Question: QUESTION - Capacity Planning and Analysis Figure 1.1 shows process sequence and it respective capacity for making F104XM product. The company works 5 days a

QUESTION - Capacity Planning and Analysis

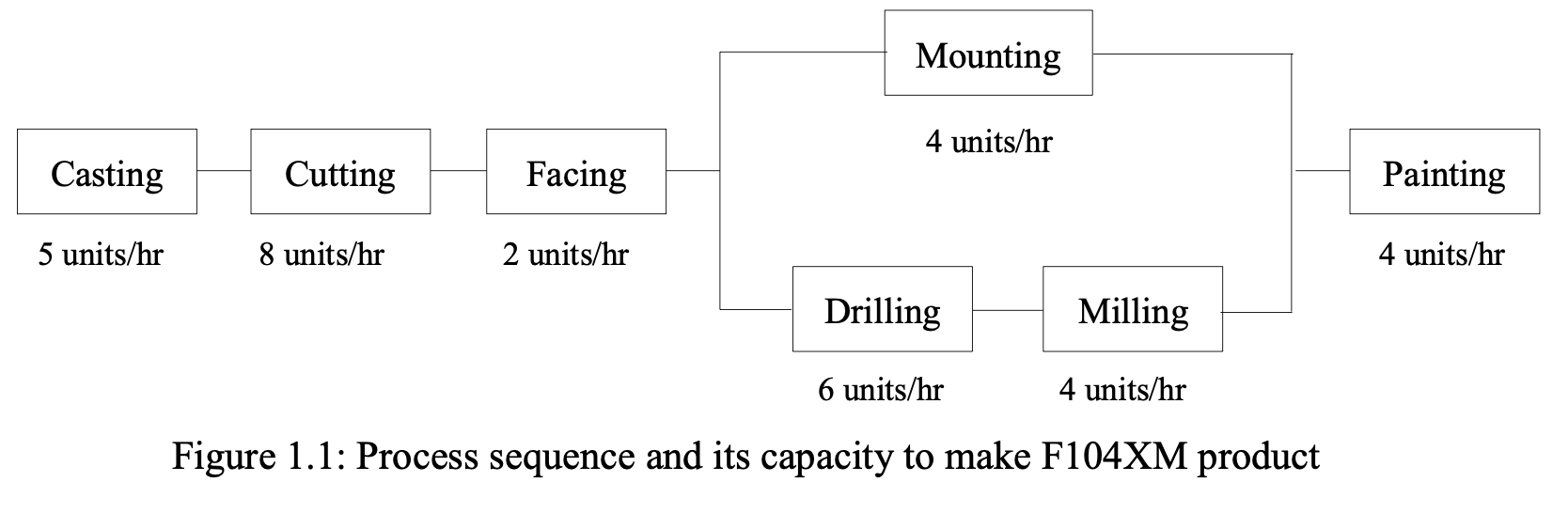

Figure 1.1 shows process sequence and it respective capacity for making F104XM product. The company works 5 days a week, single shift 8 hours per day.

i) Determine which process becomes bottleneck when making the above F104XM product. Give your reason.

ii) The capacity of the above bottleneck process is increased by adding one more parallel station. Calculate the maximum weekly capacity (effective) for the overall process.

iii) If monthly demand for the above product is 800 units, determine how much the total overtime cost the company should bear. Assume that average overtime cost is RM 25/hour and there are 4 weeks in a month.

Mounting 4 units/hr Casting Cutting Facing Painting 5 units/hr 8 units/hr 2 units/hr 4 units/hr Drilling Milling 6 units/hr 4 units/hr Figure 1.1: Process sequence and its capacity to make F104XM productStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts