Question: Regular Capacity = 425 Overtime Capacity = 310 Subcontractor Capacity = 285 2. A company producing chips for laptop computers aims to meet demand of

Regular Capacity = 425 Overtime Capacity = 310 Subcontractor Capacity = 285

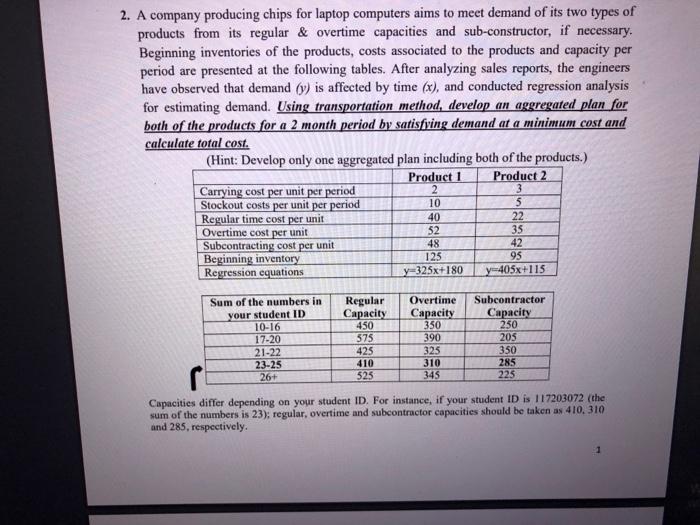

2. A company producing chips for laptop computers aims to meet demand of its two types of products from its regular & overtime capacities and sub-constructor, if necessary. Beginning inventories of the products, costs associated to the products and capacity per period are presented at the following tables. After analyzing sales reports, the engineers have observed that demand (y) is affected by time (x), and conducted regression analysis for estimating demand. Using transportation method, develop an aggregated plan for both of the products for a 2 month period by satisfying demand at a minimum cost and calculate total cost (Hint: Develop only one aggregated plan including both of the products.) Product 1 Product 2 Carrying cost per unit per period 2 3 Stockout costs per unit per period Regular time cost per unit 22 Overtime cost per unit 35 Subcontracting cost per unit 42 Beginning inventory 125 Regression equations y-325x+180 y 405x+115 5 10 40 52 48 95 Regular Capacity 450 Sum of the numbers in your student ID 10-16 17-20 21-22 23-25 26+ Overtime Capacity 350 390 325 310 $75 Subcontractor Capacity 250 205 350 285 225 425 410 523 Capacities differ depending on your student ID. For instance, if your student ID is 117203072 (the sum of the numbers is 23), regular, overtime and subcontractor capacities should be taken as 410, 310 and 285, respectively, 1 2. A company producing chips for laptop computers aims to meet demand of its two types of products from its regular & overtime capacities and sub-constructor, if necessary. Beginning inventories of the products, costs associated to the products and capacity per period are presented at the following tables. After analyzing sales reports, the engineers have observed that demand (y) is affected by time (x), and conducted regression analysis for estimating demand. Using transportation method, develop an aggregated plan for both of the products for a 2 month period by satisfying demand at a minimum cost and calculate total cost (Hint: Develop only one aggregated plan including both of the products.) Product 1 Product 2 Carrying cost per unit per period 2 3 Stockout costs per unit per period Regular time cost per unit 22 Overtime cost per unit 35 Subcontracting cost per unit 42 Beginning inventory 125 Regression equations y-325x+180 y 405x+115 5 10 40 52 48 95 Regular Capacity 450 Sum of the numbers in your student ID 10-16 17-20 21-22 23-25 26+ Overtime Capacity 350 390 325 310 $75 Subcontractor Capacity 250 205 350 285 225 425 410 523 Capacities differ depending on your student ID. For instance, if your student ID is 117203072 (the sum of the numbers is 23), regular, overtime and subcontractor capacities should be taken as 410, 310 and 285, respectively, 1

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock