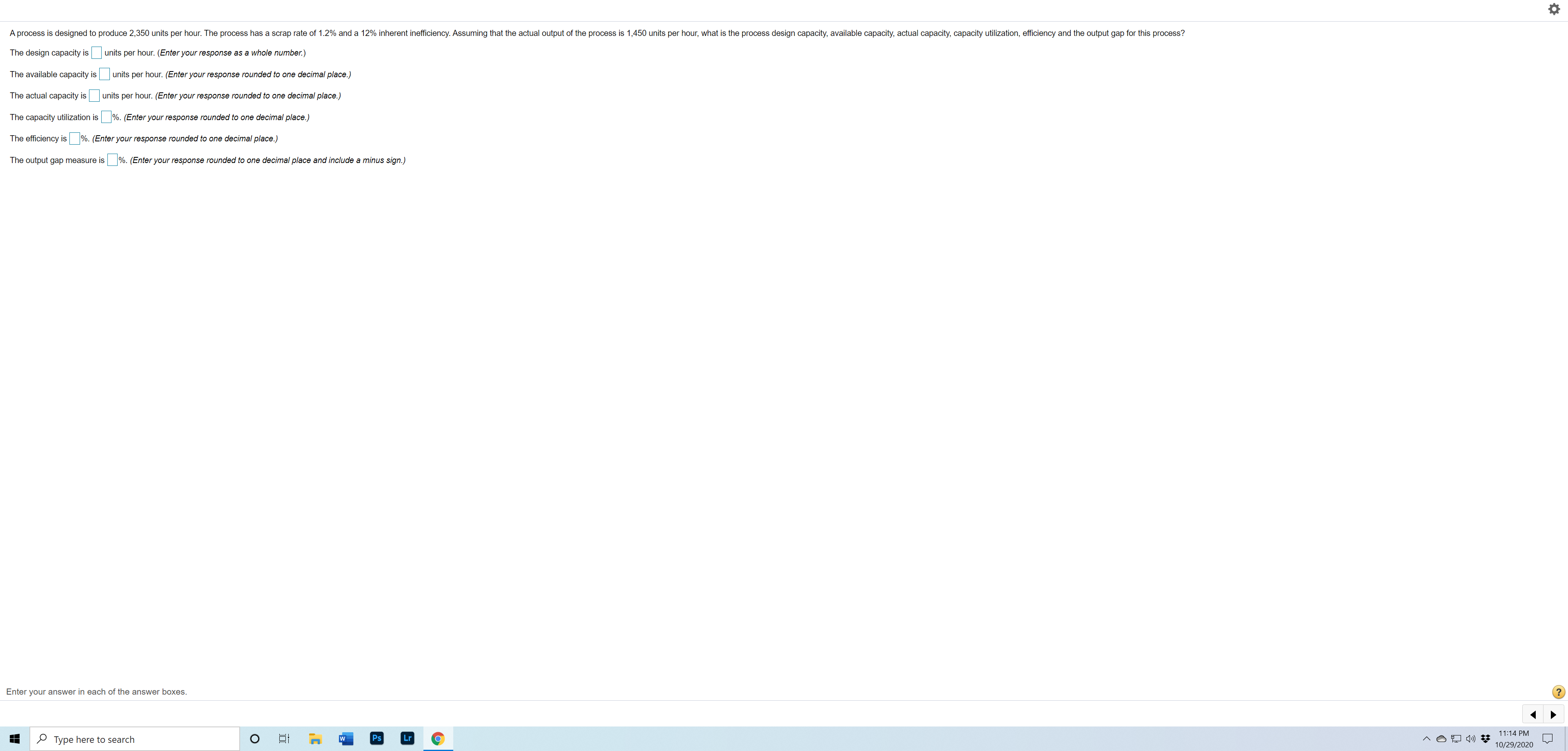

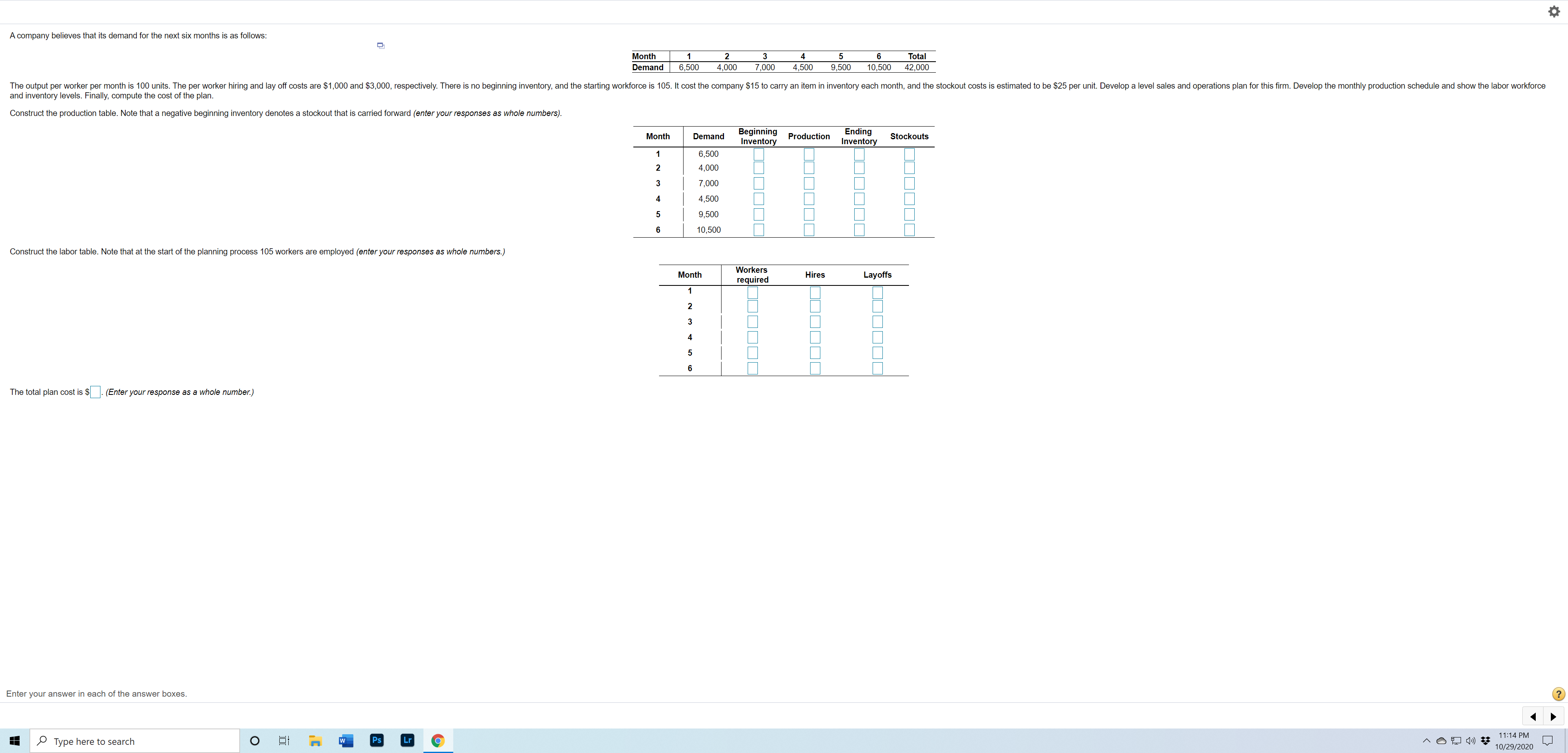

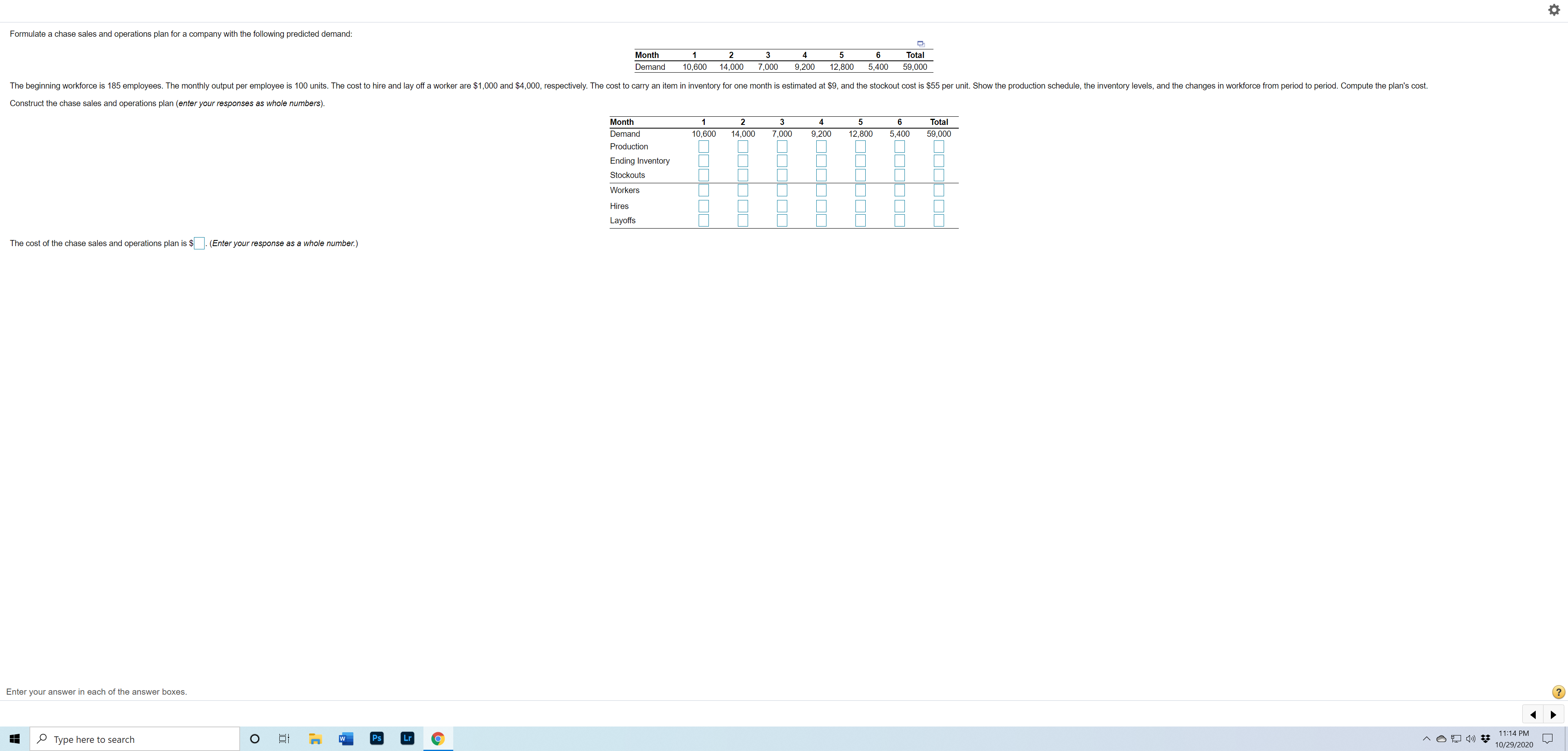

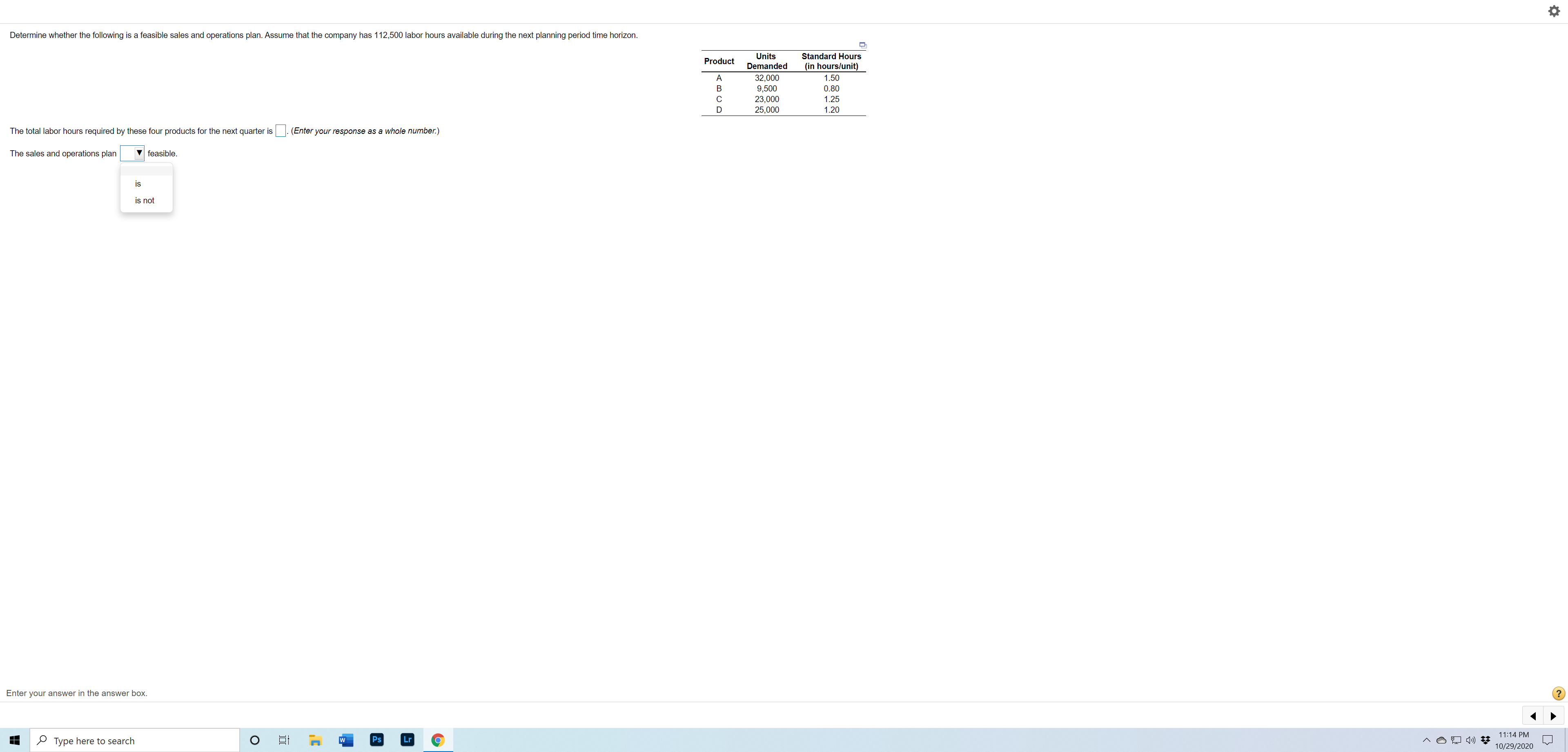

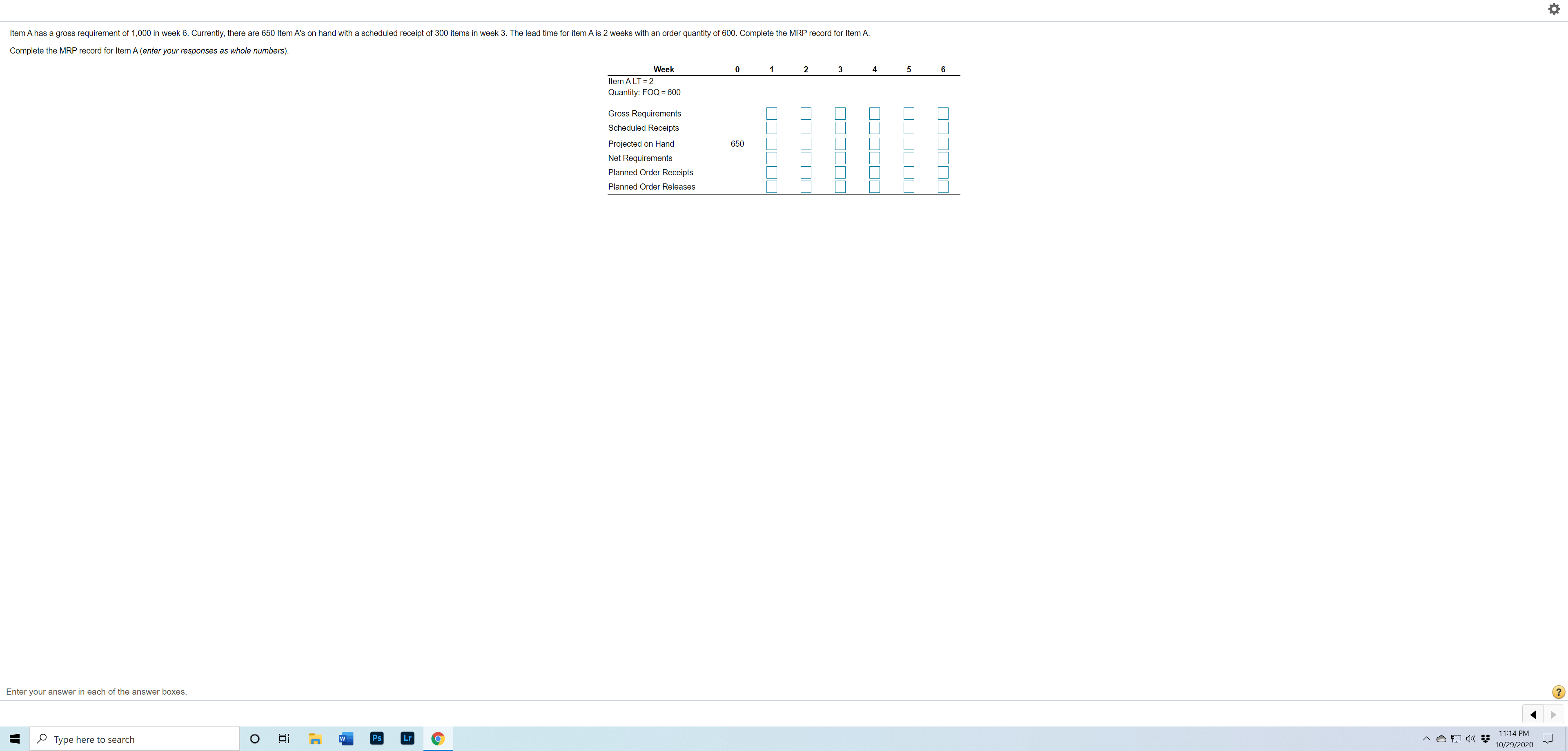

A process is designed to produce 2,350 units per hour. The process has a scrap rate of 1.2% and a 12% inherent inefficiency. Assuming that the actual output of the process is 1,450 units per hour, what is the process design capacity, available capacity, actual capacity, capacity utilization, efficiency and the output gap for this process? The design capacity is units per hour. (Enter your response as a whole number.) The available capacity is units per hour. (Enter your response rounded to one decimal place.) The actual capacity is units per hour. (Enter your response rounded to one decimal place.) The capacity utilization is [%. (Enter your response rounded to one decimal place.) The efficiency is %. (Enter your response rounded to one decimal place.) The output gap measure is %. (Enter your response rounded to one decimal place and include a minus sign.) Enter your answer in each of the answer boxes. ? Type here to search Ps Lr 11:14 PM 10/29/2020 A company believes that its demand for the next six months is as follows: Month Demand 1 6,500 2 4,000 3 7,000 4 4,500 5 9.500 6 10,500 Total 42,000 The output per worker per month is 100 units. The per worker hiring and lay off costs are $1,000 and $3,000, respectively. There is no beginning inventory, and the starting workforce is 105. It cost the company $15 to carry an item in inventory each month, and the stockout costs is estimated to be $25 per unit. Develop a level sales and operations plan for this firm. Develop the monthly production schedule and show the labor workforce and inventory levels. Finally, compute the cost of the plan. Construct the production table. Note that a negative beginning inventory denotes a stockout that is carried forward (enter your responses as whole numbers). Month Demand Beginning Inventory Production Ending Inventory Stockouts 1 6,500 4,000 2 3 7,000 4 4,500 5 9,500 6 10,500 Construct the labor table. Note that at the start of the planning process 105 workers are employed (enter your responses as whole numbers.) Month Workers required Hires Layoffs 1 2 3 4 5 6 The total plan cost is $ (Enter your response as a whole number.) Enter your answer in each of the answer boxes. ? O Type here to search 0 W Ps Lr * 11:14 PM 10/29/2020 Formulate a chase sales and operations plan for a company with the following predicted demand: 4 5 6 Month Demand 1 10,600 2 14,000 3 7,000 Total 59,000 9,200 12,800 5,400 The beginning workforce is 185 employees. The monthly output per employee is 100 units. The cost to hire and lay off a worker are $1,000 and $4,000, respectively. The cost to carry an item in inventory for one month is estimated at $9, and the stockout cost is $55 per unit. Show the production schedule, the inventory levels, and the changes in workforce from period to period. Compute the plan's cost. Construct the chase sales and operations plan (enter your responses as whole numbers). 4 6 Month Demand Production 1 10,600 2 14,000 3 7,000 5 12,800 Total 59,000 9,200 5,400 Ending Inventory Stockouts Workers OOOOI Hires Layoffs The cost of the chase sales and operations plan is $ (Enter your response as a whole number.) Enter your answer in each of the answer boxes. ? 1 O Type here to search W Ps Lr ) 11:14 PM 10/29/2020 Determine whether the following is a feasible sales and operations plan. Assume that the company has 112,500 labor hours available during the next planning period time horizon. Product Standard Hours (in hours/unit) 1.50 . B C Units Demanded 32.000 9,500 23,000 25,000 0.80 1.25 1.20 The total labor hours required by these four products for the next quarter is (Enter your response as a whole number.) The sales and operations plan feasible. is is not Enter your answer in the box. ? O Type here to search o DI W Ps Lr g 11:14 PM 10/29/2020 Item A has a gross requirement of 1,000 in week 6. Currently, there are 650 Item A's on hand with a scheduled receipt of 300 items in week 3. The lead time for item A is 2 weeks with an order quantity of 600. Complete the MRP record for Item A. Complete the MRP record for Item A (enter your responses as whole numbers). 0 1 2 3 4 5 6 Week Item ALT = 2 Quantity: FOQ = 600 650 Gross Requirements Scheduled Receipts Projected on Hand Net Requirements Planned Order Receipts Planned Order Releases Enter your answer in each of the answer boxes. ? Type here to search Ps Lr 11:14 PM 10/29/2020 A process is designed to produce 2,350 units per hour. The process has a scrap rate of 1.2% and a 12% inherent inefficiency. Assuming that the actual output of the process is 1,450 units per hour, what is the process design capacity, available capacity, actual capacity, capacity utilization, efficiency and the output gap for this process? The design capacity is units per hour. (Enter your response as a whole number.) The available capacity is units per hour. (Enter your response rounded to one decimal place.) The actual capacity is units per hour. (Enter your response rounded to one decimal place.) The capacity utilization is [%. (Enter your response rounded to one decimal place.) The efficiency is %. (Enter your response rounded to one decimal place.) The output gap measure is %. (Enter your response rounded to one decimal place and include a minus sign.) Enter your answer in each of the answer boxes. ? Type here to search Ps Lr 11:14 PM 10/29/2020 A company believes that its demand for the next six months is as follows: Month Demand 1 6,500 2 4,000 3 7,000 4 4,500 5 9.500 6 10,500 Total 42,000 The output per worker per month is 100 units. The per worker hiring and lay off costs are $1,000 and $3,000, respectively. There is no beginning inventory, and the starting workforce is 105. It cost the company $15 to carry an item in inventory each month, and the stockout costs is estimated to be $25 per unit. Develop a level sales and operations plan for this firm. Develop the monthly production schedule and show the labor workforce and inventory levels. Finally, compute the cost of the plan. Construct the production table. Note that a negative beginning inventory denotes a stockout that is carried forward (enter your responses as whole numbers). Month Demand Beginning Inventory Production Ending Inventory Stockouts 1 6,500 4,000 2 3 7,000 4 4,500 5 9,500 6 10,500 Construct the labor table. Note that at the start of the planning process 105 workers are employed (enter your responses as whole numbers.) Month Workers required Hires Layoffs 1 2 3 4 5 6 The total plan cost is $ (Enter your response as a whole number.) Enter your answer in each of the answer boxes. ? O Type here to search 0 W Ps Lr * 11:14 PM 10/29/2020 Formulate a chase sales and operations plan for a company with the following predicted demand: 4 5 6 Month Demand 1 10,600 2 14,000 3 7,000 Total 59,000 9,200 12,800 5,400 The beginning workforce is 185 employees. The monthly output per employee is 100 units. The cost to hire and lay off a worker are $1,000 and $4,000, respectively. The cost to carry an item in inventory for one month is estimated at $9, and the stockout cost is $55 per unit. Show the production schedule, the inventory levels, and the changes in workforce from period to period. Compute the plan's cost. Construct the chase sales and operations plan (enter your responses as whole numbers). 4 6 Month Demand Production 1 10,600 2 14,000 3 7,000 5 12,800 Total 59,000 9,200 5,400 Ending Inventory Stockouts Workers OOOOI Hires Layoffs The cost of the chase sales and operations plan is $ (Enter your response as a whole number.) Enter your answer in each of the answer boxes. ? 1 O Type here to search W Ps Lr ) 11:14 PM 10/29/2020 Determine whether the following is a feasible sales and operations plan. Assume that the company has 112,500 labor hours available during the next planning period time horizon. Product Standard Hours (in hours/unit) 1.50 . B C Units Demanded 32.000 9,500 23,000 25,000 0.80 1.25 1.20 The total labor hours required by these four products for the next quarter is (Enter your response as a whole number.) The sales and operations plan feasible. is is not Enter your answer in the box. ? O Type here to search o DI W Ps Lr g 11:14 PM 10/29/2020 Item A has a gross requirement of 1,000 in week 6. Currently, there are 650 Item A's on hand with a scheduled receipt of 300 items in week 3. The lead time for item A is 2 weeks with an order quantity of 600. Complete the MRP record for Item A. Complete the MRP record for Item A (enter your responses as whole numbers). 0 1 2 3 4 5 6 Week Item ALT = 2 Quantity: FOQ = 600 650 Gross Requirements Scheduled Receipts Projected on Hand Net Requirements Planned Order Receipts Planned Order Releases Enter your answer in each of the answer boxes. ? Type here to search Ps Lr 11:14 PM 10/29/2020