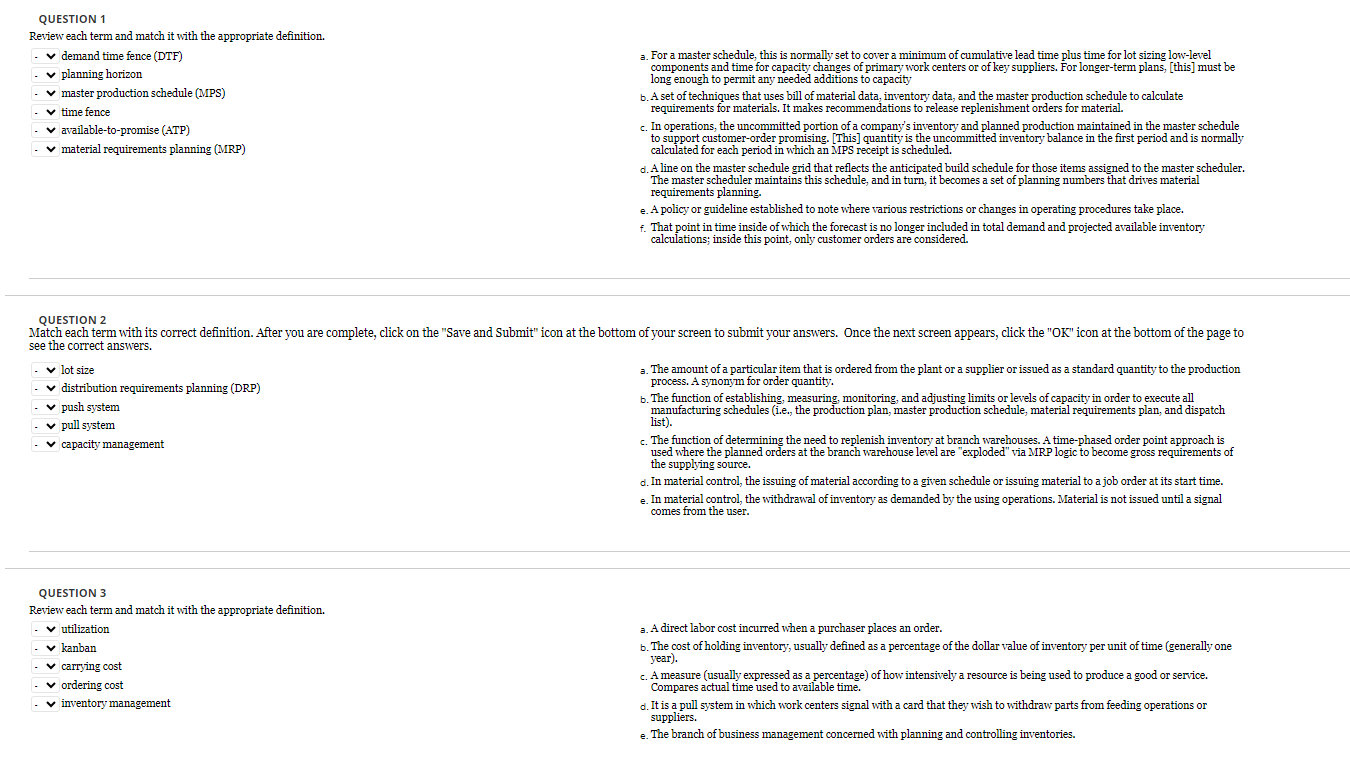

Question: QUESTION 1 Review each term and match it with the appropriate definition. demand time fence (DTF) planning horizon master production schedule (MPS) time fence available-to-promise

QUESTION 1 Review each term and match it with the appropriate definition. demand time fence (DTF) planning horizon master production schedule (MPS) time fence available-to-promise (ATP) material requirements planning (MRP) a. For a master schedule, this is normally set to cover a minimum of cumulative lead time plus time for lot sizing low-level components and time for capacity changes of primary work centers or of key suppliers. For longer-term plans, [this] must be long enough to permit any needed additions to capacity b. A set of techniques that uses bill of material data, inventory data, and the master production schedule to calculate requirements for materials. It makes recommendations to release replenishment orders for material. c. In operations, the uncommitted portion of a company's inventory and planned production maintained in the master schedule to support customer-order promising. [This] quantity is the uncommitted inventory balance in the first period and is normally calculated for each period in which an MPS receipt is scheduled. d. A line on the master schedule grid that reflects the anticipated build schedule for those items assigned to the master scheduler. The master scheduler maintains this schedule, and in turn, it becomes a set of planning numbers that drives material requirements planning. e. A policy or guideline established to note where various restrictions or changes in operating procedures take place. f. That point in time inside of which the forecast is no longer included in total demand and projected available inventory calculations; inside this point, only customer orders are considered. QUESTION 2 see the correct answers. lot size distribution requirements planning (DRP) push system pull system capacity management a. The amount of a particular item that is ordered from the plant or a supplier or issued as a standard quantity to the production process. A synonym for order quantity. b. The function of establishing, measuring, monitoring, and adjusting limits or levels of capacity in order to execute all manufacturing schedules (i.e., the production plan, master production schedule, material requirements plan, and dispatch list). c. The function of determining the need to replenish inventory at branch warehouses. A time-phased order point approach is used where the planned orders at the branch warehouse level are "exploded" via MRP logic to become gross requirements of the supplying source. d. In material control, the issuing of material according to a given schedule or issuing material to a job order at its start time. e. In material control, the withdrawal of inventory as demanded by the using operations. Material is not issued until a signal comes from the user. QUESTION 3 Review each term and match it with the appropriate definition. utilization kanban carrying cost ordering cost inventory management a. A direct labor cost incurred when a purchaser places an order. b. The cost of holding inventory, usually defined as a percentage of the dollar value of inventory per unit of time (generally one year). c. A measure (usually expressed as a percentage) of how intensively a resource is being used to produce a good or service. Compares actual time used to available time. d. It is a pull system in which work centers signal with a card that they wish to withdraw parts from feeding operations or suppliers. e. The branch of business management concerned with planning and controlling inventories

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts