Question: In the Module Overview, we stated that an aggregate plan will include the quantity and timing of production for the intermediate future (typically 3-18 months

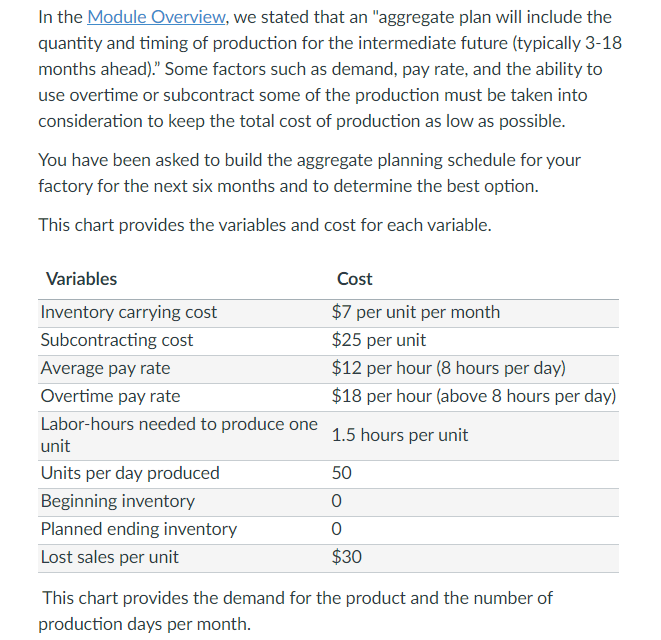

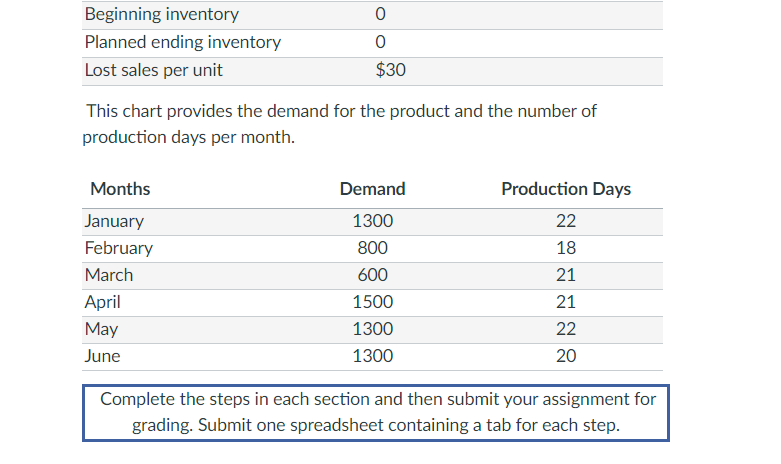

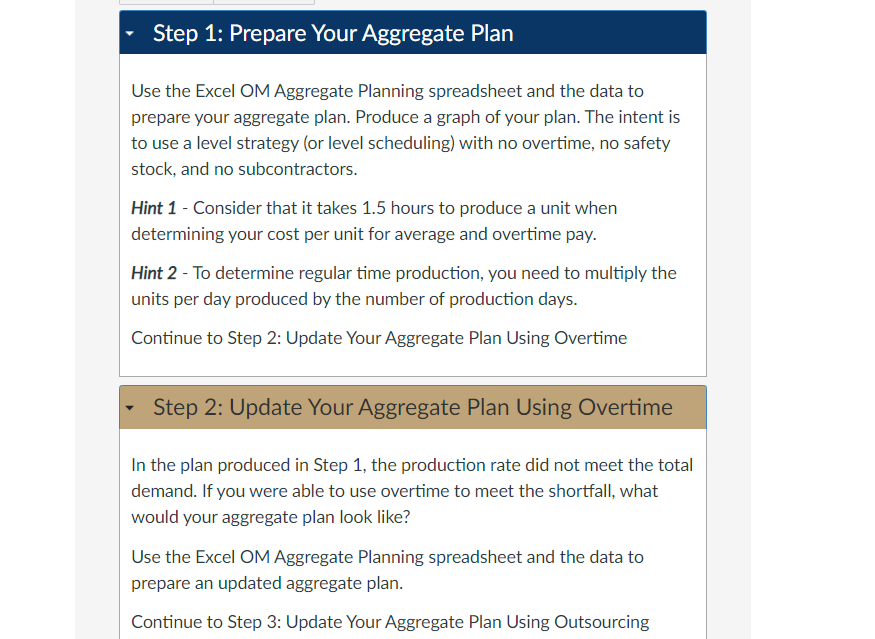

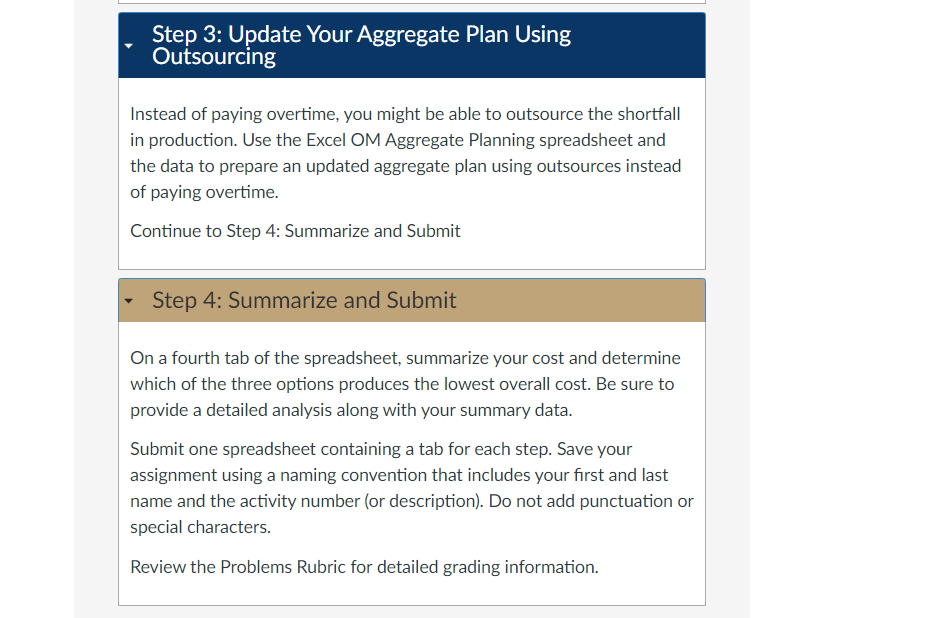

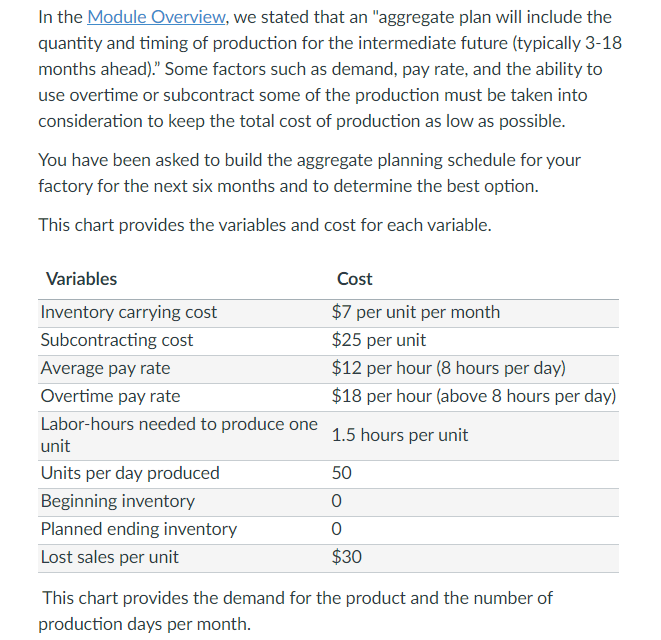

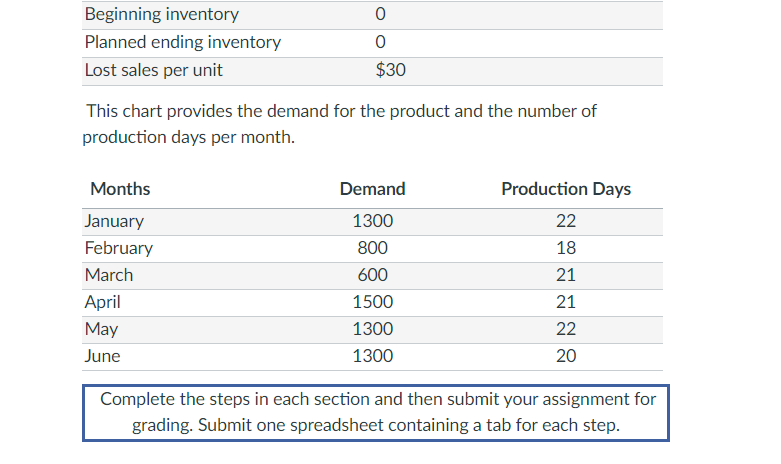

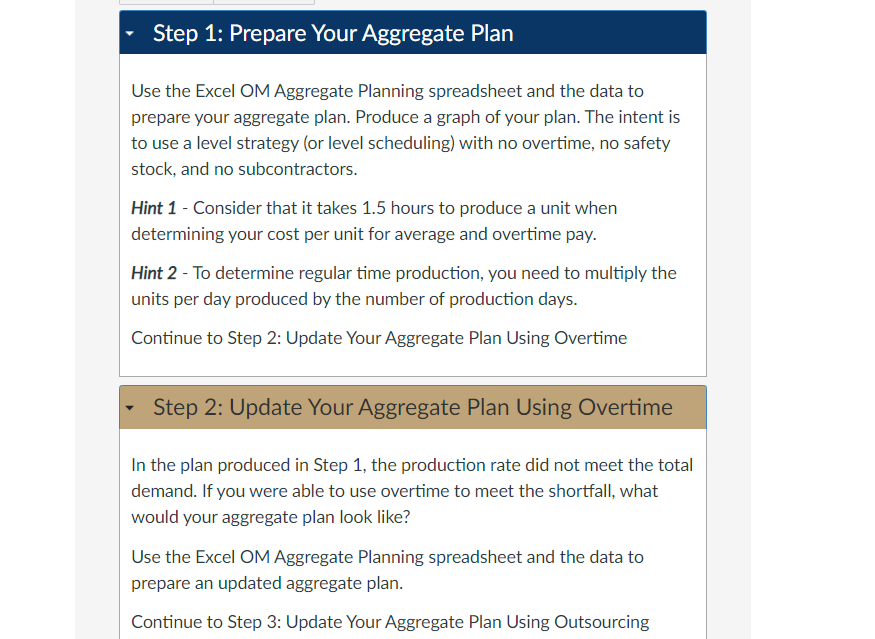

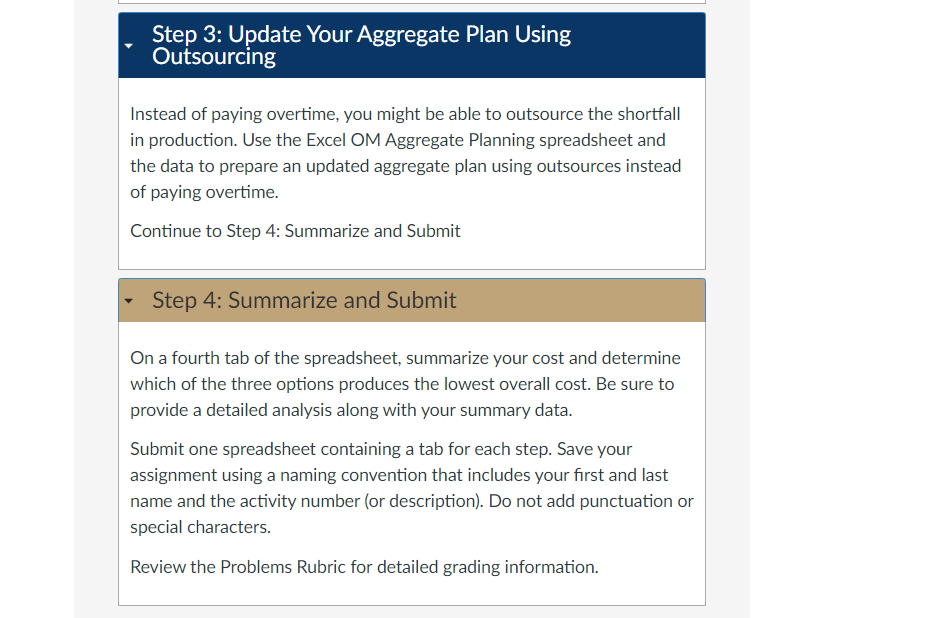

In the Module Overview, we stated that an "aggregate plan will include the quantity and timing of production for the intermediate future (typically 3-18 months ahead). Some factors such as demand, pay rate, and the ability to use overtime or subcontract some of the production must be taken into consideration to keep the total cost of production as low as possible. You have been asked to build the aggregate planning schedule for your factory for the next six months and to determine the best option. This chart provides the variables and cost for each variable. Variables Inventory carrying cost Subcontracting cost Average pay rate Overtime pay rate Labor-hours needed to produce one unit Units per day produced Beginning inventory Planned ending inventory Lost sales per unit Cost $7 per unit per month $25 per unit $12 per hour (8 hours per day) $18 per hour (above 8 hours per day) 1.5 hours per unit 50 o 0 $30 This chart provides the demand for the product and the number of production days per month. 0 Beginning inventory Planned ending inventory Lost sales per unit 0 $30 This chart provides the demand for the product and the number of production days per month. Months January February March April May June Demand 1300 800 600 1500 1300 1300 Production Days 22 18 21 21 22 20 Complete the steps in each section and then submit your assignment for grading. Submit one spreadsheet containing a tab for each step. Step 1: Prepare Your Aggregate Plan Use the Excel OM Aggregate Planning spreadsheet and the data to prepare your aggregate plan. Produce a graph of your plan. The intent is to use a level strategy (or level scheduling) with no overtime, no safety stock, and no subcontractors. Hint 1 - Consider that it takes 1.5 hours to produce a unit when determining your cost per unit for average and overtime pay. Hint 2 - To determine regular time production, you need to multiply the units per day produced by the number of production days. Continue to Step 2: Update Your Aggregate Plan Using Overtime Step 2: Update Your Aggregate Plan Using Overtime In the plan produced in Step 1, the production rate did not meet the total demand. If you were able to use overtime to meet the shortfall, what would your aggregate plan look like? Use the Excel OM Aggregate Planning spreadsheet and the data to prepare an updated aggregate plan. Continue to Step 3: Update Your Aggregate Plan Using Outsourcing Step 3: Update Your Aggregate Plan Using Outsourcing Instead of paying overtime, you might be able to outsource the shortfall in production. Use the Excel OM Aggregate Planning spreadsheet and the data to prepare an updated aggregate plan using outsources instead of paying overtime. Continue to Step 4: Summarize and Submit Step 4: Summarize and Submit On a fourth tab of the spreadsheet, summarize your cost and determine which of the three options produces the lowest overall cost. Be sure to provide a detailed analysis along with your summary data. Submit one spreadsheet containing a tab for each step. Save your assignment using a naming convention that includes your first and last name and the activity number (or description). Do not add punctuation or special characters. Review the Problems Rubric for detailed grading information. In the Module Overview, we stated that an "aggregate plan will include the quantity and timing of production for the intermediate future (typically 3-18 months ahead). Some factors such as demand, pay rate, and the ability to use overtime or subcontract some of the production must be taken into consideration to keep the total cost of production as low as possible. You have been asked to build the aggregate planning schedule for your factory for the next six months and to determine the best option. This chart provides the variables and cost for each variable. Variables Inventory carrying cost Subcontracting cost Average pay rate Overtime pay rate Labor-hours needed to produce one unit Units per day produced Beginning inventory Planned ending inventory Lost sales per unit Cost $7 per unit per month $25 per unit $12 per hour (8 hours per day) $18 per hour (above 8 hours per day) 1.5 hours per unit 50 o 0 $30 This chart provides the demand for the product and the number of production days per month. 0 Beginning inventory Planned ending inventory Lost sales per unit 0 $30 This chart provides the demand for the product and the number of production days per month. Months January February March April May June Demand 1300 800 600 1500 1300 1300 Production Days 22 18 21 21 22 20 Complete the steps in each section and then submit your assignment for grading. Submit one spreadsheet containing a tab for each step. Step 1: Prepare Your Aggregate Plan Use the Excel OM Aggregate Planning spreadsheet and the data to prepare your aggregate plan. Produce a graph of your plan. The intent is to use a level strategy (or level scheduling) with no overtime, no safety stock, and no subcontractors. Hint 1 - Consider that it takes 1.5 hours to produce a unit when determining your cost per unit for average and overtime pay. Hint 2 - To determine regular time production, you need to multiply the units per day produced by the number of production days. Continue to Step 2: Update Your Aggregate Plan Using Overtime Step 2: Update Your Aggregate Plan Using Overtime In the plan produced in Step 1, the production rate did not meet the total demand. If you were able to use overtime to meet the shortfall, what would your aggregate plan look like? Use the Excel OM Aggregate Planning spreadsheet and the data to prepare an updated aggregate plan. Continue to Step 3: Update Your Aggregate Plan Using Outsourcing Step 3: Update Your Aggregate Plan Using Outsourcing Instead of paying overtime, you might be able to outsource the shortfall in production. Use the Excel OM Aggregate Planning spreadsheet and the data to prepare an updated aggregate plan using outsources instead of paying overtime. Continue to Step 4: Summarize and Submit Step 4: Summarize and Submit On a fourth tab of the spreadsheet, summarize your cost and determine which of the three options produces the lowest overall cost. Be sure to provide a detailed analysis along with your summary data. Submit one spreadsheet containing a tab for each step. Save your assignment using a naming convention that includes your first and last name and the activity number (or description). Do not add punctuation or special characters. Review the Problems Rubric for detailed grading information