Question: Suppose that a design office uses a Co - ordinate Measuring Machine ( CMM ) in measuring dimensions and geometries of different products for different

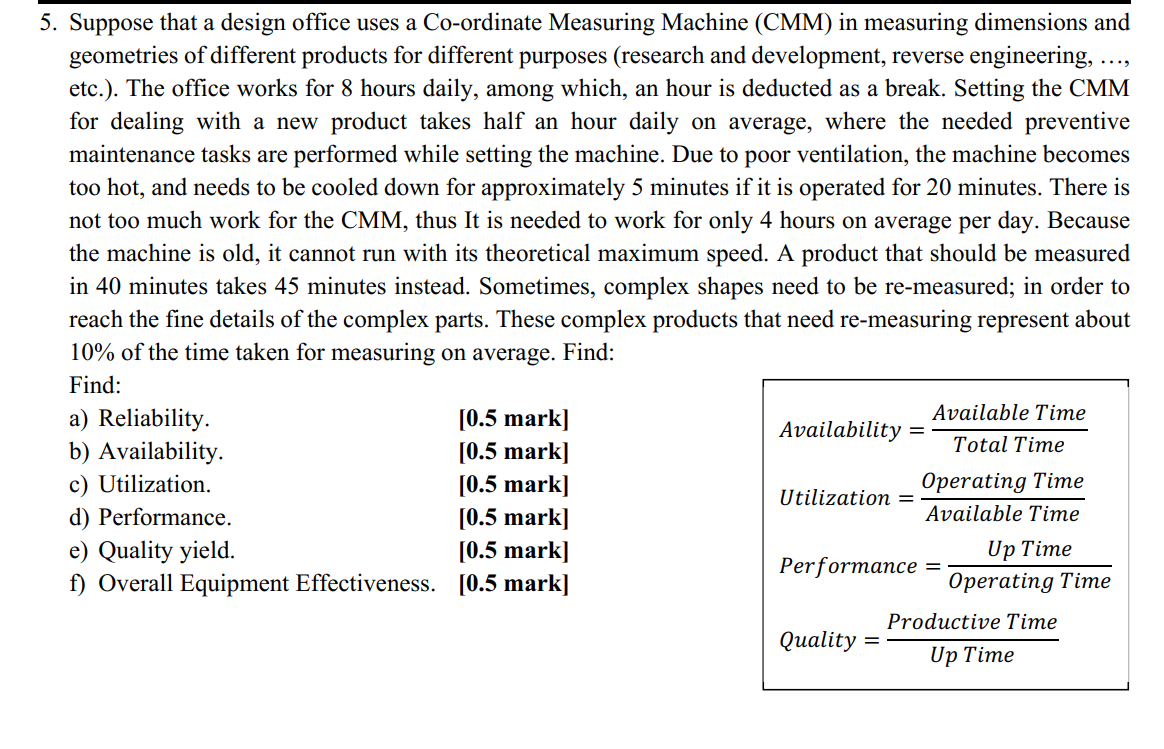

Suppose that a design office uses a Coordinate Measuring Machine CMM in measuring dimensions and

geometries of different products for different purposes research and development, reverse engineering,

etc. The office works for hours daily, among which, an hour is deducted as a break. Setting the CMM

for dealing with a new product takes half an hour daily on average, where the needed preventive

maintenance tasks are performed while setting the machine. Due to poor ventilation, the machine becomes

too hot, and needs to be cooled down for approximately minutes if it is operated for minutes. There is

not too much work for the CMM thus It is needed to work for only hours on average per day. Because

the machine is old, it cannot run with its theoretical maximum speed. A product that should be measured

in minutes takes minutes instead. Sometimes, complex shapes need to be remeasured; in order to

reach the fine details of the complex parts. These complex products that need remeasuring represent about

of the time taken for measuring on average. Find:

Find:

a Reliability.

mark

b Availability. mark

c Utilization. mark

d Performance. mark

e Quality yield. mark

f Overall Equipment Effectiveness. mark

Availability

Utilization

Performance

Quality

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock