Question: Repeat the example question in the lecture Synthesis of Metals regarding with the reduction of Cr2O3 to Cr at 1400 C (1673 K) in a

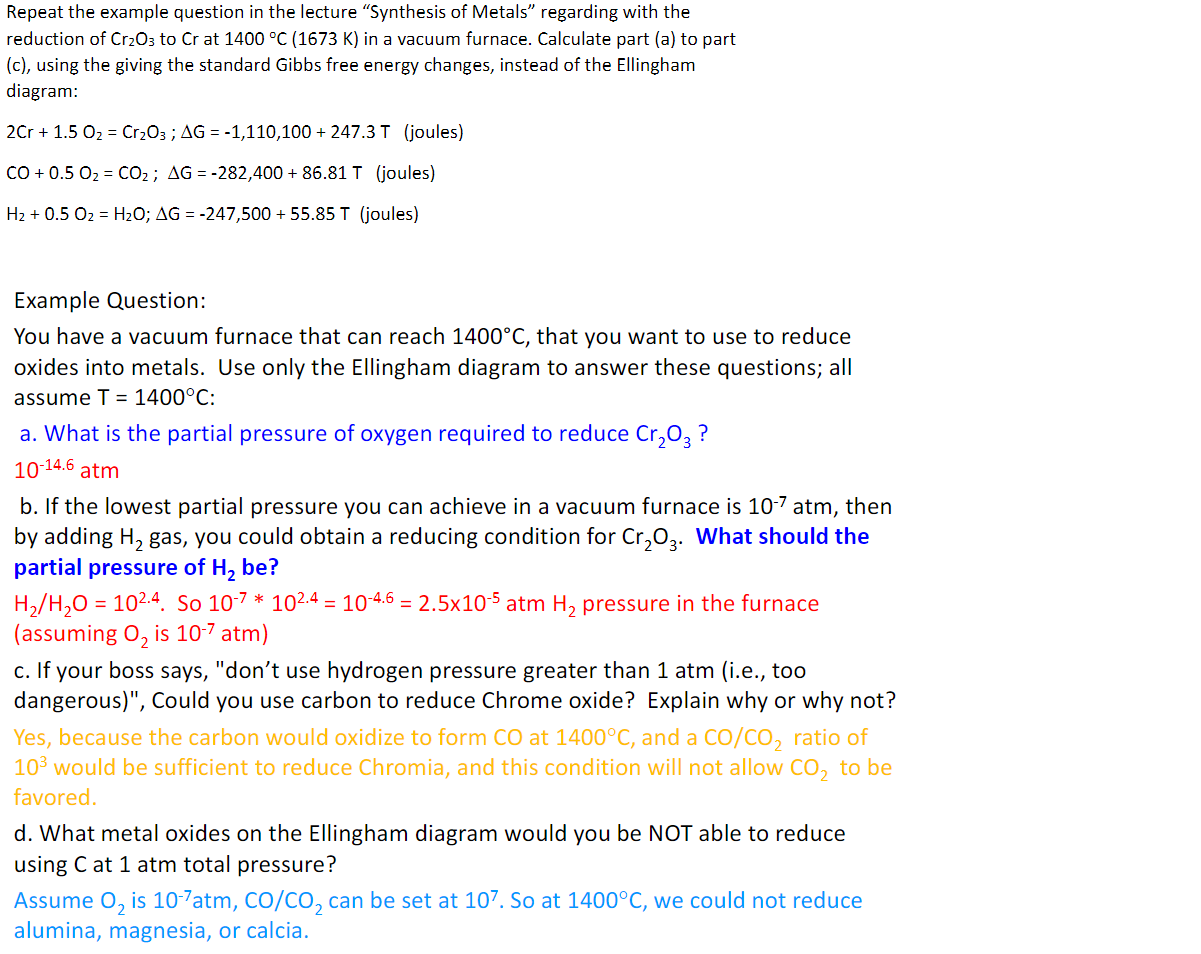

Repeat the example question in the lecture Synthesis of Metals regarding with the reduction of Cr2O3 to Cr at 1400 C (1673 K) in a vacuum furnace. Calculate part (a) to part (c), using the giving the standard Gibbs free energy changes, instead of the Ellingham diagram: 2Cr + 1.5 Oz = Cr2O3 ; AG = -1,110,100 + 247.31 (joules) CO+ 0.5 O2 = CO2; AG = -282,400 + 86.81 T (joules) H2 + 0.5 O2 = H20; AG = -247,500 + 55.85 T (joules) Example Question: You have a vacuum furnace that can reach 1400C, that you want to use to reduce oxides into metals. Use only the Ellingham diagram to answer these questions; all assume T = 1400C: a. What is the partial pressure of oxygen required to reduce Cr2O3 ? 10-14.6 atm b. If the lowest partial pressure you can achieve in a vacuum furnace is 10-7 atm, then by adding Hy gas, you could obtain a reducing condition for Cr2O3. What should the partial pressure of Hy be? H2/H20 = 102.4. So 10-7* 102.4 = 10-4.6 = 2.5x10-5 atm H2 pressure in the furnace (assuming O is 10-7 atm) c. If your boss says, "don't use hydrogen pressure greater than 1 atm (i.e., too dangerous)", Could you use carbon to reduce Chrome oxide? Explain why or why not? Yes, because the carbon would oxidize to form CO at 1400C, and a co/CO2 ratio of 103 would be sufficient to reduce Chromia, and this condition will not allow CO, to be favored. d. What metal oxides on the Ellingham diagram would you be NOT able to reduce using C at 1 atm total pressure? Assume O is 10-7atm, co/co, can be set at 107. So at 1400C, we could not reduce alumina, magnesia, or calcia

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts