Question: show all work and explain 13. A production analyst and an industrial engineer have set a target batch size of 5 parts on the hydraulic

show all work and explain

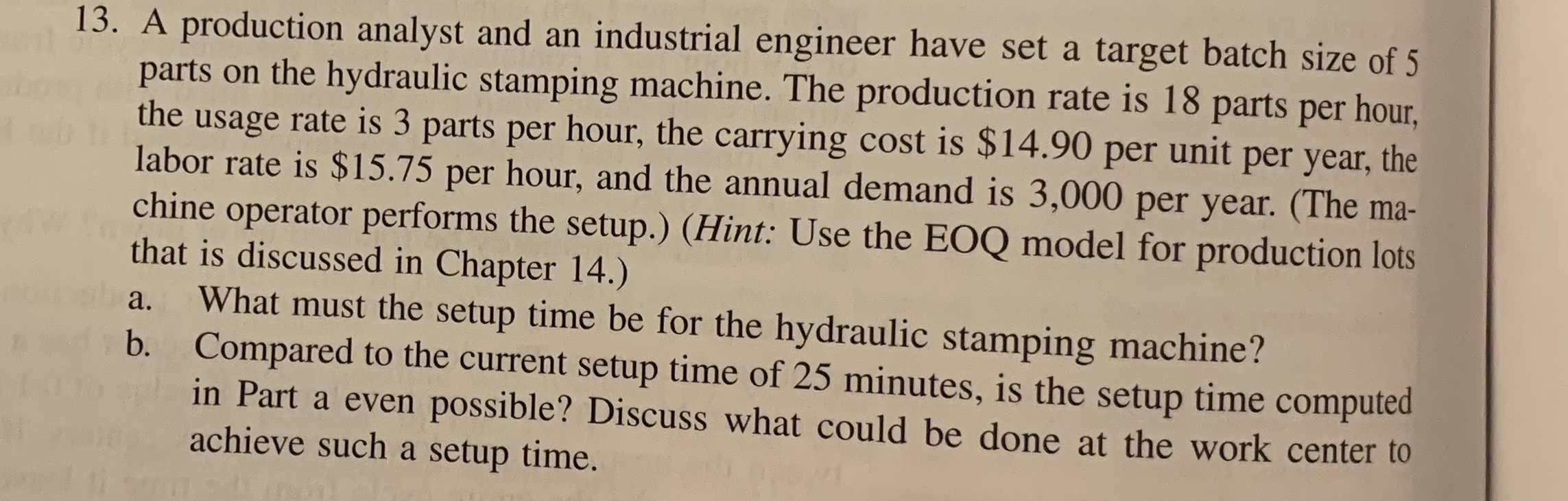

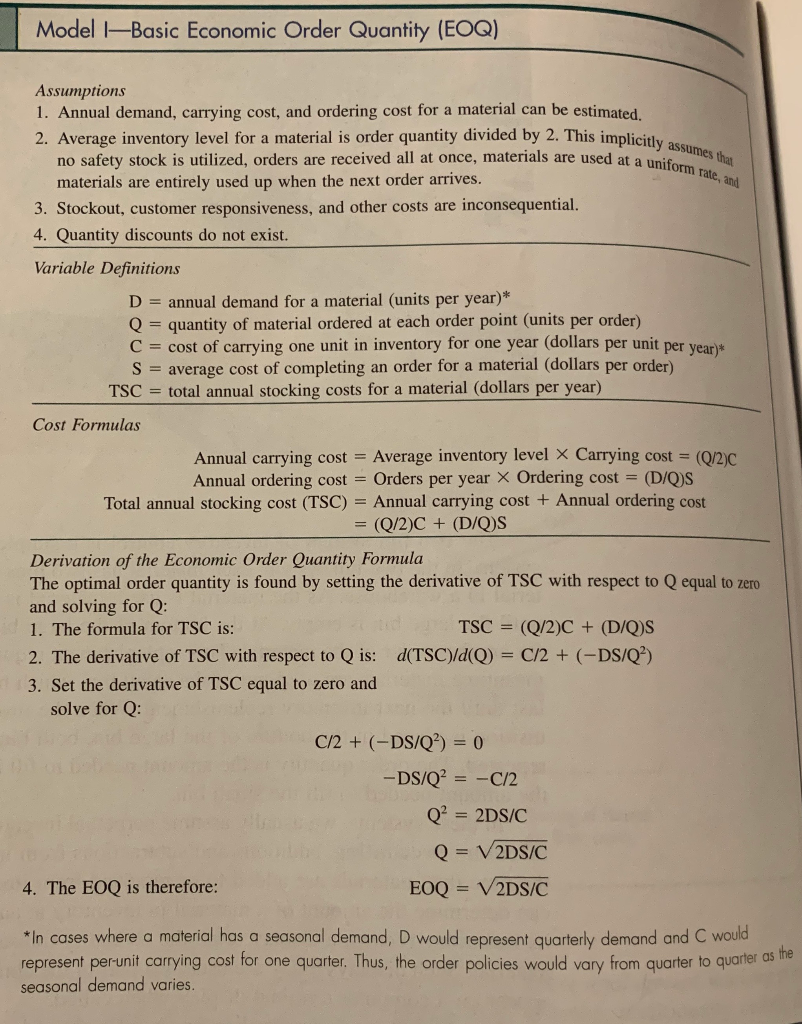

13. A production analyst and an industrial engineer have set a target batch size of 5 parts on the hydraulic stamping machine. The production rate is 18 parts per hour, the usage rate is 3 parts per hour, the carrying cost is $14.90 per unit per year, the labor rate is $15.75 per hour, and the annual demand is 3,000 per year. (The ma- chine operator performs the setup.) (Hint: Use the EOQ model for production lots that is discussed in Chapter 14.) a. What must the setup time be for the hydraulic stamping machine? b. Compared to the current setup time of 25 minutes, is the setup time computed in Part a even possible? Discuss what could be done at the work center to achieve such a setup time. Model Basic Economic Order Quantity (EOQ) e implicitly assumes than at a uniform rate, and Assumptions 1. Annual demand, carrying cost, and ordering cost for a material can be estimated. 2. Average inventory level for a material is order quantity divided by 2. This implicitly no safety stock is utilized, orders are received all at once, materials are used at a un materials are entirely used up when the next order arrives. 3. Stockout, customer responsiveness, and other costs are inconsequential. 4. Quantity discounts do not exist. Variable Definitions D = annual demand for a material (units per year)* Q = quantity of material ordered at each order point (units per order) C = cost of carrying one unit in inventory for one year (dollars per unit per years S = average cost of completing an order for a material (dollars per order) TSC = total annual stocking costs for a material (dollars per year) Cost Formulas Annual carrying cost = Average inventory level X Carrying cost = (Q/2) Annual ordering cost = Orders per year X Ordering cost = (D/QS Total annual stocking cost (TSC) = Annual carrying cost + Annual ordering cost = (Q/2) + (D/Q)S equal to zero Derivation of the Economic Order Quantity Formula The optimal order quantity is found by setting the derivative of TSC with respect to and solving for Q: 1. The formula for TSC is: TSC = (Q/2)C + (D/Q)S 2. The derivative of TSC with respect to Q is: d(TSC)/d(Q) = C/2 + (-DS/Q) 3. Set the derivative of TSC equal to zero and solve for Q: C/2 + (-DS/QY) = 0 -DS/Q = -/2 Q = 2DS/C Q = V2DS/C 4. The EOQ is therefore: EOQ = V2DS/C *In cases where a material has a seasonal demand, D would represent quarterly demand and C would represent per-unit carrying cost for one quarter. Thus, the order policies would vary from quarter to quarter o seasonal demand variesStep by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock