Question: QUEST ON 1 TABLE 1 and TABLE 2 / / / / / / / / / / / Part 1 . Discussion of Lab#

QUESTON TABLE and TABLE

Part Discussion of Lab# Results

Introduction: Provide a short description of the scope of the study and information on aggregate. The Introduction section should be written in your own words, and not copied from the laboratory manual. The Introduction should first state the objective of the experiment conducted in the laboratory and then give any necessary background information, such as what theories the experiment was intended to test, validate, or exemplify. Remember to use citations for any

Use point type for text, captions, and author contact information. For typing within figures or tables, the point size is preferred. Please use the text font Times Roman. Italics and bold formats may be used; we recommend sticking to one "family" of typefaces. The paper must be written in the best possible technical and grammatical English Questions

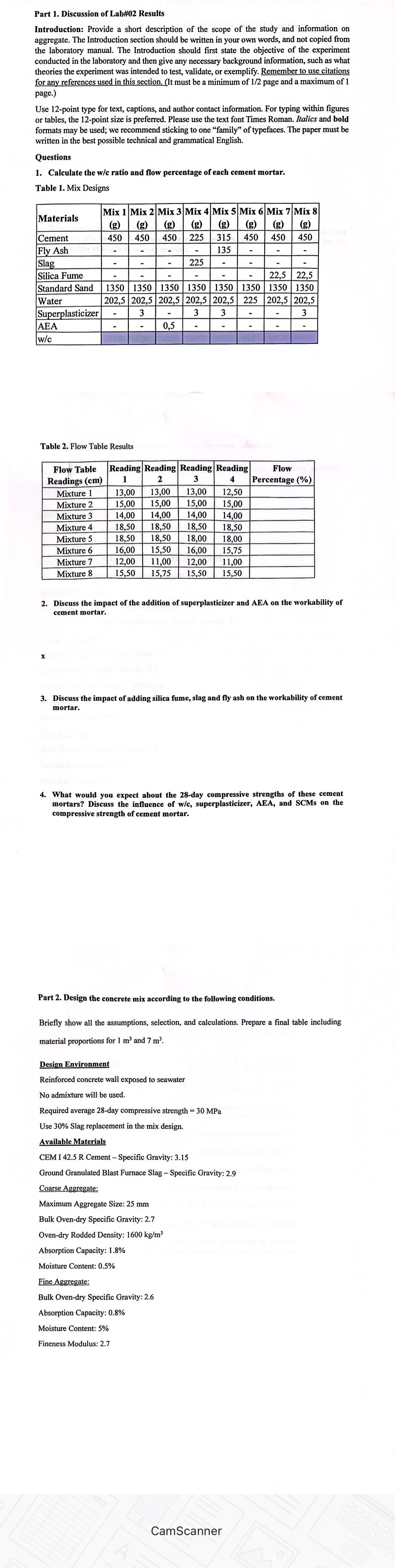

Calculate the wc ratio and flow percentage of each cement mortar Table Mix Design

tableMaterialstableMix gtableMix gtableMix gtableMix gtableMix gtableMix gtableMix gtableMix gCementFly Ash,SlagSilica Fume,Standard Sand,WaterSuperplasticizerAEAwc

Tahle Flow Table Results

Discuss the impact of the addition of superplasticizer and AEA on the workability of cement mortar.

Discuss the impact of adding silica fume, slag and fly ash on the workability of cement Dortar.

What would you expect about the day compressive strengths of these cemen mortars? Discuss the influence of wc compressive strength of cement mortar.

Part Design the concrete mix according to the following conditions.

Briefly show all the assumptions, selection, and calculations. Prepare a final table including material proportions for and

Design Environment

Reinforced concrete wall exposed to seawater

No admixture will be used.

Required average day compressive strength MPa

Use Slag replacement in the mix design.

Available Materials

CEM I R Cement Specific Gravity:

Ground Granulated Blast Furnace Slag Specific Gravity:

Coarse Aggregate:

Maximum Aggregate Size:

Bulk Ovendry Specific Gravity:

Ovendry Rodded Density:

Absorption Capacity:

Moisture Content:

Fine Aggregate:

Bulk Ovendry Specific Gravity:

Absorption Capacity:

Moisture Content:

Fineness Modulus:

CamScanner

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock