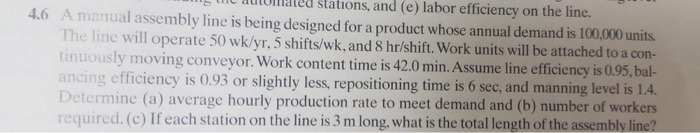

Question: t nc automated stations, and (e) labor efficiency on the line. 4.6 A manual assembly line is being designed for a product whose annual demand

t nc automated stations, and (e) labor efficiency on the line. 4.6 A manual assembly line is being designed for a product whose annual demand is 100,000 units The line will operate 50 wk/yr, 5 shifts/wk, and 8 hr/shift. Work units will be attached to a con- moving conveyor. Work content time is 42.0 min.Assume line efficiency is 0.95, bal- is 0.93 or slightly less, repositioning time is 6 sec, and manning level is 1.4 Determine (a) average hourly production rate to meet demand and (b) number of workers required. (c) If each station on the line is 3 m long, what is the total length of the assembly line? ancing efficiency

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts