Question: QUESTION 2 2.1 The table below lists the work elements (in minutes) to be performed on a manual assembly line and the precedence requirements that

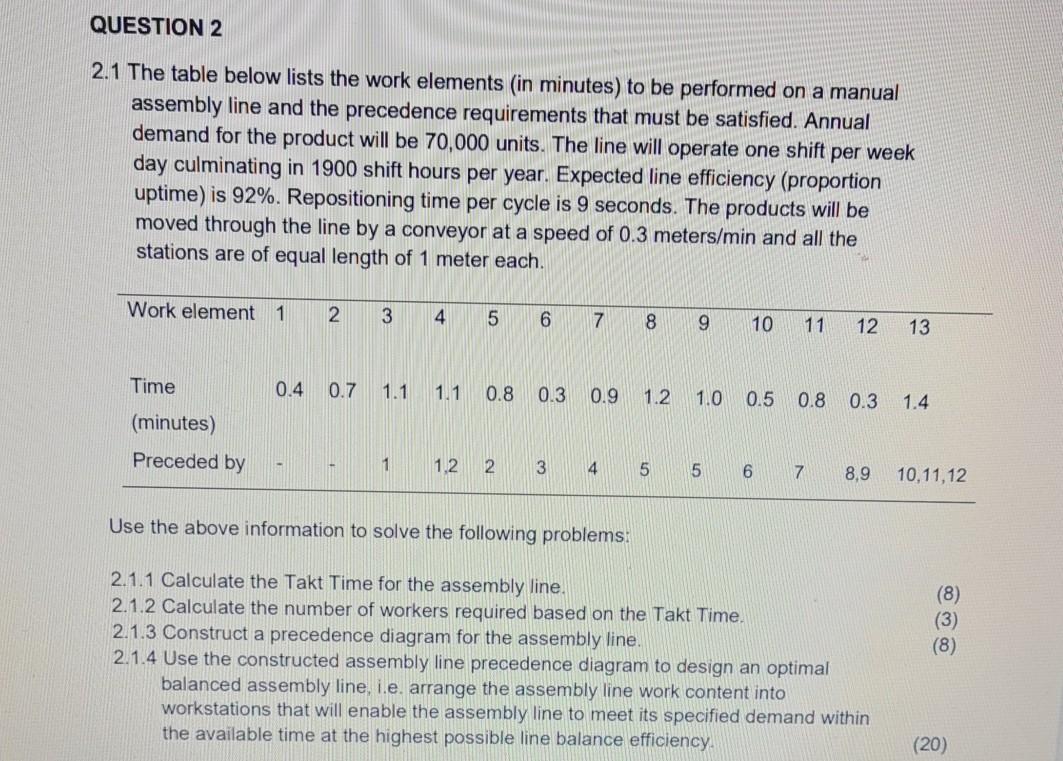

QUESTION 2 2.1 The table below lists the work elements (in minutes) to be performed on a manual assembly line and the precedence requirements that must be satisfied. Annual demand for the product will be 70,000 units. The line will operate one shift per week day culminating in 1900 shift hours per year. Expected line efficiency (proportion uptime) is 92%. Repositioning time per cycle is 9 seconds. The products will be moved through the line by a conveyor at a speed of 0.3 meters/min and all the stations are of equal length of 1 meter each. Work element 1 2 3 4 5 6 7 8 9 10 11 12 13 Time 0.4 0.7 1.1 1.1 0.8 0.3 0.9 1.2 1.0 0.5 0.8 0.3 1.4 (minutes) Preceded by 1 1.2 2 3 4 5 5 6 7 8.9 10,11,12 Use the above information to solve the following problems: (8) (3) (8) 2.1.1 Calculate the Takt Time for the assembly line. 2.1.2 Calculate the number of workers required based on the Takt Time. 2.1.3 Construct a precedence diagram for the assembly line. 2.1.4 Use the constructed assembly line precedence diagram to design an optimal balanced assembly line, i.e. arrange the assembly line work content into workstations that will enable the assembly line to meet its specified demand within the available time at the highest possible line balance efficiency. (20) 2.1.5 Presume the assembly line labourers each earn R22 per hour and calculate the labour cost per annum for the assembly line. (6) [45]

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock