Question: please solve this with roll number 126 Complex Engineering Problem You have to design shell-and-tube type heat exchanger. The main aim is to heat water

please solve this with roll number 126

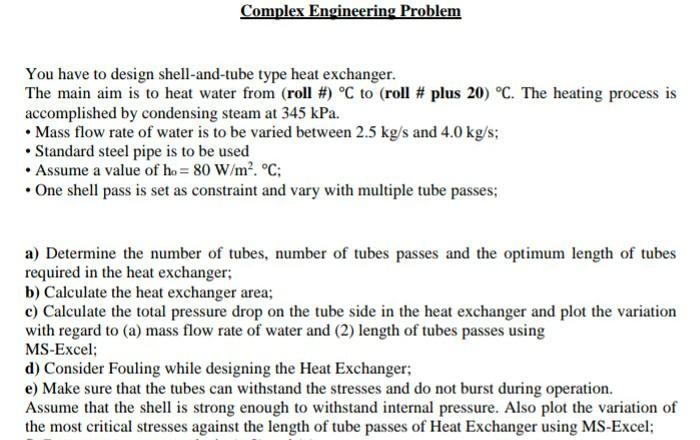

Complex Engineering Problem You have to design shell-and-tube type heat exchanger. The main aim is to heat water from (roll #) C to (roll # plus 20) C. The heating process is accomplished by condensing steam at 345 kPa. Mass flow rate of water is to be varied between 2.5 kg/s and 4.0 kg/s; Standard steel pipe is to be used Assume a value of ho = 80 W/m C; One shell pass is set as constraint and vary with multiple tube passes; a) Determine the number of tubes, number of tubes passes and the optimum length of tubes required in the heat exchanger; b) Calculate the heat exchanger area; c) Calculate the total pressure drop on the tube side in the heat exchanger and plot the variation with regard to (a) mass flow rate of water and (2) length of tubes passes using MS-Excel; d) Consider Fouling while designing the Heat Exchanger; e) Make sure that the tubes can withstand the stresses and do not burst during operation. Assume that the shell is strong enough to withstand internal pressure. Also plot the variation of the most critical stresses against the length of tube passes of Heat Exchanger using MS-Excel

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts