Question: Solve correctly and Do Not copy old answers! D5. Repeat Example 10-2 except calculate the diameter at the bottom of the column at a pressure

Solve correctly and Do Not copy old answers!

Solve correctly and Do Not copy old answers!

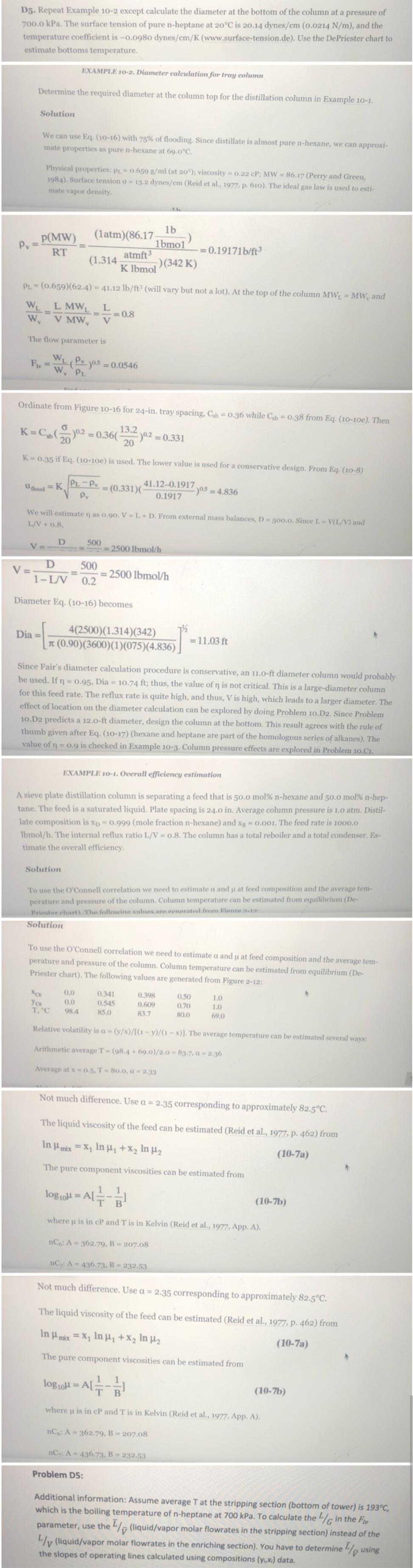

D5. Repeat Example 10-2 except calculate the diameter at the bottom of the column at a pressure of 700.0 kPa. The surface tension of pure n-heptane at 20C is 20.14 dynes/cm (0.0214 N/m), and the temperature coefficient is -0.0980 dynes/cm/K (www.surface-tension.de). Use the De Priester chart to estimate bottoms temperature. EXAMPLE 10-2. Diameter calculation for tray column Determine the required diameter at the column top for the distillation column in Example 10-1. Solution We can use Eq. (10-16) with 75% of flooding. Since distillate is almost pure n-hexane, we can approxi- mate properties as pure n-hexane at 69.0C. Physical properties: -0.659 g/ml (at 20); viscosity = 0.22 cP; MW = 86.17 (Perry and Green, 1984). Surface tension a = 13.2 dynes/em (Reid et al., 1977, p. 610). The ideal gas law is used to esti- mate vapor density, P(MW) Py = RT 1b (latm)(86.17 1bmo1 =0.19171b/ft3 atmft3 (1.314 ;) (342 K) K lbmol PL = (0.659)(62.4) = 41.12 lb/ft (will vary but not a lot), At the top of the column MW1 = MW, and W w L MW L =0.8 V V MW, The flow parameter is Fiv Wu Px 195 = 0.0546 W, PL Ordinate from Figure 10-16 for 24-in, tray spacing, Csb = 0.36 while Csb = 0.38 from Eq. (10-10e). Then K=C30 (47) 02 = 0.361 13.2 20 -)02 = 0.331 20 K = 0.35 if Eq. (10-10e) is used. The lower value is used for a conservative design. From Eq. (10-8) Ufood =K IPL-Py 41.12-0.1917 = (0.331) .)05 = 4.836 P 0.1917 We will estimate nas 0.90. V-L. D. From external mass balances, D = 500.0. Since L V(L/V) and L/V + 0.8 D VE 500 2500 lbmol/h D V= 1-LV 500 = 2500 lbmol/h 0.2 Diameter Eq. (10-16) becomes Dia = 4(2500)(1.314)(342) It (0.90)(3600)(1)(075)(4.836). = 11.03 ft Since Fair's diameter calculation procedure is conservative, an 11.0-ft diameter column would probably be used. If n = 0.95, Dia = 10.74 ft; thus, the value of n is not critical. This is a large-diameter column for this feed rate. The reflux rate is quite high, and thus, V is high, which leads to a larger diameter. The effect of location on the diameter calculation can be explored by doing Problem 10.D2. Since Problem 10.D2 predicts a 12.0-ft diameter, design the column at the bottom. This result agrees with the rule of thumb given after Eq. (10-17) (hexane and heptane are part of the homologous series of alkanes). The value of n = 0.9 is checked in Example 10-3. Column pressure effects are explored in Problem 10.C. EXAMPLE 10-1. Overall efficiency estimation A sieve plate distillation column is separating a feed that is 50.0 mol% n-hexane and 50.0 mol% n-hep- tane. The feed is a saturated liquid. Plate spacing is 24.0 in. Average column pressure is 1.0 atm. Distil- late composition is xp = 0.999 (mole fraction n-hexane) and Xp = 0.001. The feed rate is 1000.0 Ibmol/h. The internal reflux ratio L/V=0.8. The column has a total reboiler and a total condenser. Es- timate the overall efficiency Solution To use the O'Connell correlation we need to estimate a and ji at feed composition and the average tem- perature and pressure of the column Column temperature can be estimated from eguilibrium (De- Printer chart) The following values onerated from our Solution To use the O'Connell correlation we need to estimate a and u at feed composition and the average tem- perature and pressure of the column. Column temperature can be estimated from equilibrium (De- Priester chart). The following values are generated from Figure 2-12: 0.50 you T." 0.0 0.0 98.4 0.341 0.545 85.0 0.398 0.609 83.7 0.70 1.0 1.0 69.0 80.0 Relative volatility is a = (y/x)/[(1 - y)/(1 - x)]. The average temperature can be estimated several ways: Arithmetic average T - (98.4 + 69.0)/2.0 = 83.7. a = 2.36 Average at x = 0.5, T-80.0, a = 2.33 Not much difference. Use a = 2.35 corresponding to approximately 82.5C. The liquid viscosity of the feed can be estimated (Reid et al., 1977, p. 462) from In mix = x, In 4, + x2 In H2 (10-7a) The pure component viscosities can be estimated from logioh = AL 1 / 1 (10-7b) where ji is in cP and T is in Kelvin (Reid et al., 1977, App. A). nCo: A = 362.79, B = 207.08 nC: A = 436.73, B = 232.53 Not much difference. Use a = 2.35 corresponding to approximately 82.5C. The liquid viscosity of the feed can be estimated (Reid et al., 1977, p. 462) from In mix = X, In My + x2 In M2 (10-7a) The pure component viscosities can be estimated from logioh = A[: B. (10-7b) where is in cP and T is in Kelvin (Reid et al., 1977, App. A). nC6: A = 362.79, B = 207.08 nC : A = 436.73, B = 232.53 Problem D5: Additional information: Assume average T at the stripping section (bottom of tower) is 193C, which is the boiling temperature of n-heptane at 700 kPa. To calculate the 4G in the Fiv parameter , use the 1/7 (liquid/vapor molar flowrates in the stripping section) instead of the y (liquid/vapor molar flowrates in the enriching section). You have to determine y using the slopes of operating lines calculated using compositions (y,xi) data

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts