Question: Task 1 - ( A ) Factory Maintenance Problem Problem background Part of a factory that manufactures extruded building products is shown in fig 2

Task A Factory Maintenance Problem

Problem background

Part of a factory that manufactures extruded building products is shown in fig Dust that is processed in another factory is loaded by a wheeled shovel irto a hopper and is raised via an inclined conveyor and bucket elevator to the top of the system. The dust is then distributed to storage hoppers by a large scraper chain conveyor.

Each hopper is equipped with an extract conveyor which icads dust onto a collection conveyor and then onto the machine feed corrveyor.

The machine hopper acts as a surge hopper, allowing an even and controllable feed of dust to be added to the mixer of the main extrusion machine.

Much ancillary equipment has been excluded for clarity.

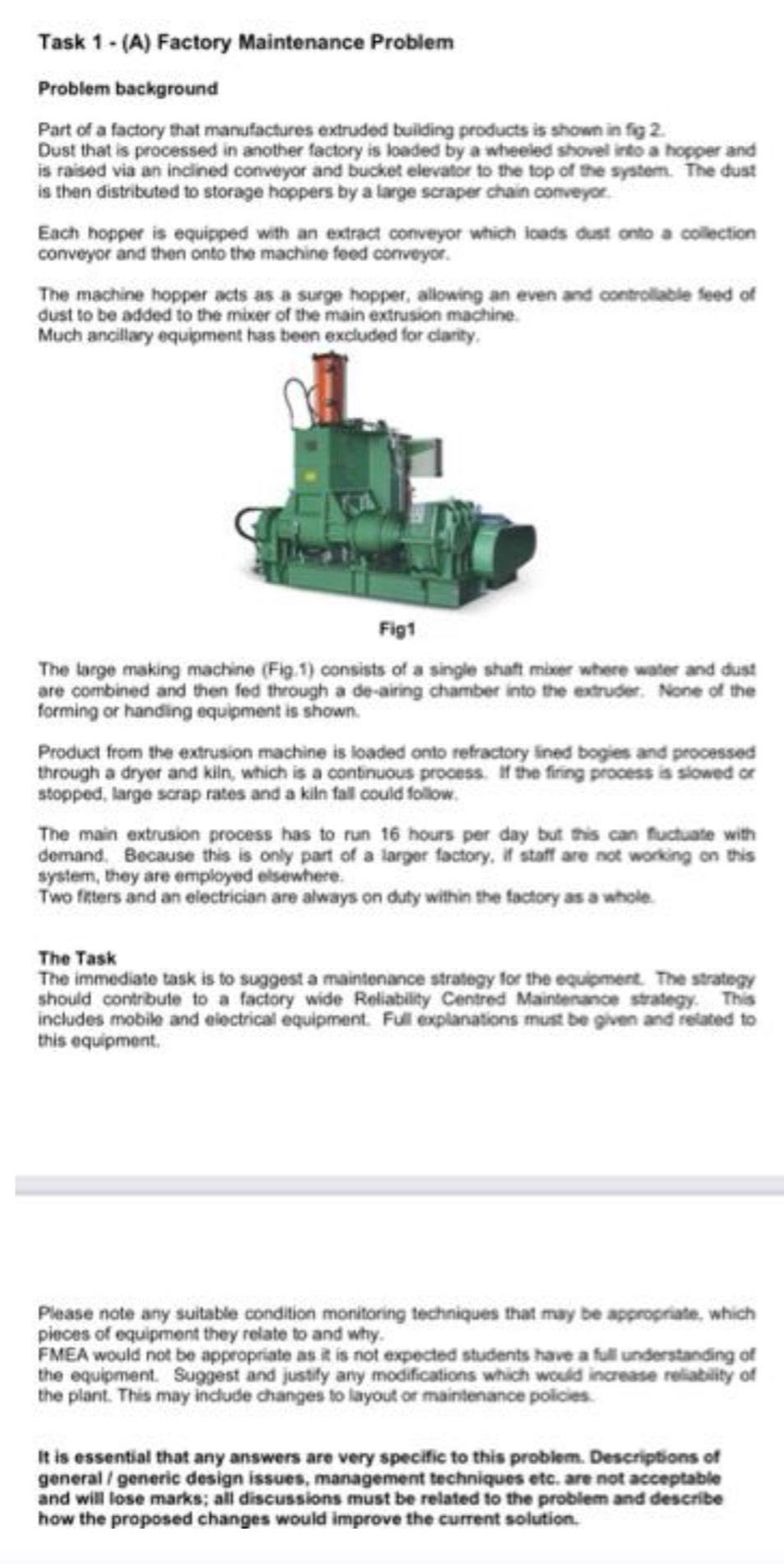

The targe making machine Fig consists of a single shaft mixer where water and dust are combined and then fed through a deairing chamber into the extruder. None of the forming or handing equipment is shown.

Product from the extrusion machine is loaded onto refractory lined bogies and processed through a dryer and kiln, which is a continuous process. If the firing process is slowed or stopped, large scrap rates and a kiln fall could follow.

The main extrusion process has to run hours per day but this can fuctuate with demand. Because this is only part of a largor factory, if staff are not working on this system, they are employed elsewhere.

Two fiters and an electrician are always on duty within the factory as a whole.

The Task

The immediate task is to suggest a maintenance strategy for the equipment. The strategy should contribute to a factory wide Reliability Centred Maintenance strategy. This includes mobile and electrical equipment. Full explanations must be given and related to this equipment.

Please note any suitable condition monitoning techniques that may be appropriate, which pieces of equipment they relate to and why.

FMEA would not be appropriate as it is not expected students have a full understanding of the equipment. Suggest and justify ary modificaticns which would increase reliability of the plant. This may include changes to layout or maintenance policies.

It is essential that any answers are very specific to this problem. Descriptions of general generic design issues, management techniques etc, are not acceptable and will lose marks; all discussions must be related to the problem and describe how the proposed changes would improve the current solution.

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock