Question: Questions: (a) The polymer solution was run through standard nozzles and a drop size of 0.3 mm was measured. What is the drop penetration time

Questions:

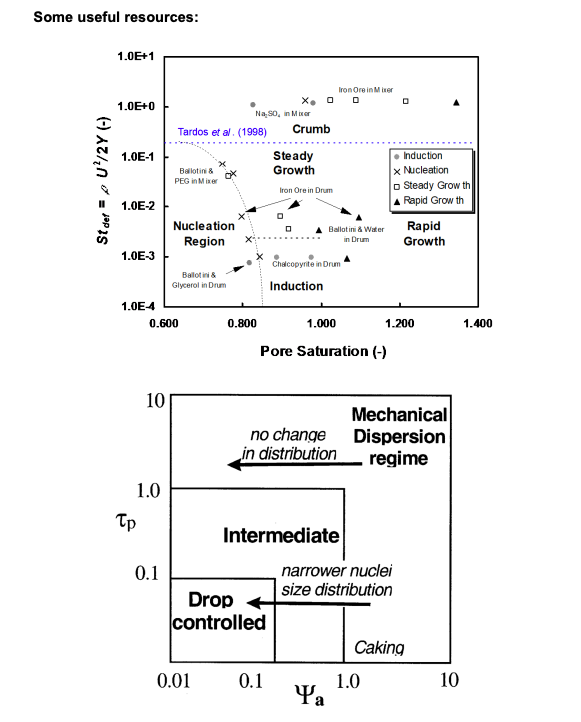

(a) The polymer solution was run through standard nozzles and a drop size of 0.3 mm was measured. What is the drop penetration time for the system?

(b) If 90% saturation is needed for granule growth, what liquid flow rate is required to be supplied to the granulator? [Assume the minimum porosity of the granules is the same as at the tapped density of the dry powder bed.]

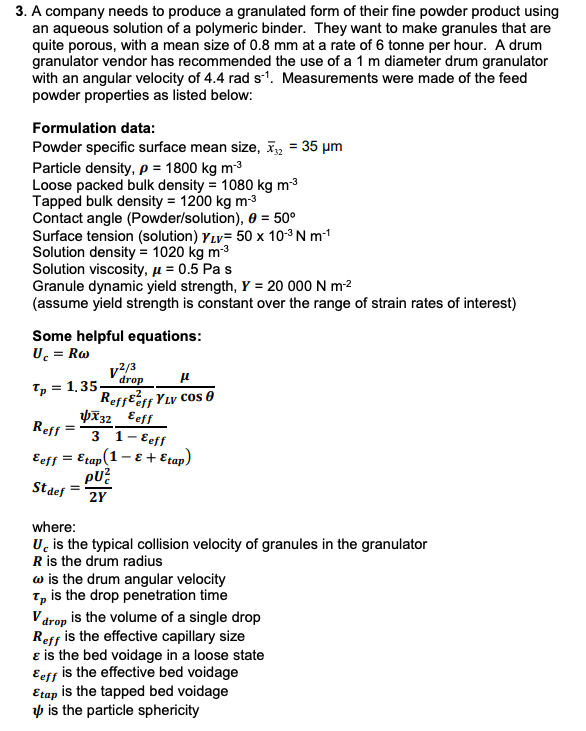

(c) What growth regime do you expect for this material in a drum granulator ie. nucleation only, induction growth, steady growth, rapid growth, crumb?

Use the following resources to solve the questions:

3. A company needs to produce a granulated form of their fine powder product using an aqueous solution of a polymeric binder. They want to make granules that are quite porous, with a mean size of 0.8mm at a rate of 6 tonne per hour. A drum granulator vendor has recommended the use of a 1m diameter drum granulator with an angular velocity of 4.4rads1. Measurements were made of the feed powder properties as listed below: Formulation data: Powder specific surface mean size, x32=35m Particle density, =1800kgm3 Loose packed bulk density =1080kgm3 Tapped bulk density =1200kgm3 Contact angle (Powder/solution), =50 Surface tension (solution) LV=50103Nm1 Solution density =1020kgm3 Solution viscosity, =0.5Pa s Granule dynamic yield strength, Y=20000Nm2 (assume yield strength is constant over the range of strain rates of interest) Some helpful equations: Uc=Rp=1.35Reffeff2Vdrop2/3LVcosReff=3x321effeffeff=tap(1+tap)Stdef=2YUc2 where: Uc is the typical collision velocity of granules in the granulator R is the drum radius is the drum angular velocity p is the drop penetration time Vdrop is the volume of a single drop Reff is the effective capillary size is the bed voidage in a loose state eff is the effective bed voidage tap is the tapped bed voidage is the particle sphericity Some useful resources

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts