Question: Problem 2 ( 4 0 points ) Open with Google Docs It is summertime and your winter coat factory is trying to decide its production

Problem points

Open with Google Docs

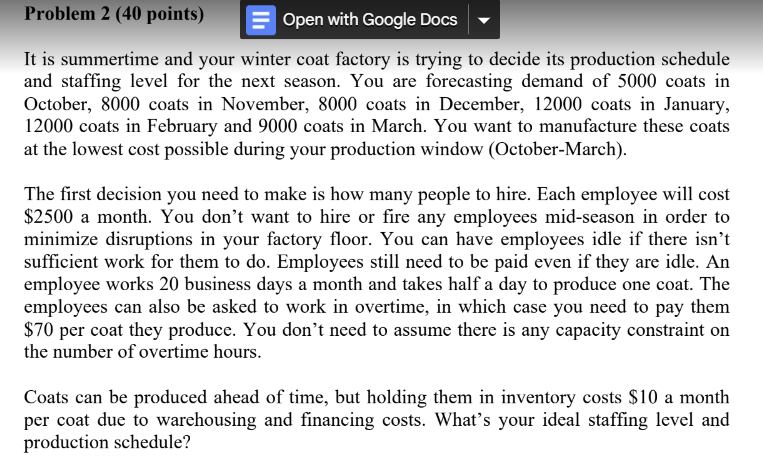

It is summertime and your winter coat factory is trying to decide its production schedule

and staffing level for the next season. You are forecasting demand of coats in

October, coats in November, coats in December, coats in January,

coats in February and coats in March. You want to manufacture these coats

at the lowest cost possible during your production window OctoberMarch

The first decision you need to make is how many people to hire. Each employee will cost

$ a month. You don't want to hire or fire any employees midseason in order to

minimize disruptions in your factory floor. You can have employees idle if there isn't

sufficient work for them to do Employees still need to be paid even if they are idle. An

employee works business days a month and takes half a day to produce one coat. The

employees can also be asked to work in overtime, in which case you need to pay them

$ per coat they produce. You don't need to assume there is any capacity constraint on

the number of overtime hours.

Coats can be produced ahead of time, but holding them in inventory costs $ a month

per coat due to warehousing and financing costs. What's your ideal staffing level and

production schedule?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock