Question: *PLEASE TYPE YOUR ANSWER (NO SCREENSHOTS OR IMAGES) IN FULL & DETAIL WORKING SOLUTIONS, NO POINT FORM. THANK YOU IN ADVANCE 1. High Tech, Inc.

*PLEASE TYPE YOUR ANSWER (NO SCREENSHOTS OR IMAGES) IN FULL & DETAIL WORKING SOLUTIONS, NO POINT FORM. THANK YOU IN ADVANCE

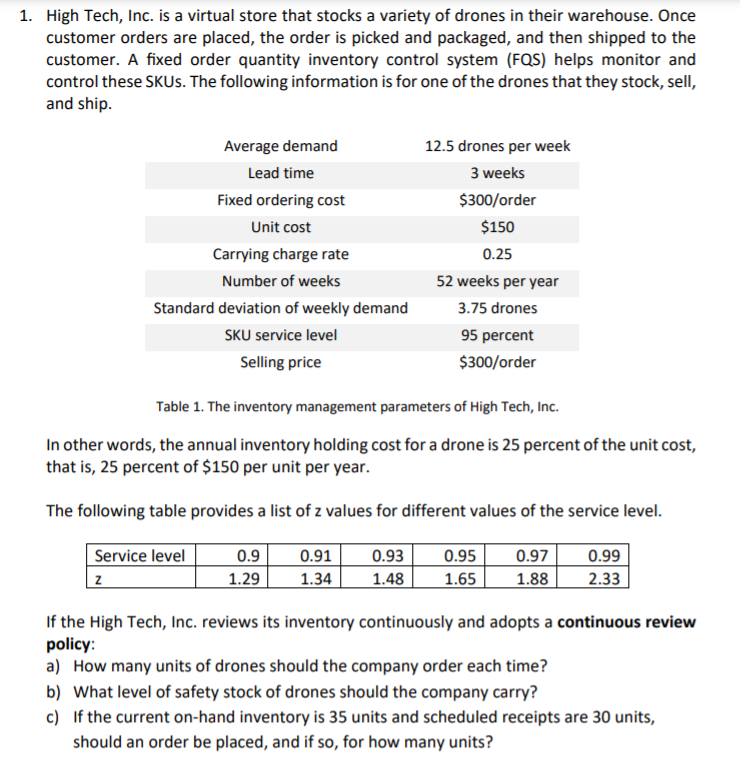

1. High Tech, Inc. is a virtual store that stocks a variety of drones in their warehouse. Once customer orders are placed, the order is picked and packaged, and then shipped to the customer. A fixed order quantity inventory control system (FQS) helps monitor and control these SKUs. The following information is for one of the drones that they stock, sell, and ship Average demand Lead time Fixed ordering cost Unit cost Carrying charge rate Number of weeks Standard deviation of weekly demand SKU service level Selling price 12.5 drones per week 3 weeks $300/order $150 0.25 52 weeks per year 3.75 drones 95 percent $300/order Table 1. The inventory management parameters of High Tech, Inc. In other words, the annual inventory holding cost for a drone is 25 percent of the unit cost, that is, 25 percent of $150 per unit per year. The following table provides a list of z values for different values of the service level. 0.9 Service level z 0.91 1.34 0.93 1.48 0.95 1.65 0.97 1.88 0.99 2.33 1.29 If the High Tech, Inc. reviews its inventory continuously and adopts a continuous review policy a) How many units of drones should the company order each time? b) What level of safety stock of drones should the company carry? c) If the current on-hand inventory is 35 units and scheduled receipts are 30 units, should an order be placed, and if so, for how many unitsStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts