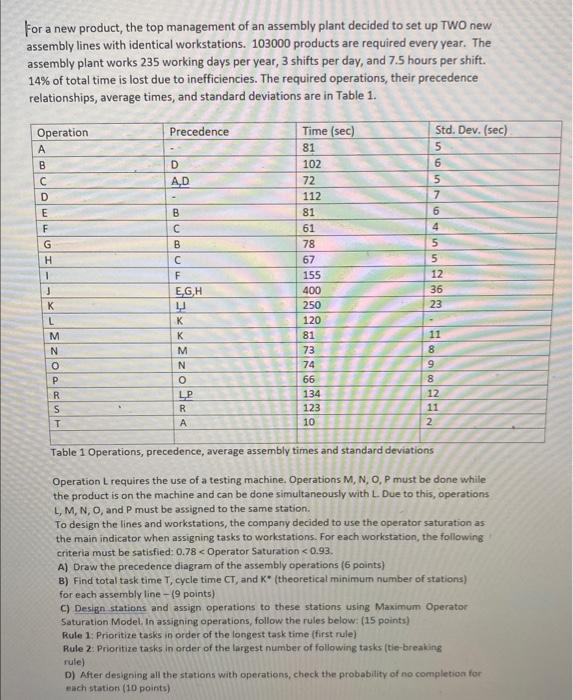

Question: Question is for my Indistrial Engineering course. For a new product, the top management of an assembly plant decided to set up TWO new assembly

Question is for my Indistrial Engineering course.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock