Question: Question 2 - Inventory Management (30 pts) Annual demand for a product is 13,000 units; Weekly demand is 250 units with a standard deviation of

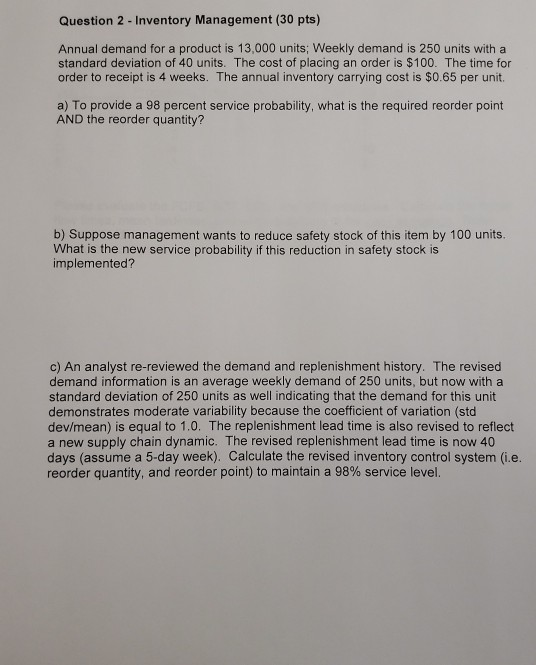

Question 2 - Inventory Management (30 pts) Annual demand for a product is 13,000 units; Weekly demand is 250 units with a standard deviation of 40 units. The cost of placing an order is $100. The time for order to receipt is 4 weeks. The annual inventory carrying cost is $0.65 per unit. a) To provide a 98 percent service probability, what is the required reorder point AND the reorder quantity? b) Suppose management wants to reduce safety stock of this item by 100 units. What is the new service probability if this reduction in safety stock is implemented? c) An analyst re-reviewed the demand and replenishment history. The revised demand information is an average weekly demand of 250 units, but now with a standard deviation of 250 units as well indicating that the demand for this unit demonstrates moderate variability because the coefficient of variation (std dev/mean) is equal to 1.0. The replenishment lead time is also revised to reflect a new supply chain dynamic. The revised replenishment lead time is now 40 days (assume a 5-day week). Calculate the revised inventory control system (i.e. reorder quantity, and reorder point) to maintain a 98% service level

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock