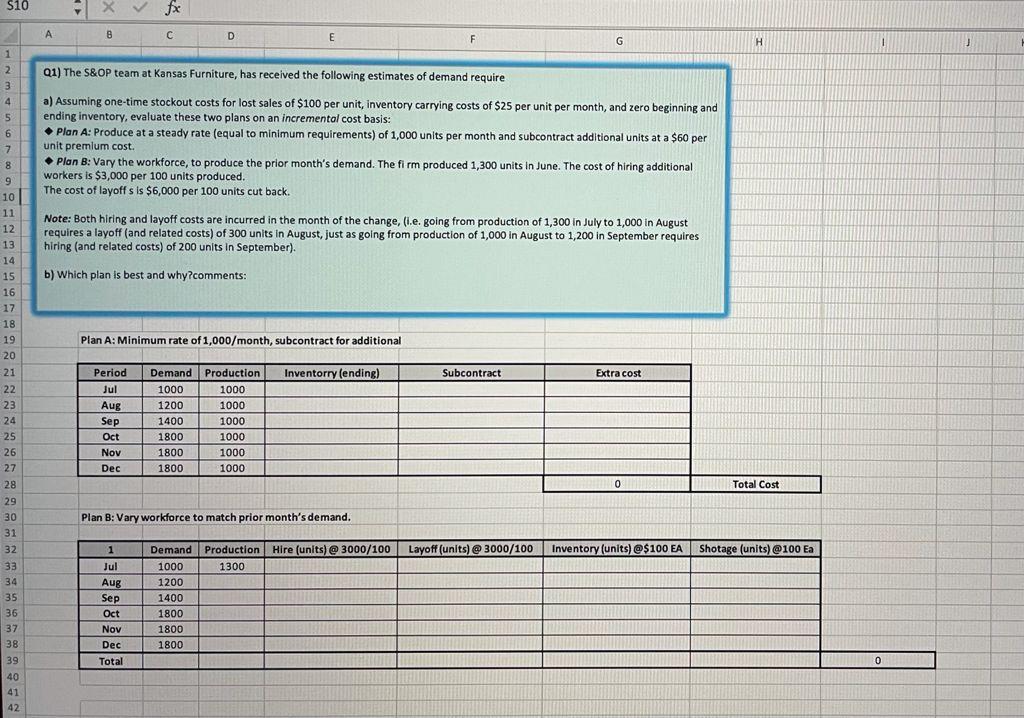

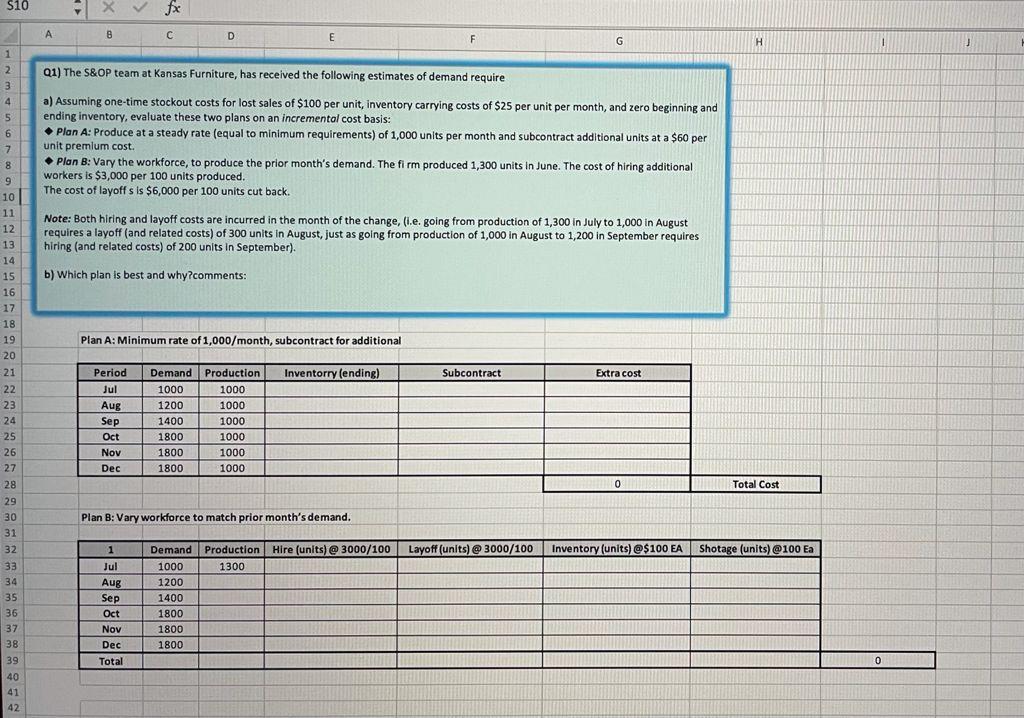

Question: S10 fx A 8 D E G H 1 1 Q1) The S&OP team at Kansas Furniture, has received the following estimates of demand require

S10 fx A 8 D E G H 1 1 Q1) The S&OP team at Kansas Furniture, has received the following estimates of demand require a) Assuming one-time stockout costs for lost sales of $100 per unit, inventory carrying costs of $25 per unit per month, and zero beginning and ending inventory, evaluate these two plans on an incremental cost basis: Plan A: Produce at a steady rate (equal to minimum requirements) of 1,000 units per month and subcontract additional units at a $60 per unit premium cost. Plan B: Vary the workforce, to produce the prior month's demand. The firm produced 1,300 units in June. The cost of hiring additional workers is $3,000 per 100 units produced. The cost of layoffs is $6,000 per 100 units cut back. 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 Note: Both hiring and layoff costs are incurred in the month of the change, (i.e. going from production of 1,300 in July to 1,000 in August requires a layoff (and related costs) of 300 units in August, just as going from production of 1,000 in August to 1,200 in September requires hiring and related costs) of 200 units in September). b) Which plan is best and why?comments: Plan A: Minimum rate of 1,000/month, subcontract for additional Inventorry (ending) Subcontract Extra cost Period Jul Aug Sep Oct Nov Dec Demand Production 1000 1000 1200 1000 1400 1000 1800 1000 1800 1000 1800 1000 26 27 29 28 0 Total Cost Plan B: Vary workforce to match prior month's demand. Layoff (units) @3000/100 Inventory (units) $100 EA Shotage (units) @100 Ea 29 an 30 23 31 32 33 34 ar 35 36 26 37 38 20 39 40 41 42 Jul Aug Sep Oct Nov Dec Total Demand Production Hire (units) @3000/100 1000 1300 1200 1400 1800 1800 1800 0 S10 fx A 8 D E G H 1 1 Q1) The S&OP team at Kansas Furniture, has received the following estimates of demand require a) Assuming one-time stockout costs for lost sales of $100 per unit, inventory carrying costs of $25 per unit per month, and zero beginning and ending inventory, evaluate these two plans on an incremental cost basis: Plan A: Produce at a steady rate (equal to minimum requirements) of 1,000 units per month and subcontract additional units at a $60 per unit premium cost. Plan B: Vary the workforce, to produce the prior month's demand. The firm produced 1,300 units in June. The cost of hiring additional workers is $3,000 per 100 units produced. The cost of layoffs is $6,000 per 100 units cut back. 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 Note: Both hiring and layoff costs are incurred in the month of the change, (i.e. going from production of 1,300 in July to 1,000 in August requires a layoff (and related costs) of 300 units in August, just as going from production of 1,000 in August to 1,200 in September requires hiring and related costs) of 200 units in September). b) Which plan is best and why?comments: Plan A: Minimum rate of 1,000/month, subcontract for additional Inventorry (ending) Subcontract Extra cost Period Jul Aug Sep Oct Nov Dec Demand Production 1000 1000 1200 1000 1400 1000 1800 1000 1800 1000 1800 1000 26 27 29 28 0 Total Cost Plan B: Vary workforce to match prior month's demand. Layoff (units) @3000/100 Inventory (units) $100 EA Shotage (units) @100 Ea 29 an 30 23 31 32 33 34 ar 35 36 26 37 38 20 39 40 41 42 Jul Aug Sep Oct Nov Dec Total Demand Production Hire (units) @3000/100 1000 1300 1200 1400 1800 1800 1800 0