Question: Read and answer the question Identify the strategic issues facing craft brewers in 2020. What effects may these issues have on the industry? the production

Read and answer the question

Identify the strategic issues facing craft brewers in 2020. What effects may these issues have on the industry?

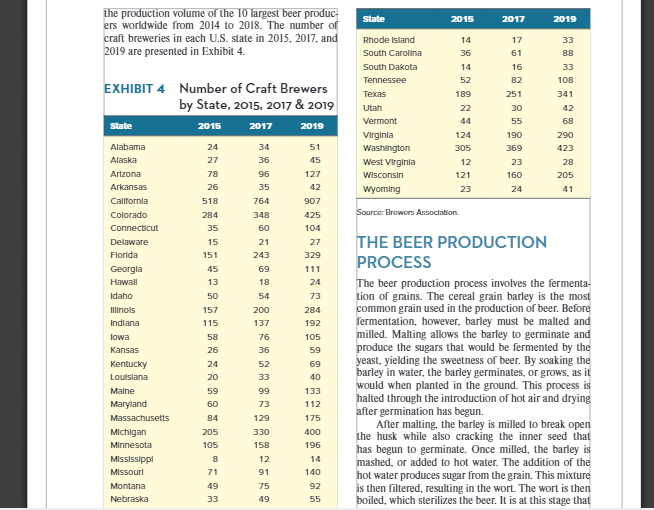

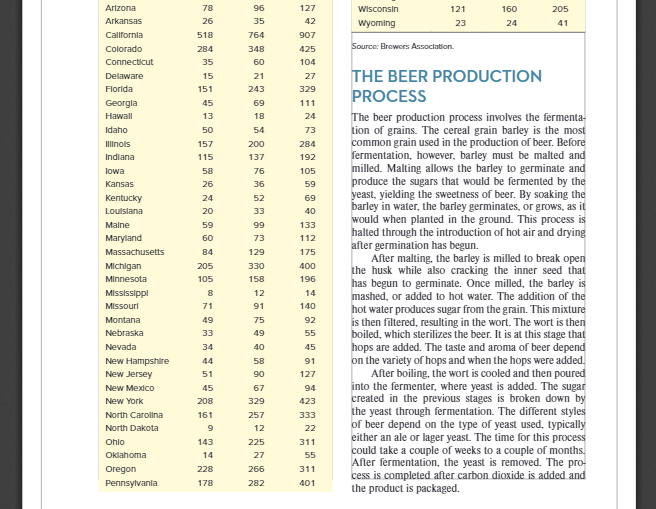

the production volume of the 10 largest beer produc- State 2015 2017 2019 ers worldwide from 2014 to 2018. The number of craft breweries in each U.S. state in 2015, 2017, and 2019 are presented in Exhibit 4. Rhode Island 14 17 33 South Carolina 36 61 88 South Dakota 14 16 33 Tennessee 52 82 108 Texas 189 251 EXHIBIT 4 Number of Craft Brewers by State, 2015, 2017 & 2019 341 Utah 22 30 42 Vermont 44 55 6B State 2015 2017 2019 124 190 290 Alabama 24 34 51 305 369 423 Virginia Washington West Virginia Wisconsin Alaska 27 36 45 12 23 28 Arizona 78 96 127 121 160 205 Arkansas 26 35 42 Wyoming 23 24 41 California 518 764 907 Colorado 284 348 425 Source: Browers Association Connecticut 35 60 104 Delaware 15 21 27 Florida 151 243 329 Georgia 45 69 111 Hawall 13 18 24 Idaho 50 54 73 Illinois 157 200 284 Indiana 115 137 192 lowa 58 wn%8B&wm89ng 76 105 Kansas 26 36 59 Kentucky 24 52 69 THE BEER PRODUCTION PROCESS The beer production process involves the fermenta- tion of grains. The cereal grain barley is the most common grain used in the production of beer. Before fermentation, however, barley must be malted and milled. Malting allows the barley to germinate and produce the sugars that would be fermented by the yeast, yielding the sweetness of beer. By soaking the barley in water, the barley germinates, or grows, as it would when planted in the ground. This process is halted through the introduction of hot air and drying after germination has begun. After malting, the barley is milled to break open the husk while also cracking the inner seed that has begun to germinate. Once milled, the barley is mashed, or added to hot water. The addition of the hot water produces sugar from the grain. This mixture is then filtered, resulting in the wort. The wort is then boiled, which sterilizes the beer. It is at this stage that Louisiana 20 33 40 Maine 59 99 133 Maryland 60 73 112 Massachusetts 84 129 175 Michigan 205 330 400 Minnesota 105 158 196 Mississippi 8 12 14 Missouri 71 91 140 Montana 49 75 92 Nebraska 33 49 55 Arizona 78 96 127 Wisconsin 121 160 205 Arkansas 26 35 42 Wyoming 23 24 41 California 518 764 907 Colorado 284 348 Source: Browers Association 425 Connecticut 35 60 104 Delaware 15 21 27 Florida 151 243 329 Georgia 45 69 111 Hawall 13 18 24 Idaho 50 54 73 Illinois 157 200 284 Indiana 115 137 192 lowa 58 76 105 Kansas 26 36 59 24 52 69 Kentucky Louisiana 20 33 40 Maine 59 99 133 Maryland 60 73 112 Massachusetts 84 129 175 Michigan 205 330 400 Minnesota 105 158 196 THE BEER PRODUCTION PROCESS The beer production process involves the fermenta- tion of grains. The cereal grain barley is the most common grain used in the production of beer. Before fermentation, however, barley must be malted and milled. Malting allows the barley to germinate and produce the sugars that would be fermented by the yeast, yielding the sweetness of beer. By soaking the barley in water, the barley germinates, or grows, as it would when planted in the ground. This process is halted through the introduction of hot air and drying after germination has begun. After malting, the barley is milled to break open the husk while also cracking the inner seed that has begun to germinate. Once milled, the barley is mashed, or added to hot water. The addition of the hot water produces sugar from the grain. This mixture is then filtered, resulting in the wort. The wort is then boiled, which sterilizes the beer. It is at this stage that hops are added. The taste and aroma of beer depend on the variety of hops and when the hops were added. After boiling, the wort is cooled and then poured into the fermenter, where yeast is added. The sugar created in the previous stages is broken down by the yeast through fermentation. The different styles of beer depend on the type of yeast used, typically an ale or lager yeast. The time this process could take a couple of weeks to a couple of months. After fermentation, the yeast is removed. The pro- cess is completed after carbon dioxide is added and the product is packaged. Mississippi 8 12 14 Missouri 71 91 140 Montana 49 75 92 Nebraska 33 49 55 Nevada 34 40 45 44 58 91 New Hampshire New Jersey 51 90 127 New Mexico 45 67 94 New York 208 329 423 North Carolina 161 257 333 North Dakota 9 12 22 eiti Ohio 143 225 311 Oklahoma 14 27 55 Oregon 228 266 311 Pennsylvania 178 282 401 on volume sold to the consumer. Beer is a varied and differentiated product, with Distribution could be distinguished through over 70 styles in 15 categories. Each style is depen- direct sales (or self-distribution), and two-tier and dent on a number of variables. These variables are three-tier systems. Regulations permitting direct sales controlled by the brewer through the process, and allow the brewery to sell directly to the consumer. could include the origin of raw materials, approach to Growers, bottle sales, and taprooms were all forms fermentation, and yeast used. For example, Guinness of direct, or retail sales. There were usually require referenced on its website how barley purchased by ments concerning direct sales, including limitations the brewer was not only grown locally, but was also toasted specifically after malting, lending to its char Even where self-distribution was legal, the legal acteristic taste and color. As another example of dif volumes could be very small and limited. Very few ferentiation through raw materials, wheat beers, such brewers were exempt from distributing through as German-style heleweizen, are brewed with a mini wholesalers, referred to as a three-tier distribution mum of 50 percent wheat instead of barley grain. system. And often to be operationally viable, brewers need access to this distribution system to generate revenue. In a three-tier system, the brewery must first DEVELOPMENT OF sell to a wholesaler-the liquor or beer distributor. MICROBREWERIES AND This distributor then sells to the retailer, who then ultimately sells to the consumer. ECONOMICS OF SCALE This distribution structure, however, had ramifi- Although learning the art of brewing takes time. cations for the consumer, as much of what was avail beer production lends itself to scalability and vari able at retail outlets and restaurants were impacted by ety. For example, an amateur, or home brewer, could the distributor. This was further impacted by whether brew beer for home consumption. There had been a la brewery bottles or cans its beer or distributes significant increase in the interest in homebrewing, through kegs. While restaurants and bars could carry with over 1 million people pursuing the hobby in kegs, retail shelves at a local liquor store needed to 2017." It was also not uncommon for a home brewer have cans and bottles, as a relatively small number of to venture into entrepreneurship and begin brewing consumers could accommodate kegs for home use. for commercial sales. However, beer production was Thus, there may only be a few liquor stores or res highly labor intensive with much of the work done taurants where a consumer may find a locally-brewed by hand. A certain level of production volume was necessary to achieve breakeven and make the micro- on-premise sales, distribution and exposure to con- brewery a successful commercial operation. sumers could represent a barrier for breweries, espe- A small nanobrewery may brew a variety of fla- cially those that were small or new. vor experiences and compete in niche markets, while The Alcohol and Tobacco Tax and Trade Bureau the macrobrewery may focus on economies of scale (TTB) was the main federal agency for regulating this and mass produce one style of beer. Both may attract industry. As another example of regulations, brewer consumers across segments and were attributed to ies were required to have labels for beers approved by the easily scalable yet highly variable process of brew the federal government, ensuring they meet advertis beer. In states that do not allow self-distribution or beer. In states that do not allow self-distribution or revenue. In a three-tier system, the brewery must first DEVELOPMENT OF sell to a wholesaler-the liquor or beer distributor. MICROBREWERIES AND This distributor then sells to the retailer, who then ultimately sells to the consumer. ECONOMICS OF SCALE This distribution structure, however, had ramifi- Although learning the art of brewing takes time, cations for the consumer, as much of what was avail beer production lends itself to scalability and vari able at retail outlets and restaurants were impacted by ety. For example, an amateur, or home brewer, could the distributor. This was further impacted by whether brew beer for home consumption. There had been a a brewery bottles or cans its beer or distributes significant increase in the interest in homebrewing, through kegs. While restaurants and bars could carry with over 1 million people pursuing the hobby in kegs, retail shelves at a local liquor store needed to 2017." It was also not uncommon for a home brewer have cans and bottles, as a relatively small number of consumers could accommodate kegs for home use. to venture into entrepreneurship and begin brewing for commercial sales. However, beer production was Thus, there may only be a few liquor stores or res- highly labor intensive with much of the work done taurants where a consumer may find a locally-brewed by hand. A certain level of production volume was necessary to achieve breakeven and make the micro on-premise sales, distribution and exposure to con- brewery a successful commercial operation. sumers could represent a barrier for breweries, espe- A small nanobrewery may brew a variety of fla- cially those that were small or new. vor experiences and compete in niche markets, while The Alcohol and Tobacco Tax and Trade Bureau the macrobrewery may focus on economies of scale (TTB) was the main federal agency for regulating this and mass produce one style of beer. Both may attract industry. As another example of regulations, brewer- consumers across segments and were attributed to ies were required to have labels for beers approved by the easily scalable yet highly variable process of brew the federal government, ensuring they meet advertis ing beer. In contrast, a global producer such as AB ing guidelines. In some instances, the TTB may need InBev could produce beer for millions of consumers to approve the formula used for brewing the specific worldwide with factory-automated processes. beer prior to the label receiving approval. Given the approval process, and the growth of craft brewer- ies, the length of time this takes could reach several LEGAL ENVIRONMENT OF months. For a small, microbrewery first starting, the BREWERIES delay in sales could potentially impact cash flow. Employment law was another area impacting As beer is an alcoholic beverage, the industry is sub- breweries. The Affordable Care Act (ACA) and ject to much regulation. Further, these regulations changes to the Fair Labor Standards Act (FLSA) can vary by state and municipality. One such regula- greatly affected labor cost in the industry. Where the tion was regarding sales and distribution. ACA mandated health care coverage by employersStep by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts