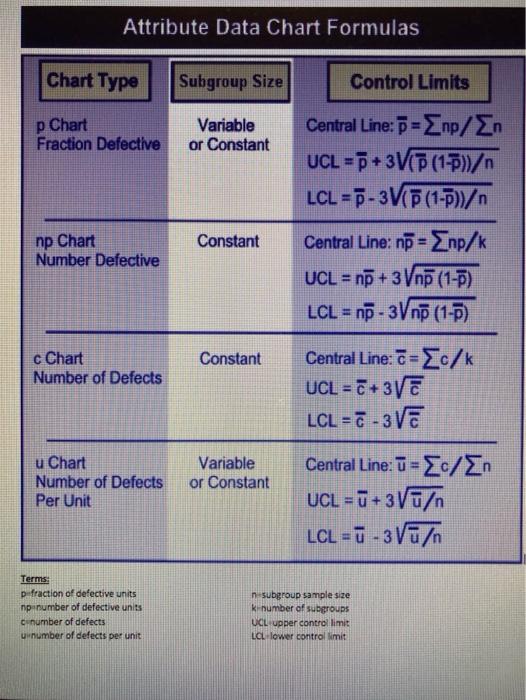

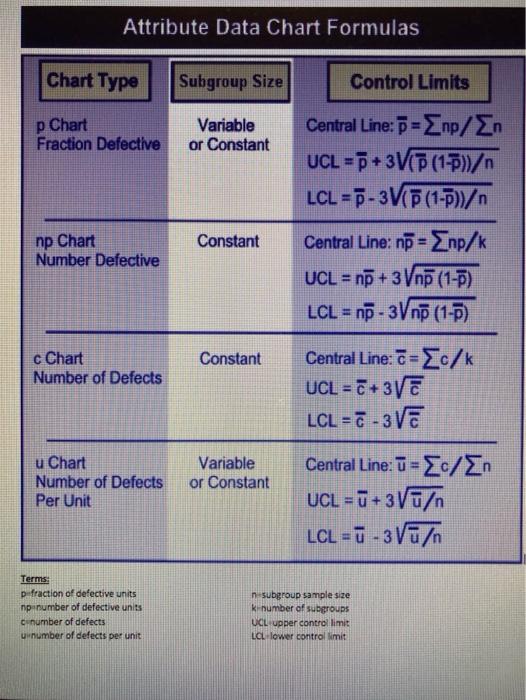

Question: please separate ech question answer (formulars) 1. 2. 3. 4. Attribute Data Chart Formulas Chart Type Subgroup Size Control Limits p Chart Fraction Defective Variable

please separate ech question answer

(formulars)

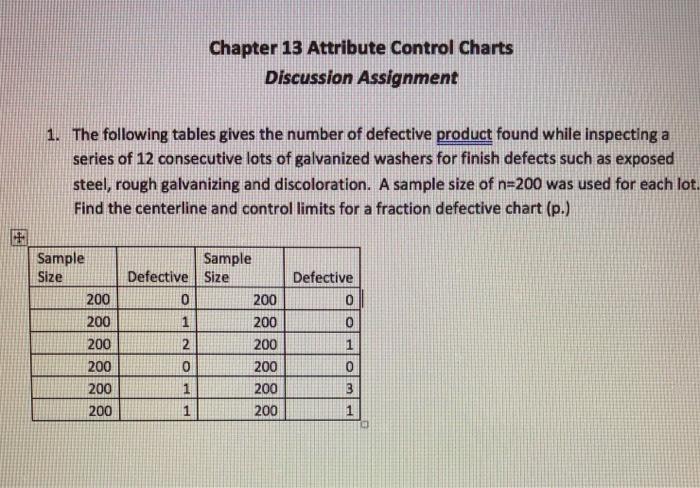

1.

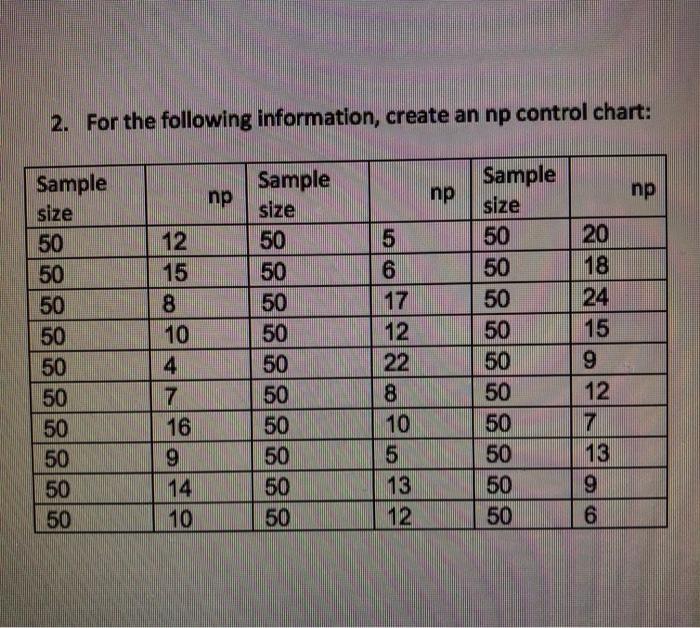

2.

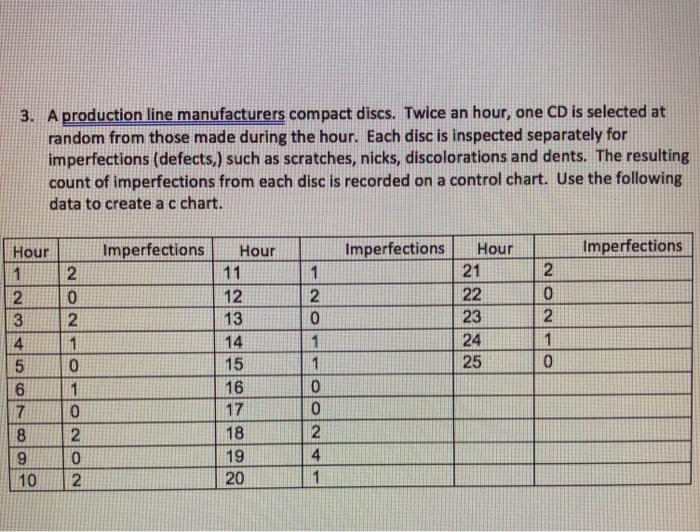

3.

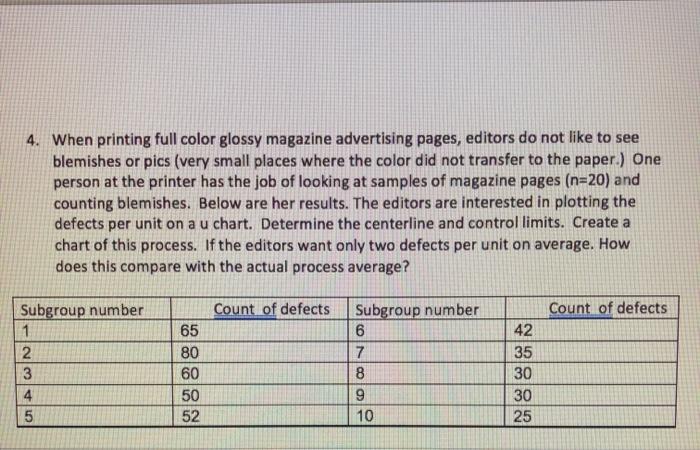

4.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock