Question: Problem (2) (Use Rework and Assembly product method) : Steel making manufacturers purchases two types of parts P1 and P2 from third party to meet

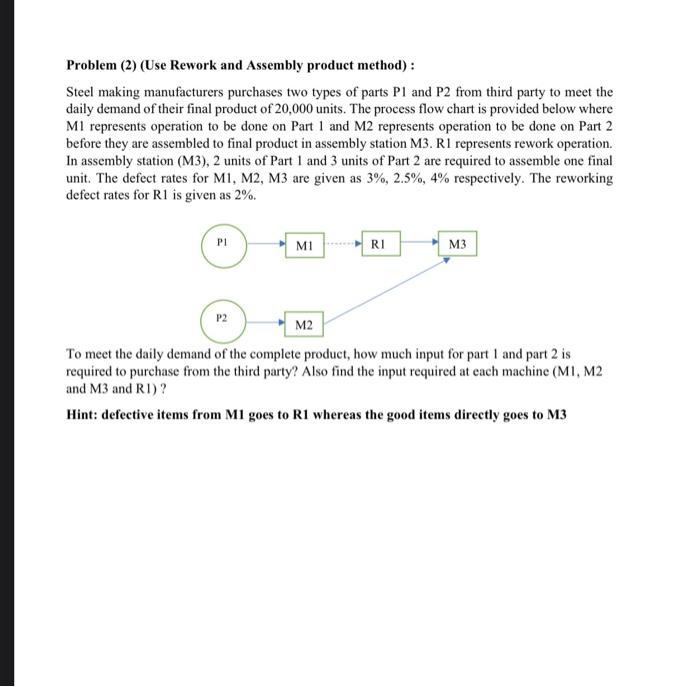

Problem (2) (Use Rework and Assembly product method) : Steel making manufacturers purchases two types of parts P1 and P2 from third party to meet the daily demand of their final product of 20,000 units. The process flow chart is provided below where M1 represents operation to be done on Part 1 and M2 represents operation to be done on Part 2 before they are assembled to final product in assembly station M3. R1 represents rework operation. In assembly station (M3), 2 units of Part 1 and 3 units of Part 2 are required to assemble one final unit. The defect rates for M1,M2,M3 are given as 3%,2.5%,4% respectively. The reworking defect rates for R1 is given as 2%. To meet the daily demand of the complete product, how much input for part 1 and part 2 is required to purchase from the third party? Also find the input required at each machine (M1, M2 and M3 and R1 ) ? Hint: defective items from M1 goes to R1 whereas the good items directly goes to M3

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts