Question: Q2. In this process, maple syrup is heated as it passes through a steam heat exchanger, then enters an evaporator where the water boils off.

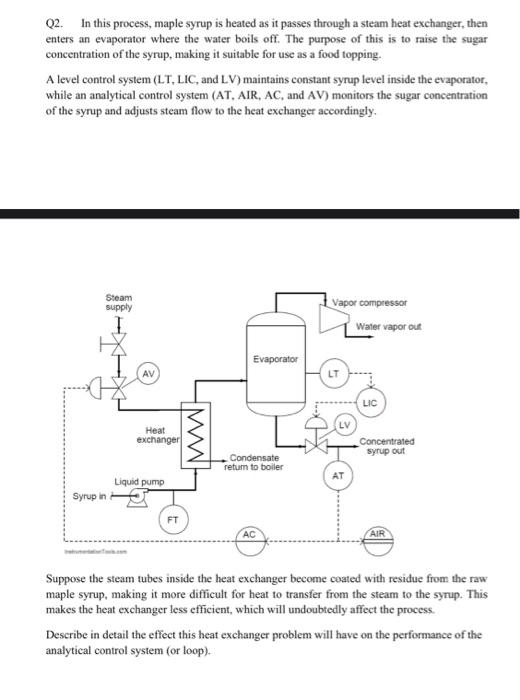

Q2. In this process, maple syrup is heated as it passes through a steam heat exchanger, then enters an evaporator where the water boils off. The purpose of this is to raise the sugar concentration of the syrup, making it suitable for use as a food topping. A level control system (LT, LIC, and LV) maintains constant syrup level inside the evaporator, while an analytical control system (AT, AIR, AC, and AV) monitors the sugar concentration of the syrup and adjusts steam flow to the heat exchanger accordingly. Suppose the steam tubes inside the heat exchanger become coated with residue from the raw maple syrup, making it more difficult for heat to transfer from the steam to the syrup. This makes the heat exchanger less efficient, which will undoubtedly affect the process. Describe in detail the effect this heat exchanger problem will have on the performance of the analytical control system (or loop)

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts