Question: The desired process flow temperature should be held at 365C 1C. To accomplish this, you have been asked whether an available shell and tube heat

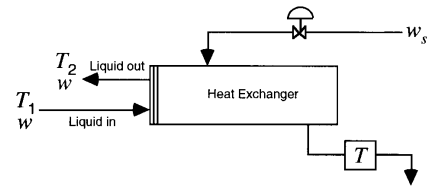

The desired process flow temperature should be held at 365C 1C. To accomplish this, you have been asked whether an available shell and tube heat exchanger could work for your plant. Your supervisor has suggested using a simple PI feedback controller, but you have found that the steam supply pressure changes by up to 10% regularly. Therefore, you believe a feedforward controller will be safer and worth the extra money to develop the necessary control model relating this disturbance to the process flow temperature coming from the heat exchanger.

a) For the heat exchanger design shown above using a Feedforward with Feedback Trim control system, draw the approximate P&ID configuration showing transmitters, sensors, controllers, and the process

b) Next, draw the block flow diagram for this system showing the transfer functions for each box

c) Finally, discuss each transfer function in terms of the process dynamics of each and comment on which blocks are controlled and which can be simplified. Also, discuss the advantages and disadvantages of the feedforward with feedback trim for this system

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts