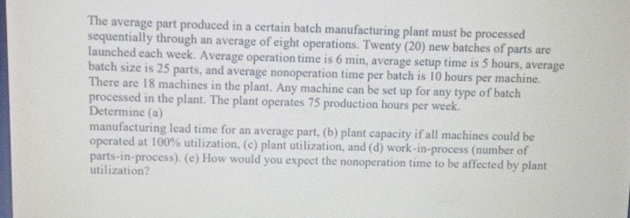

Question: The average part produced in a certain batch manufacturing plant must be processed sequentially through an average of eight operations. Twenty ( 2 0 )

The average part produced in a certain batch manufacturing plant must be processed sequentially through an average of eight operations. Twenty new batches of parts are launched each week. Average operation time is min, average setup time is hours, average batch size is parts, and average nonoperation time per batch is hours per machine. There are machines in the plant. Any machine can be set up for any type of bateh processed in the plant. The plant operates production hours per week. Determine a manufacturing lead time for an average part, b plant capacity if all machines could be operated at utilization, c plant utilization, and d workinprocess number of partsinprocesse How would you expect the nonoperation time to be affected by plant utilization?

Step by Step Solution

There are 3 Steps involved in it

1 Expert Approved Answer

Step: 1 Unlock

Question Has Been Solved by an Expert!

Get step-by-step solutions from verified subject matter experts

Step: 2 Unlock

Step: 3 Unlock