Question: Problem Statement: You are working as a Design Engineer in a manufacturing facility where the automation and material handling plays a major role in the

Problem Statement: You are working as a Design Engineer in a manufacturing facility where

the automation and material handling plays a major role in the line assembly. Your

managersupervisor has assigned you a task of lifting components from a conveyer belt. You

have been provided parts SolidWorks CAD files only. You are required to understand the

mechanism and put the parts together to make an Assembly so the mechanism can later be put

together by a team of technicians. Be an engineer and amend the areas that are not correct while

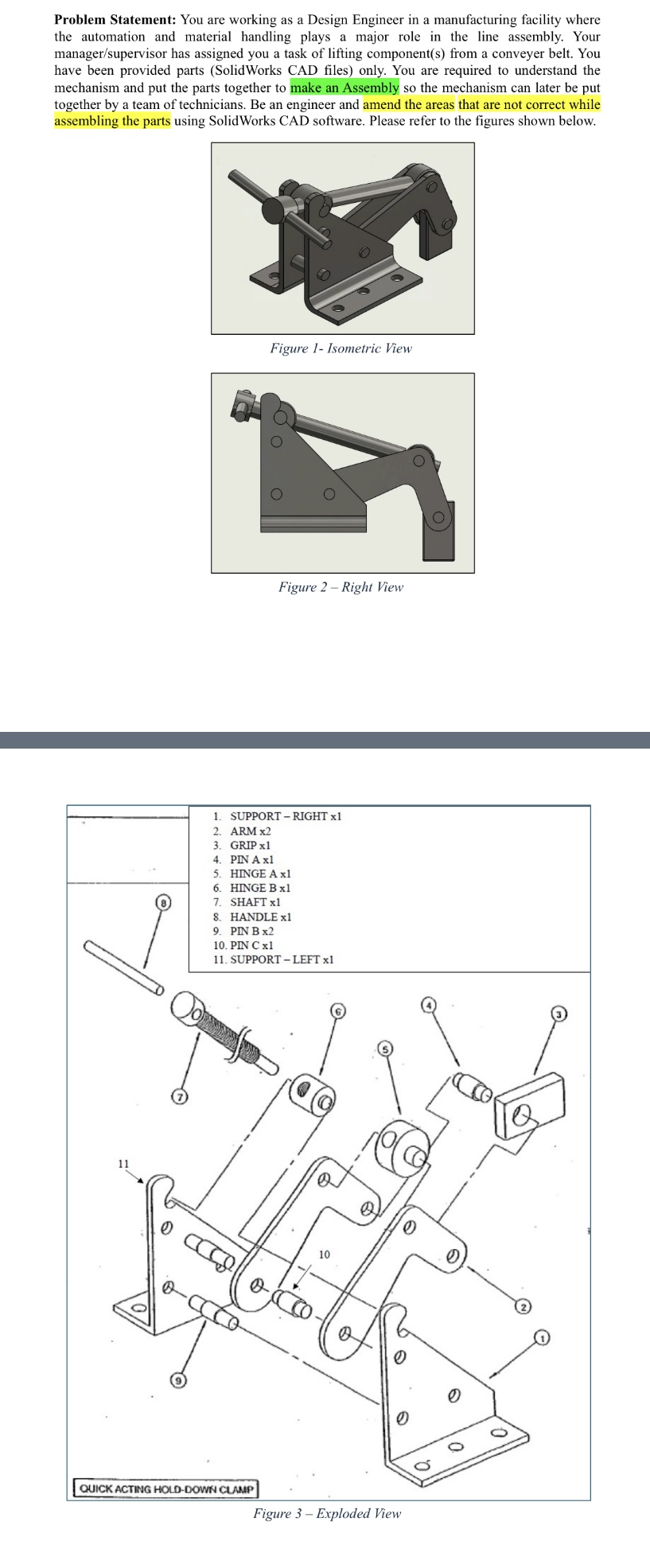

assembling the parts using SolidWorks CAD software. Please refer to the figures shown below.

Figure Isometric View

Figure Exploded View

Amendments:

These amendments will allow you to successfully complete your Project. Each amendment has a video associated to it Make sure to watch the videos as they will be of great help in achieving each necessary amendment.

Make sure fasteners are properly dimensioned with other parts in the assembly no visible gaps between pins and other parts

Make sure that the assembly moves properly Screw mate between Shaft and Hinge B

Note: The screw of the assembly has a cosmetic thread but is mated in a similar way to that of a normal screw.

Make sure parts have reduced interferences.

Note: In the case of the screw assembly interferences shouldn't be more than in in all other cases interferences should be less than in

Further Considerations:

There are several pin types make sure to place them in their appropriate location see Figure

Exploded View

The right support must be fixed not floating and consequently should be the first part added to the assembly space.

All parts other than the right support must float, with their respective positions defined using mates.

Use a Limit mate Limit Distance or Limit Angle to control the assembly's range of motion to match the movement demonstrated in the provided video ExtraCredit

The grip must remain vertical throughout the range of motion.

All pins must be centered with respect to the two supports.

You may not use the "Lock" mate, but you may select the option to lock rotation in a Concentric mate to fully define a cylindrical component pin with no other useable features.

The handle must be centered with respect to the shaft.

Please help with a step by step with pictures on how to do this in SolidWorks.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock