Question: Apply your knowledge of Relay Logic Instructions to design a program that will Monitor and Control the filling of a tank. The program you create

Apply your knowledge of Relay Logic Instructions to design a program that will Monitor and Control the filling of a tank. The program you create will monitor and control this equipment while adhering to the following criteria:

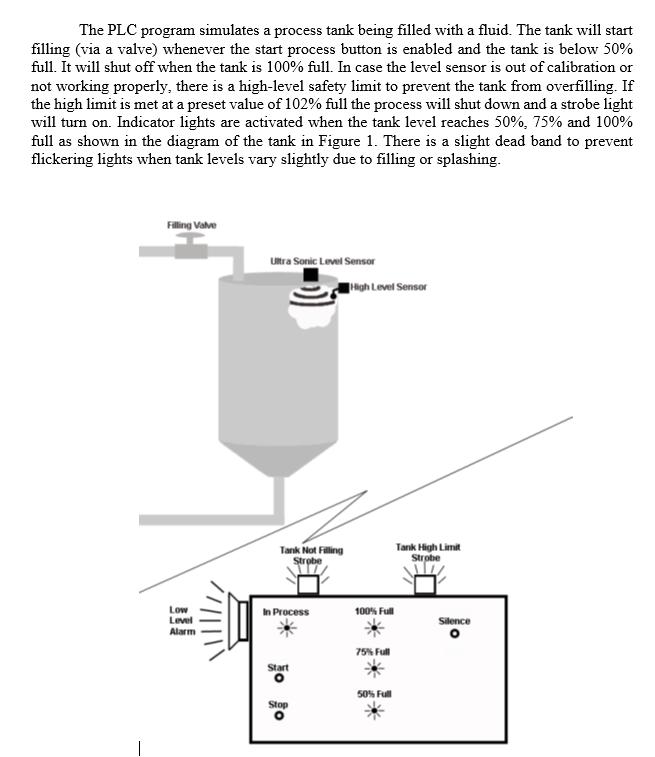

The PLC program simulates a process tank being filled with a fluid. The tank will start filling (via a valve) whenever the start process button is enabled and the tank is below 50% full. It will shut off when the tank is 100% full. In case the level sensor is out of calibration or not working properly, there is a high-level safety limit to prevent the tank from overfilling. If the high limit is met at a preset value of 102% full the process will shut down and a strobe light will turn on. Indicator lights are activated when the tank level reaches 50%, 75% and 100% full as shown in the diagram of the tank in Figure 1. There is a slight dead band to prevent flickering lights when tank levels vary slightly due to filling or splashing. Filing Valve Utra Sonic Level Sensor gh Level Sensor Tank Not Filling Strobe Tank High Limit Strobe Low In Process 100% Full Level Silence Alarm 75% Full Start 50% Full Stop

Step by Step Solution

3.45 Rating (158 Votes )

There are 3 Steps involved in it

The question has only information of the system of level control of a single tank but what is requir... View full answer

Get step-by-step solutions from verified subject matter experts