Question: Read the case below then answer the following 7 Questions 1. Introduction Companies are continually striving to increase productivity and output of their operations Lean

Read the case below then answer the following 7 Questions 1. Introduction Companies are continually striving to increase productivity and output of their operations Lean has been originally created and defined as the process of eliminating waste Toyota with the support a system to reduce or eliminate waste and non-value added activities from various processes. Value smarts is all the steps. both value added and non-value added required taking a product or service from raw material to the customer. a value stream Mapping is visualization and streamlines work processes using the tools rid techniques of Lean Manufacturing. VSM help to identify. demonstrate and decrease waste n the processes. Waste being any activity that does not add value to the final Product VS.."' serve as a blue print for lean manufacturing. From this study we are focusing on SME tat level or door-to-door VSM.

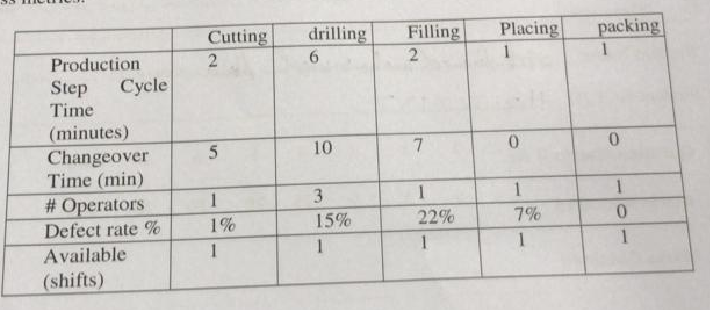

Current State Value Stream Map Abdin Company is struggling with customers' complaints on waiting time of delivery. The metrics description of current process state is: Pre manufacturing metrics: Order entry time = I day Raw material ordering = 30 minutes Raw material delivery time = 3 days Incoming inspection time = 8 hours Post manufacturing: Delivery time = 4 hours Process metrics:

you must know that there is a daily demand of 700 pieces with the following arrangement. lours per shift: 8 break minutes per shift: 30 days per week: 5

Question 1: Analyze the role of Heijunka as a tool used to level production?

Question 2: what do you mean by paced withdrawal and discussed whether you will apply the paced withdrawal method to improve the VSM of abdin industrial? justify your answer

Question 3:Analyze one value added activities and one nonvalue added activities for Abdin Industry.

Question 4: Map the current state for Abdin industry in details. to draw the map?

Question 5: Find the following for the chosen value stream from Abdin Industry:

a- Total cycle time b- Total lead time c- Total changeover time d- Uptime for each operation e- Calculate the capacity for each process f- Calculate number of operators needed

Question 6: Describe the effects of applying value stream management on the following factors: Value-added ratio, Overall equipment effectiveness, Factory floor space, People.

Question 7: a- You recently started a job in Abdin Industry. Since you have a degree in Quality Management, the president of the company appointed you as a value stream champion to improve the company's value stream efficiency. Determine when you need to control upstream production and explain how you will perform it if needed. b- Discuss in details the main tools you will use for improving the demand stage of Abdin Industry.

\begin{tabular}{|l|l|l|l|l|l|} \hline & Cutting & drilling & Filling & Placing & packing \\ \hline ProductionStepCycleTime(minutes) & 2 & 6 & 2 & 1 & 1 \\ \hline ChangeoverTime(min) & 5 & 10 & 7 & 0 & 0 \\ \hline \# Operators & 1 & 3 & 1 & 1 & 1 \\ \hline Defect rate \% & 1% & 15% & 22% & 7% & 0 \\ \hline Available(shifts) & 1 & 1 & 1 & 1 & 1 \\ \hline \end{tabular}

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts