Question: Q. 1 Read the small case study about Cadbury Schweppes given below. In the case study it is stated that Cadbury Schweppes uses batch production

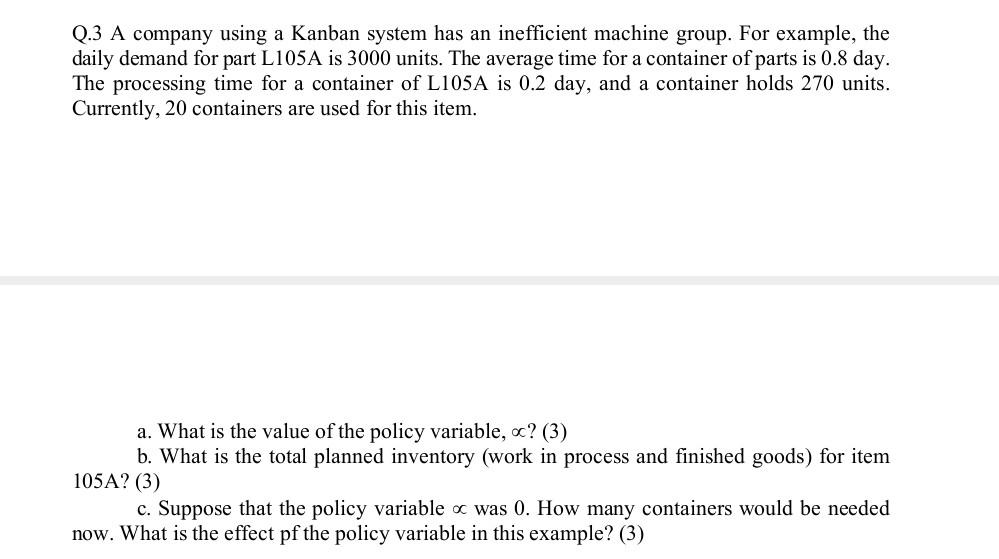

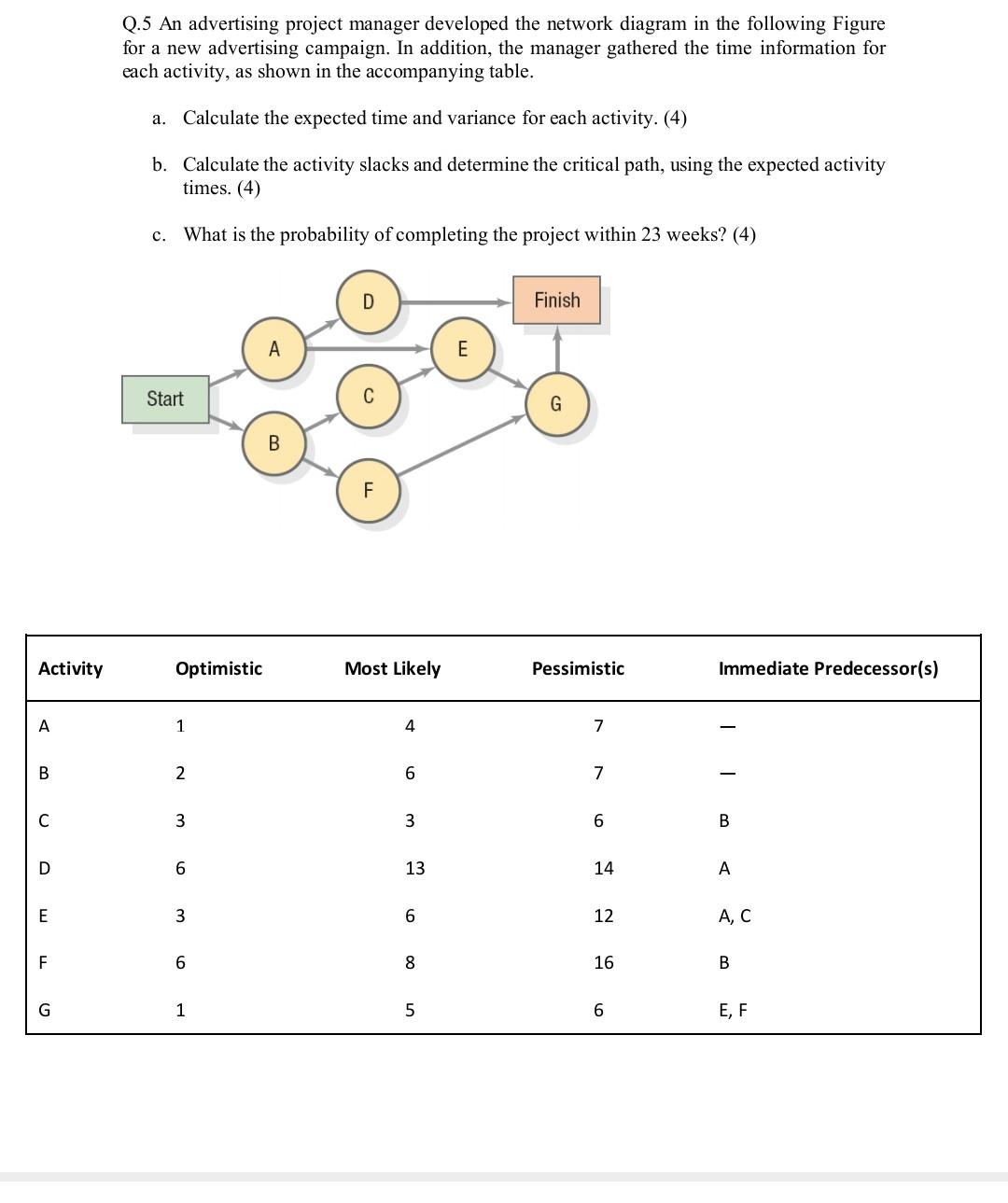

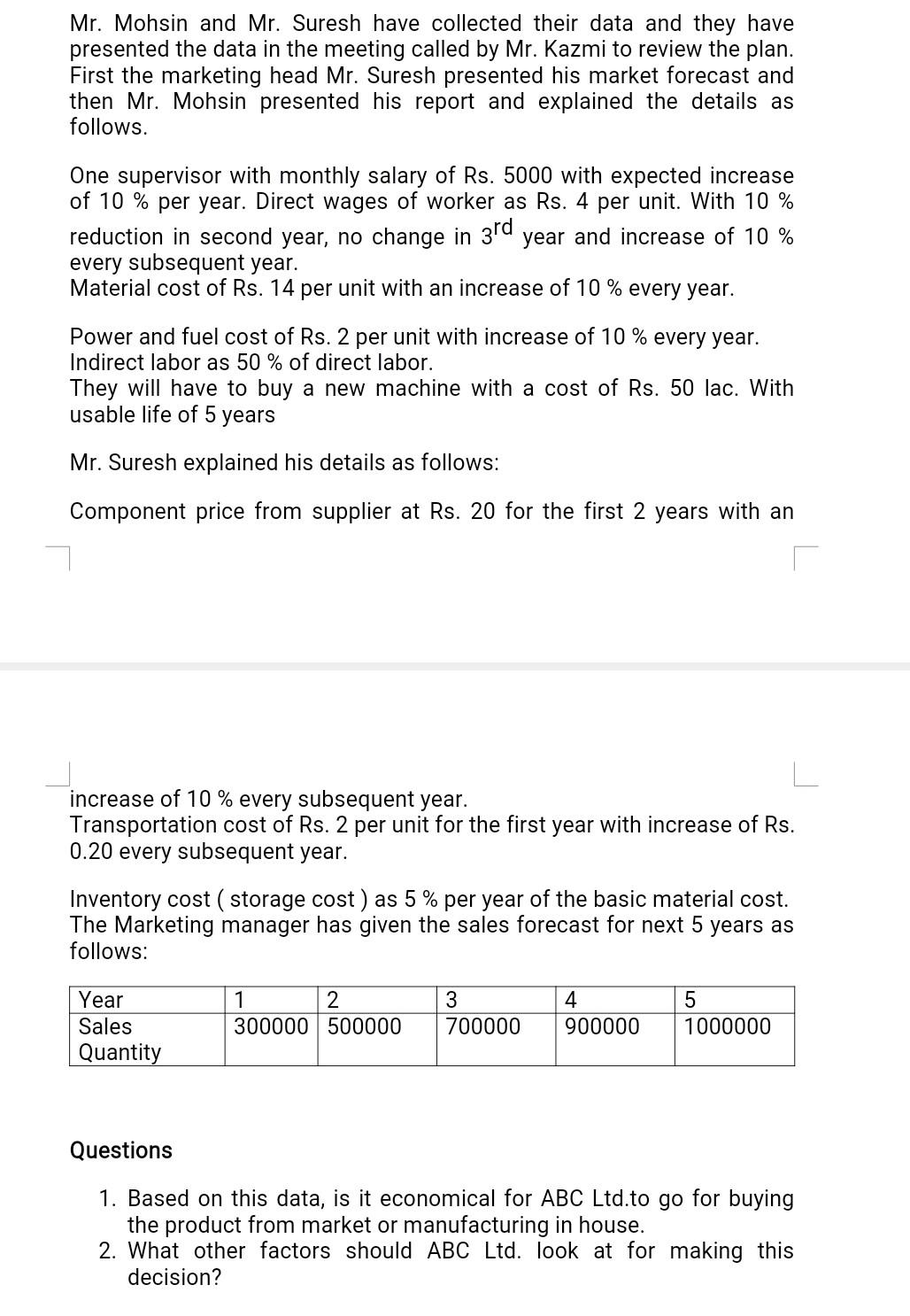

Q. 1 Read the small case study about Cadbury Schweppes given below. In the case study it is stated that Cadbury Schweppes uses batch production methods to make its products and that it is important the products are of high quality. Based on the information provided (a) critically evaluate the reasons why Cadbury Schweppes uses batch production when making chocolate bars. (5 Marks) (b) critically discuss which of the following two quality control methods would be better for Cadbury Schweppes: .checking samples of the products after they have been made making workers responsible for the quality of their own work (4 Marks) Case Study - Cadbury Schweppes Production Method Cadbury Schweppes is a multinational soft drinks (beverages) and confectionery business that is based in the UK. The business is a public limited company. It is involved in the manufacture, marketing and distribution of its many branded products. Cadbury Schweppes now employs over 40000 people and its products are available in almost 200 countries. The company's products can be divided into: Beverages (carbonated soft drinks and non-carbonated soft drinks (waters and fruit juices) Confectionery (chocolate products, sugar products, chewing gum) Much of Cadbury Schweppes' manufacturing still takes place in the UK, Australia and North Africa. However, in the 1990s the company moved some of its production to Russia, Poland, Argentina and China, countries with emerging economies. To satisfy most of its shareholders, Cadbury Schweppes' has set out a strategy to help achieve its objective. This strategy consists of: Creating strong regional positions through organic growth, acquisitions and disposals Developing strong brands through marketing Expanding its marketing share through innovation in products and packaging Regularly updating its product portfolio Production Despite manufacturing its goods in large quantities, Cadbury Schweppes uses batch rather than flow production methods. The company must ensure the products are of high quality. Not only are there strict laws about how foodstuff is made, but also Cadbury Schweppes would not want to damage its reputation by allowing inferior products to be sold. Cadbury Schweppes undertakes extensive research and development (R&D) to develop new products and to find ways of manufacturing existing brands more efficiently. Cadbury Schweppes uses the services of a specialist R&D business based at Reading for its UK confectionery business. Q.3 A company using a Kanban system has an inefficient machine group. For example, the daily demand for part L105A is 3000 units. The average time for a container of parts is 0.8 day. The processing time for a container of L105A is 0.2 day, and a container holds 270 units. Currently, 20 containers are used for this item. a. What is the value of the policy variable, oc? (3) b. What is the total planned inventory (work in process and finished goods) for item 105A? (3) c. Suppose that the policy variable oc was 0. How many containers would be needed now. What is the effect pf the policy variable in this example? (3) Q.5 An advertising project manager developed the network diagram in the following Figure for a new advertising campaign. In addition, the manager gathered the time information for each activity, as shown in the accompanying table. a. Calculate the expected time and variance for each activity. (4) b. Calculate the activity slacks and determine the critical path, using the expected activity times. (4) c. What is the probability of completing the project within 23 weeks? (4) D Finish A E Start G B F Activity Optimistic Most Likely Pessimistic Immediate Predecessor(s) A 1 4 7 B 2 6 7 C 3 3 6 B D 6 13 14 A E 3 6 12 AC F 6 8 16 B G 1 5 6 E, F Case Study 1 Make Versus Buy Case ABC Ltd. is a manufacturing company engaged in the manufacturing of valves. They have been in the business for last 3 years and have been manufacturing only one type of valves. They started their business initially with sales of 10,000 valves per month and now they have grown the volume to about 50,000 valves per month. They have been buying all the raw material for the valve and were doing all the manufacturing in house. Now they have established themselves in the market and are planning to expand and produce different varieties of valves. They have their plant in the main city and the total area of the plant is 50,000 sq. ft. Now if they want to expand and continue doing all the activities of manufacturing of all the varieties in house, they would need another 50,000 sq.ft. of the area. In the recent times, the land prices in the area have more than doubled in the last 3 years and still land is available with great difficulty. Mr. Mohsin is the production head of ABC Ltd. and has been successful with the production and the level is continuously increasing. But in recent times, he is facing the problem of quality complaints which have gone up from average 0.2 % in previous 2 years to 0.5 % this year. Also, he is finding that there is a high level of dissatisfaction among the workers regarding workload as well as salary levels. The workers are regularly complaining about the over work. Although, Mr. Mohsin has found that the workers have been spending lot of time on tea breaks, lunch breaks and even in between the production spending lot of time talking to each other. But, due to insufficient workers and staff, he is unable to take strict action and the workers are taking advantage of this situation. For completing the work and delivering the products timely, he has to employ workers on overtime and his overtime cost has also increased 3 times. Mr. Mohsin is worried about the new expansion plan of the management and is worried where the new workers would come from as he is already finding shortage of workers for the existing job. He has requested the management not to go for expansion immediately and look at improving and consolidating the existing set up. He has sent his request to Mr. S. Kazmi Director Operations. Mr. Kazmi has gone through the request of Mr. Mohsin and called a meeting of all the department heads and explained the situation to all concerned. The marketing manager has expressed very bullish prospect about the company's growth and said that the company should take advantage of growing economy and established brand image of the company and definitely go for expansion. The finance manger also expressed that this will result in economy of scale for the products and will further increase the profitability of the products. Mr. Mohsin again expressed his problems regarding availability of manpower as well as production control and effect on quality and productivity. The Marketing manager asked the Production manager about the option of outsourcing. Mr. Mr. Mohsin and Mr. Suresh have collected their data and they have presented the data in the meeting called by Mr. Kazmi to review the plan. First the marketing head Mr. Suresh presented his market forecast and then Mr. Mohsin presented his report and explained the details as follows. One supervisor with monthly salary of Rs. 5000 with expected increase of 10 % per year. Direct wages of worker as Rs. 4 per unit. With 10 % reduction in second year, no change in 3rd year and increase of 10 % every subsequent year. Material cost of Rs. 14 per unit with an increase of 10 % every year. Power and fuel cost of Rs. 2 per unit with increase of 10 % every year. Indirect labor as 50 % of direct labor. They will have to buy a new machine with a cost of Rs. 50 lac. With usable life of 5 years Mr. Suresh explained his details as follows: Component price from supplier at Rs. 20 for the first 2 years with an increase of 10 % every subsequent year. Transportation cost of Rs. 2 per unit for the first year with increase of Rs. 0.20 every subsequent year. Inventory cost ( storage cost ) as 5% per year of the basic material cost. The Marketing manager has given the sales forecast for next 5 years as follows: Year Sales Quantity 1 2 300000 500000 3 700000 4 900000 5 1000000 Questions 1. Based on this data, is it economical for ABC Ltd.to go for buying the product from market or manufacturing in house. 2. What other factors should ABC Ltd. look at for making this decision

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock