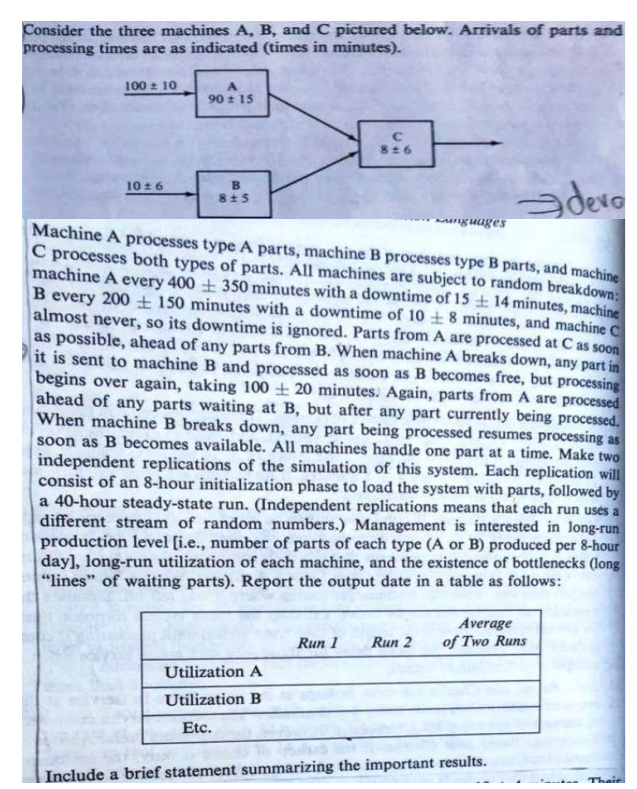

Question: ( simulating in ARENA ) Machine A processes type A parts, machine B processes type B parts, and machine C processes both types of parts.

(simulating in ARENA) Machine A processes type A parts, machine B processes type B parts, and machine C processes both types of parts. All machines are subject to random breakdown machine A every 400 350 minutes with a downtime of 15 14 minutes, machine B every 200 150 minutes with a downtime of 10 8 minutes, and machine C almost never, so its downtime is ignored. Parts from A are processed at C as soon as possible, ahead of any parts from B. When machine A breaks down, any part in it is sent to machine B and processed as soon as B becomes free, but processing begins over again, taking 100 20 minutes. Again, parts from A are processed ahead of any parts waiting at B, but after any part currently being processed. When machine B breaks down, any part being processed resumes processing as soon as B becomes available. All machines handle of part at a time. Make two independent replications of the simulation of this system. Each replication will consist of an 8-hour initialization phase to load the system with parts, followed by a 40-hour steady-state run. (Independent replications means that each run uses a different stream of random numbers. ) Management is interested in long-run production level [i.e., number of parts of each type (A or B) produced per 8- hour day), long-run utilization of each machine, and the existence of bottlenecks (long "lines" of waiting parts). Report the output date in a table at follows by simulating in ARENA.

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts