Question: Question 3 : SImQuick Simulation Process Flow Map for a Linear Flow Process We let time units denote minutes. The working time at each Work

Question : SImQuick Simulation

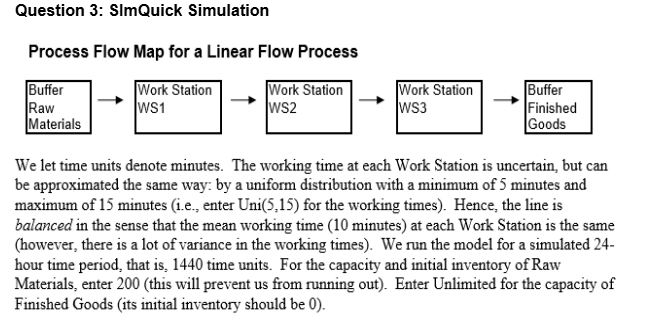

Process Flow Map for a Linear Flow Process

We let time units denote minutes. The working time at each Work Station is uncertain, but can

be approximated the same way: by a uniform distribution with a minimum of minutes and

maximum of minutes ie enter Uni for the working times Hence, the line is

balanced in the sense that the mean working time minutes at each Work Station is the same

however there is a lot of variance in the working times We run the model for a simulated

hour time period, that is time units. For the capacity and initial inventory of Raw

Materials, enter this will prevent us from running out Enter Unlimited for the capacity of

Finished Goods its initial inventory should be

SimQuick Exercise : For each of the situations a through e below, perform simulations and report the identified metrics in the table below. Note: overall mean cycle time through the process from the time it enters WS to the time it leaves WS This is computed by adding the overall mean cycle times through the internal buffers, the Buffers added between Work Stations if any and the mean working times at the Work Stations.

a Consider the SimQuick model base case as shown above. Note that the Working time for each Work Station is Uni

b Consider the original model, and change the working time at each Work Station to

Uni Note that the new working times have the same mean but a smaller variance.

c Consider the original model, using the reduced variance distribution from part b on WS

only.

d For the original model, add a Buffer between WS and WS and another Buffer between

WS and WSwith no initial inventory Set the capacity of both Buffers

e For the original model, add a Buffer between WS and WS and another Buffer between

WS and WSwith no initial inventory Set the capacity of both Buffers

begintabularllllll

hline Resultsscenarios & begintabularc

part a

base case

Uni

endtabular & begintabularc

Part b

Uni

endtabular & begintabularc

Part c

WS only

at

endtabular & begintabularl

Part d

WIP Buf

Cap

endtabular & begintabularl

Part d WIP

Buf Cap

endtabular

hline begintabularl

Throughput

Final Inventory of

FG

endtabular & & & & &

hline begintabularl

Overall mean cycle

time of system

WS through WS

endtabular & & & & &

hline begintabularl

WIP buff#

units

endtabular & & & & &

hline Time in Buff & & & & &

hline begintabularl

WIP buff

#units

endtabular & & & & &

hline Time in Buff & & & & &

hline Util WS & & & & &

hline Block WS & & & & &

hline Util WS & & & & &

hline Block WS & & & & &

hline Util WS & & & & &

hline Block WS & & & & &

hline

endtabular

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock