Question: Please take your maximum time and please just solve it perfectly. please answer the question 6 and 7 Question 6 Discuss the manufacturing processes for

Please take your maximum time and please just solve it perfectly. please answer the question 6 and 7

Question 6 Discuss the manufacturing processes for the unidirectional carbon/PEEK single layer skin and injectable short fibers carbon/PEEK. Explain the factors affecting the quality of composite with respect to the selected manufacturing process. Prepare your write up into 3 pages with less than 4 illustrations. (5 marks)

Question 7 Discuss the differences between the continuous and woven fibers composite material when considering Hand Layup manufacturing process. Based on literature review, write a discussion (Not more than 2 pages with less than or equal to 2 illustrations) on the topic (area). You are required to use the Harvard Style to cite references. (5 marks)

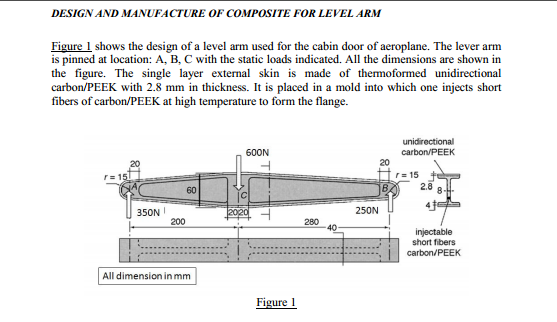

DESIGN AND MANUFACTURE OF COMPOSITE FOR LEVEL ARM Figure 1 shows the design of a level arm used for the cabin door of aeroplane. The lever arm is pinned at location: A, B, C with the static loads indicated. All the dimensions are shown in the figure. The single layer external skin is made of thermoformed unidirectional carbon/PEEK with 2.8 mm in thickness. It is placed in a mold into which one injects short fibers of carbon/PEEK at high temperature to form the flange. 600N unidirectional carbon/PEEK P = 15 60 r = 15 BA 2.8 250N 45 350N 200 280 40 injectable short fibers carbon/PEEK All dimension in mm Figure 1Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts