Question: The demand for subassembly S is 80 units in week 7. Each unit of S requires 1 unit of T and 2 units of U.

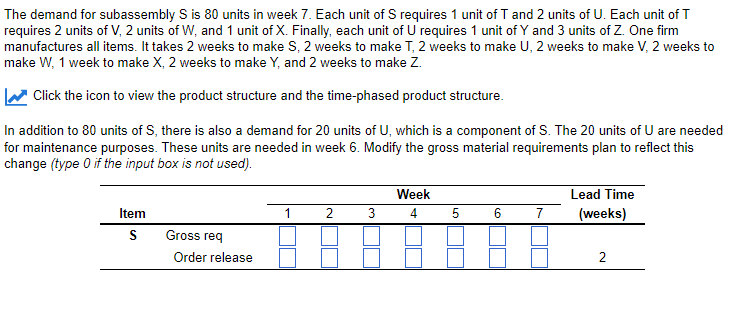

The demand for subassembly S is 80 units in week 7. Each unit of S requires 1 unit of T and 2 units of U. Each unit of T requires 2 units of V, 2 units of W, and 1 unit of X. Finally, each unit of U requires 1 unit of Y and 3 units of Z. One firm manufactures all items. It takes 2 weeks to make S, 2 weeks to make T, 2 weeks to make U, 2 weeks to make V, 2 weeks to make W, 1 week to make X, 2 weeks to make Y, and 2 weeks to make Z. Click the icon to view the product structure and the time-phased product structure. In addition to 80 units of S, there is also a demand for 20 units of U, which is a component of S. The 20 units of U are needed for maintenance purposes. These units are needed in week 6. Modify the gross material requirements plan to reflect this change (type 0 if the input box is not used). Week Lead Time Item 1 2 3 4 5 6 7 (weeks) S Gross req Order release 2

The demand for subassembly S is 80 units in week 7. Each unit of S requires 1 unit of T and 2 units of U. Each unit of T requires 2 units of V, 2 units of W, and 1 unit of X. Finally, each unit of U requires 1 unit of Y and 3 units of Z. One firm manufactures all items. It takes 2 weeks to make S, 2 weeks to make T, 2 weeks to make U, 2 weeks to make V, 2 weeks to make W, 1 week to make X, 2 weeks to make Y, and 2 weeks to make Z. Click the icon to view the product structure and the time-phased product structure. In addition to 80 units of S, there is also a demand for 20 units of U, which is a component of S. The 20 units of U are needed for maintenance purposes. These units are needed in week 6. Modify the gross material requirements plan to reflect this change (type 0 if the input box is not used). Week Lead Time Item 1 2 3 4 5 6 7 (weeks) S Gross req Order release 2

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts