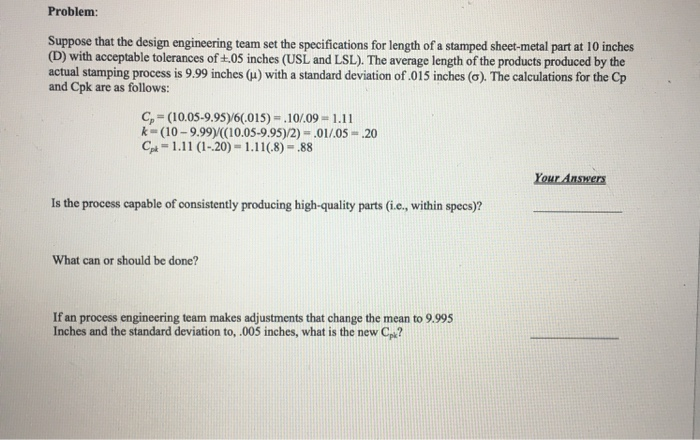

Question: Problem: Suppose that the design engineering team set the specifications for length of a stamped sheet-metal part at 10 inches (D) with acceptable tolerances of

Step by Step Solution

There are 3 Steps involved in it

To answer this question we need to first assess the given values and calculate the process capability indices Cp and Cpk which will help us determine ... View full answer

Get step-by-step solutions from verified subject matter experts