Question: TABLE 11.3 Supply Chain Risks and Tactics OM in the News: Hobbled U.S. Supply Chains JUNE 8, 2020 by Barry Render Wanxiang America's automotive components

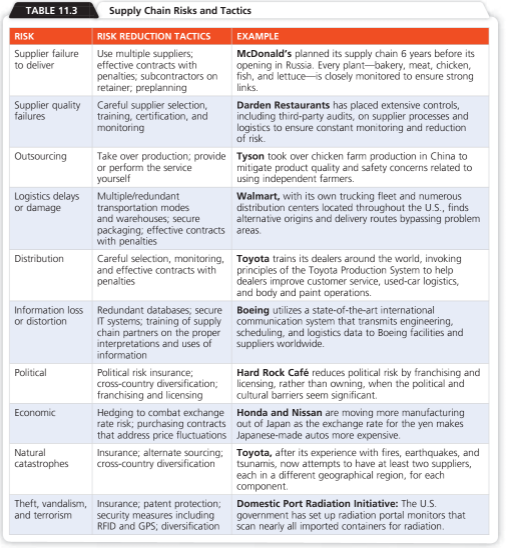

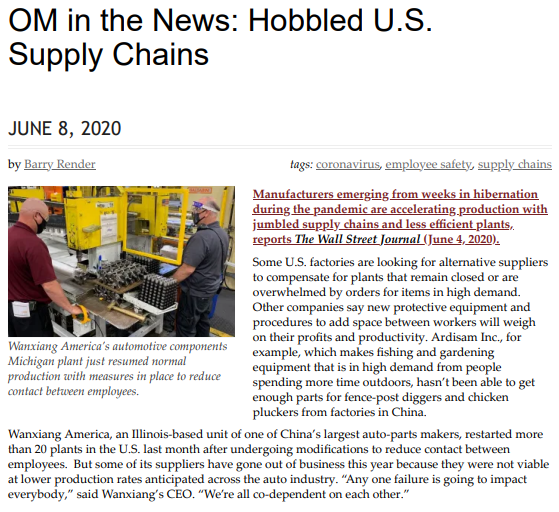

TABLE 11.3 Supply Chain Risks and Tactics OM in the News: Hobbled U.S. Supply Chains JUNE 8, 2020 by Barry Render Wanxiang America's automotive components Michigan plant just resumed normal production with measures in place to reduce contact between employees. tags: coronavirus, employee safety, supply chains Manufacturers emerging from weeks in hibernation during the pandemic are accelerating.production with jumbled supply chains and less efficient plants. reports The Wall Street Joumal (June 4,2020). Some U.S. factories are looking for alternative suppliers to compensate for plants that remain closed or are overwhelmed by orders for items in high demand. Other companies say new protective equipment and procedures to add space between workers will weigh on their profits and productivity. Ardisam Inc., for example, which makes fishing and gardening equipment that is in high demand from people spending more time outdoors, hasn't been able to get enough parts for fence-post diggers and chicken pluckers from factories in China. Wanxiang America, an Illinois-based unit of one of China's largest auto-parts makers, restarted more than 20 plants in the U.S. last month after undergoing modifications to reduce contact between employees. But some of its suppliers have gone out of business this year because they were not viable at lower production rates anticipated across the auto industry. "Any one failure is going to impact everybody," said Wanxiang's CEO. "We're all co-dependent on each other." GM last month delayed plans to increase production of pickup trucks because of a shortage of parts from Mexico. O-I Glass, the biggest producer of glass bottles, is using more expensive raw materials to make glass because of a shortage of recycled glass. The volume of recycled glass from states with deposits on beverage bottles plunged by 2/3 after redemptions on empties were suspended as a safety precaution for retail workers. "We've built our supply chains based on recycling," said an O-I Glass exec. Housewares company Honey Can-Do International said its overhead costs have climbed, because its distribution center is less efficient with operations reconfigured to separate employees. Classroom discussion questions: 1. What seem to be the major problems firms are facing as they restart production? 2. Which of the supply chain risks listed in Table 11.3 in your Heizer/Render/Munson OM text relate to the pandemic? TABLE 11.3 Supply Chain Risks and Tactics OM in the News: Hobbled U.S. Supply Chains JUNE 8, 2020 by Barry Render Wanxiang America's automotive components Michigan plant just resumed normal production with measures in place to reduce contact between employees. tags: coronavirus, employee safety, supply chains Manufacturers emerging from weeks in hibernation during the pandemic are accelerating.production with jumbled supply chains and less efficient plants. reports The Wall Street Joumal (June 4,2020). Some U.S. factories are looking for alternative suppliers to compensate for plants that remain closed or are overwhelmed by orders for items in high demand. Other companies say new protective equipment and procedures to add space between workers will weigh on their profits and productivity. Ardisam Inc., for example, which makes fishing and gardening equipment that is in high demand from people spending more time outdoors, hasn't been able to get enough parts for fence-post diggers and chicken pluckers from factories in China. Wanxiang America, an Illinois-based unit of one of China's largest auto-parts makers, restarted more than 20 plants in the U.S. last month after undergoing modifications to reduce contact between employees. But some of its suppliers have gone out of business this year because they were not viable at lower production rates anticipated across the auto industry. "Any one failure is going to impact everybody," said Wanxiang's CEO. "We're all co-dependent on each other." GM last month delayed plans to increase production of pickup trucks because of a shortage of parts from Mexico. O-I Glass, the biggest producer of glass bottles, is using more expensive raw materials to make glass because of a shortage of recycled glass. The volume of recycled glass from states with deposits on beverage bottles plunged by 2/3 after redemptions on empties were suspended as a safety precaution for retail workers. "We've built our supply chains based on recycling," said an O-I Glass exec. Housewares company Honey Can-Do International said its overhead costs have climbed, because its distribution center is less efficient with operations reconfigured to separate employees. Classroom discussion questions: 1. What seem to be the major problems firms are facing as they restart production? 2. Which of the supply chain risks listed in Table 11.3 in your Heizer/Render/Munson OM text relate to the pandemic

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts