Question: The overall average on a process you are attempting to monitor is 50.0 units. The process population standard deviation is 1.84 . Sample size is

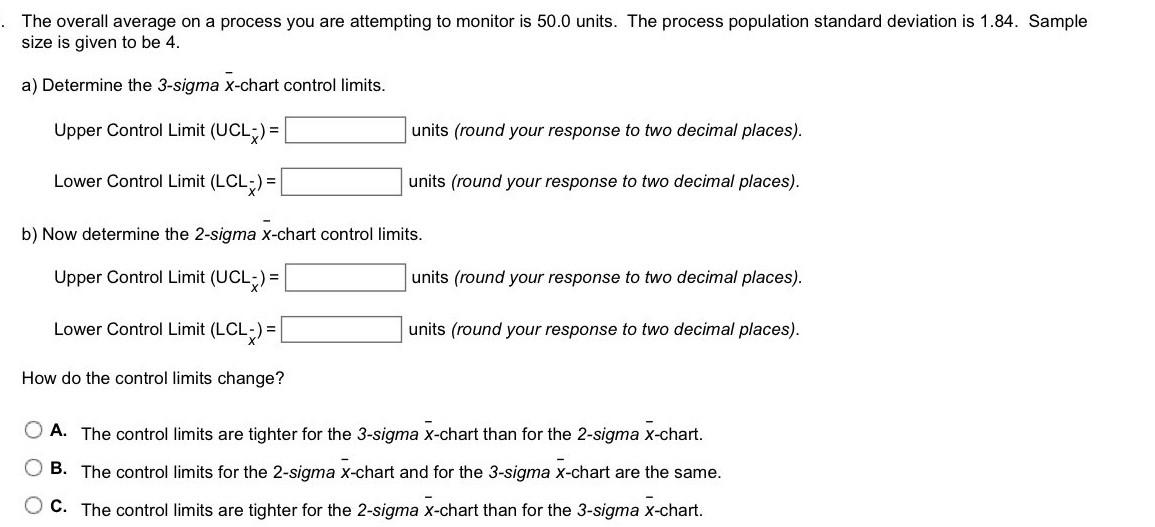

The overall average on a process you are attempting to monitor is 50.0 units. The process population standard deviation is 1.84 . Sample size is given to be 4 . a) Determine the 3-sigma x-chart control limits. Upper Control Limit (UCL)= units (round your response to two decimal places). Lower Control Limit (LCLx)= units (round your response to two decimal places). b) Now determine the 2 -sigma x-chart control limits. Upper Control Limit (UCLx)= units (round your response to two decimal places). Lower Control Limit (LCL)= units (round your response to two decimal places). How do the control limits change? A. The control limits are tighter for the 3-sigma x-chart than for the 2-sigma x-chart. B. The control limits for the 2-sigma x-chart and for the 3-sigma x-chart are the same. C. The control limits are tighter for the 2-sigma x-chart than for the 3-sigma x-chart. The overall average on a process you are attempting to monitor is 50.0 units. The process population standard deviation is 1.84 . Sample size is given to be 4 . a) Determine the 3-sigma x-chart control limits. Upper Control Limit (UCL)= units (round your response to two decimal places). Lower Control Limit (LCLx)= units (round your response to two decimal places). b) Now determine the 2 -sigma x-chart control limits. Upper Control Limit (UCLx)= units (round your response to two decimal places). Lower Control Limit (LCL)= units (round your response to two decimal places). How do the control limits change? A. The control limits are tighter for the 3-sigma x-chart than for the 2-sigma x-chart. B. The control limits for the 2-sigma x-chart and for the 3-sigma x-chart are the same. C. The control limits are tighter for the 2-sigma x-chart than for the 3-sigma x-chart

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts