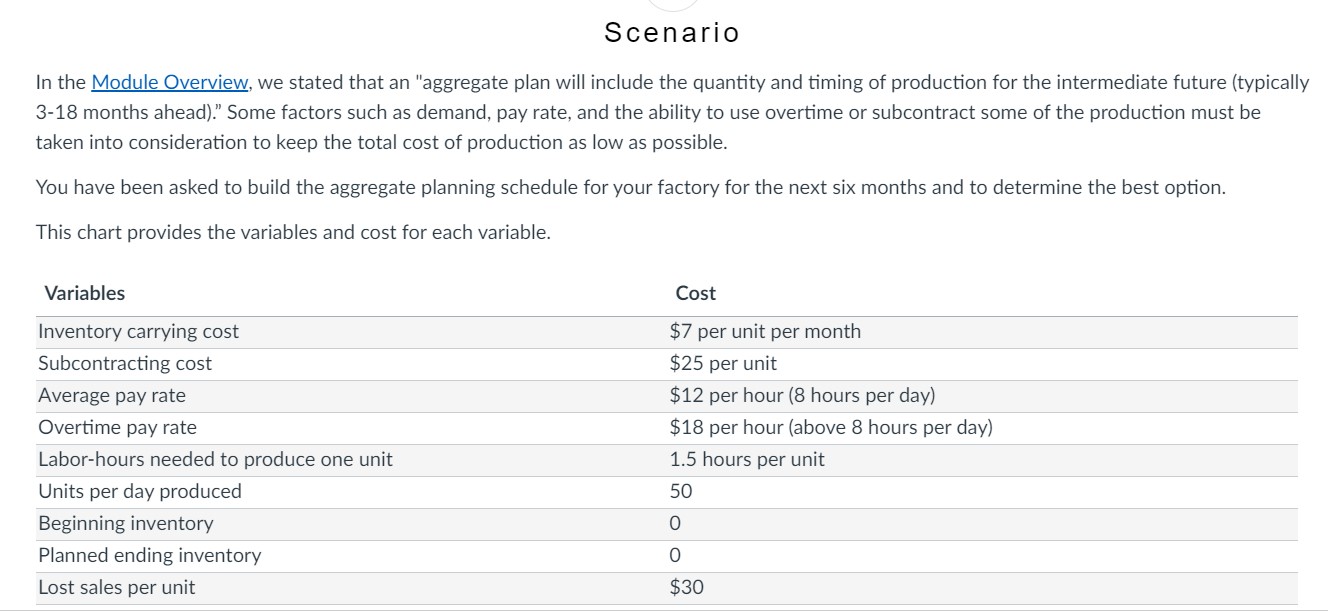

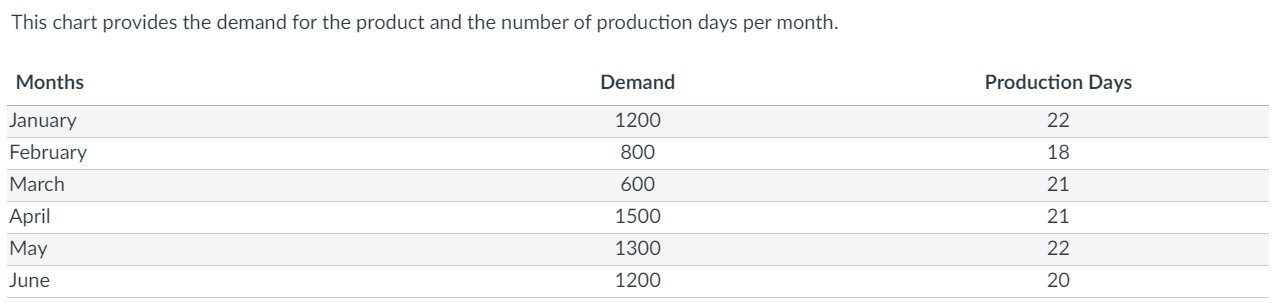

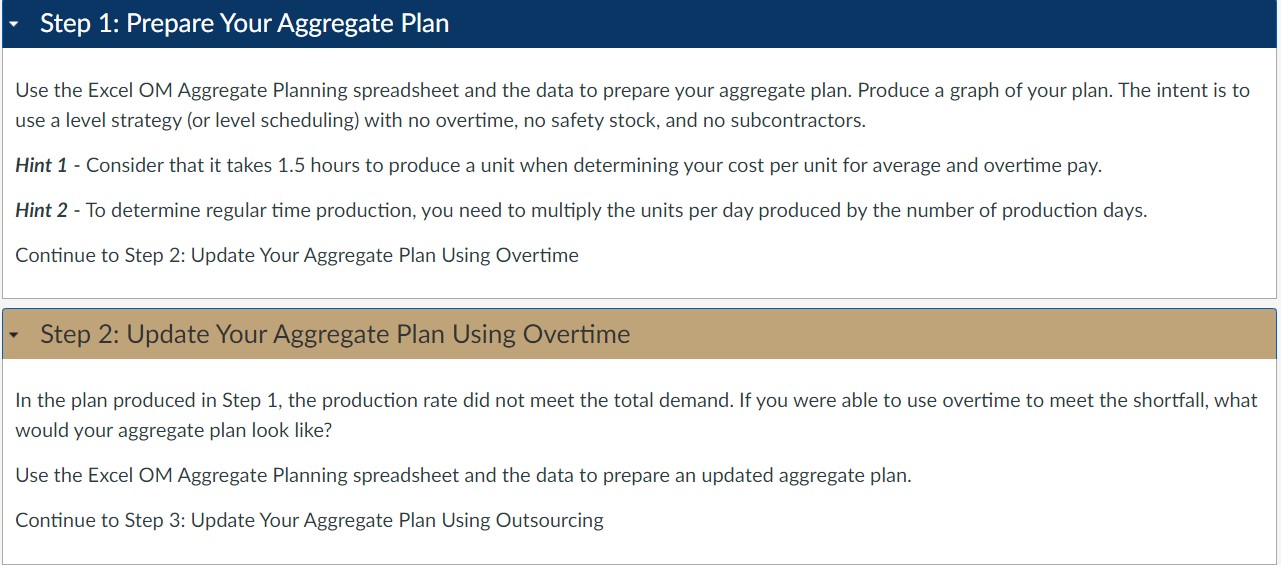

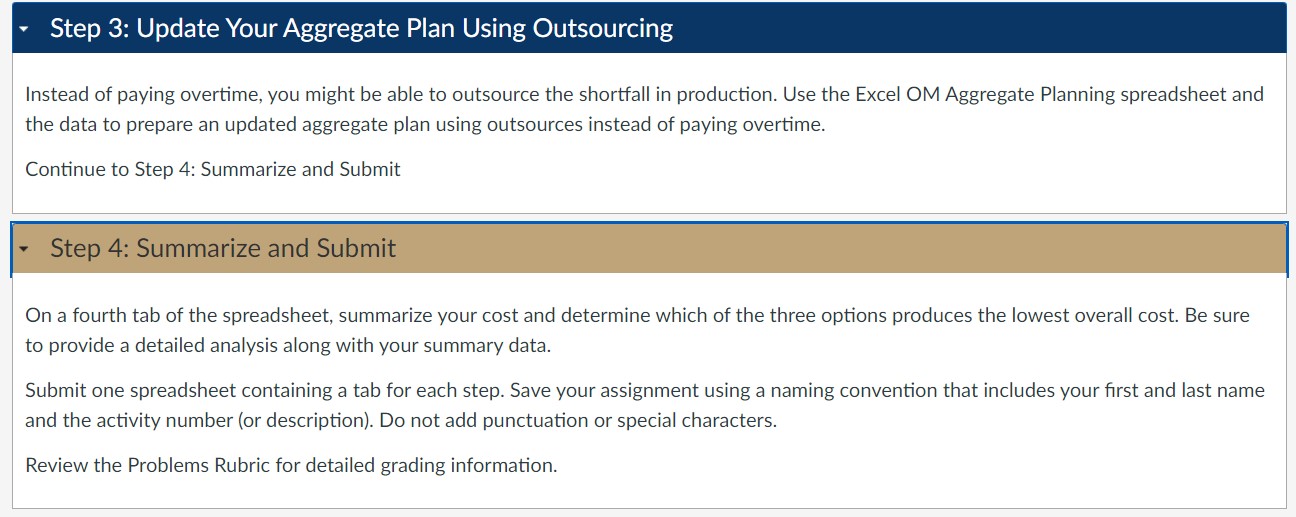

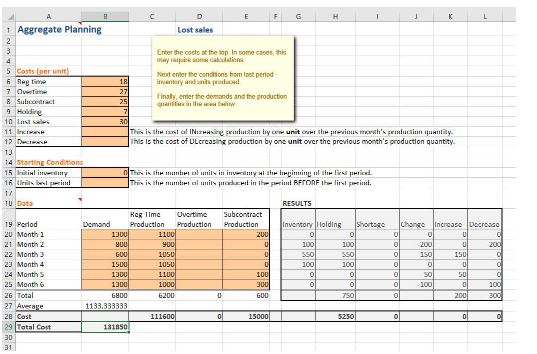

Question: Scenario In the Module Overview, we stated that an aggregate plan will include the quantity and timing of production for the intermediate future (typically 3-18

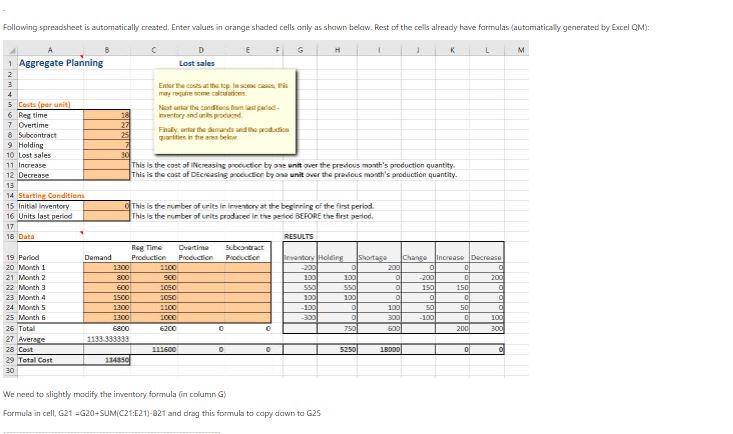

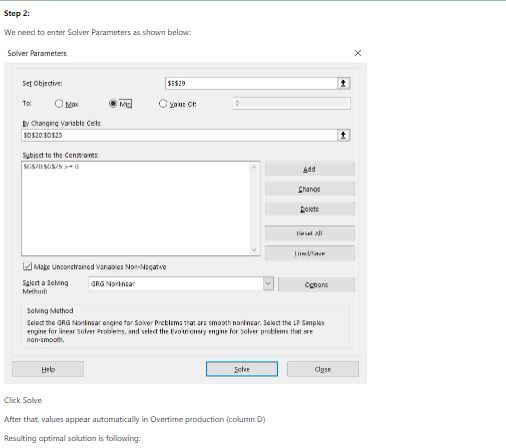

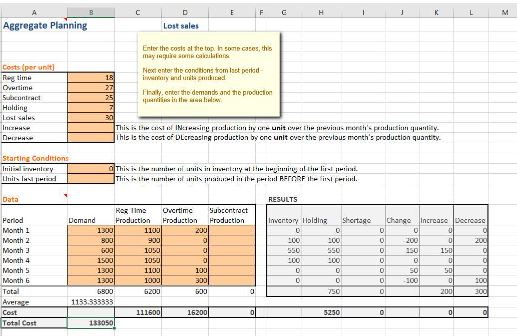

Step by Step Solution

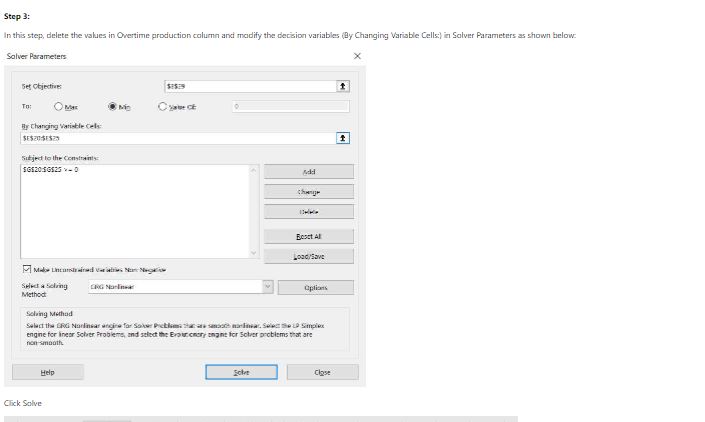

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts